Horizontal Alcohol Spout Pouch Doypack Packing Machine With Explosion-Proof Machine

Model: LDSP-210

Application:

Automatic alcohol horizontal spout pouch doypack packing machine suitable for alcohol, liquor, cocktails, brandy, vodka, hand sanitizer, mouthwash, sauce, tomato sauce, olive oil, salad dressing, chili sauce, jam, peanut butter, chocolate sauce, shampoo, etc.

Application:

Automatic alcohol horizontal spout pouch doypack packing machine suitable for alcohol, liquor, cocktails, brandy, vodka, hand sanitizer, mouthwash, sauce, tomato sauce, olive oil, salad dressing, chili sauce, jam, peanut butter, chocolate sauce, shampoo, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

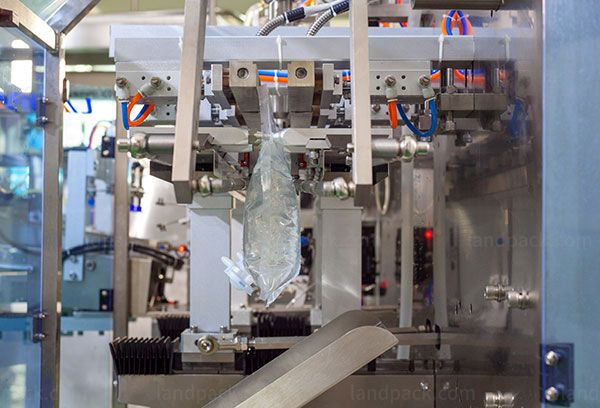

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

1. Different machine models are available to meet a wide range of premade bag sizes.

2. Customized main machine structure for various kinds of bag shapes. Like doypack zipper bag, 3/ 4 side seal bag, spout pouch, stand-up bag and irregular bag, etc.

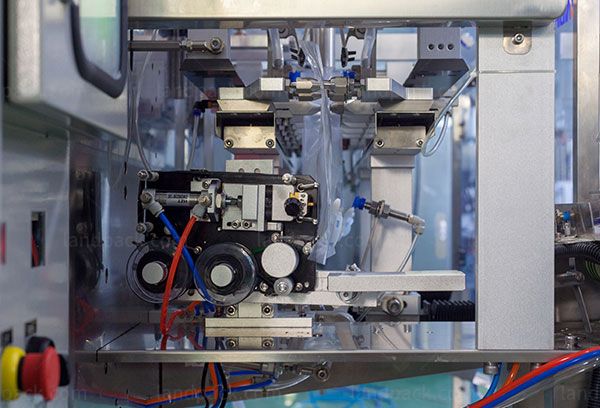

3. With an upgraded PLC control system, easy to operate on the touch screen of parameter settings.

4. Machine can equipment with different metering systems like a weigher, liquid pump, auger filler, and bucket chain for different kinds of product filling and packing in premade bags.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail