Automatic Nitrogen Packing Machine For Almond Snacks Cereals Nuts Etc

Model : LDHS-420A

Application :

The automatic nitrogen packing machine is designed for a wide range of granulated food products, such as snacks, chips, popcorn, cereals, oats, beans, nuts, candies, fried food, pet food, frozen food, hardware, and more. It ensures precise packaging with nitrogen flushing for freshness and extended shelf life.

Application :

The automatic nitrogen packing machine is designed for a wide range of granulated food products, it ensures precise packaging with nitrogen flushing for freshness and extended shelf life.

Examples :

Almond, snacks, chips, popcorn, cereals, oats, beans, nuts, candies, fried food, pet food, frozen food, hardware, and more.

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample :

| Model | LD-420 | LD-520 | LD-720 | LD-900 | LD-1050 | LD-1200 |

| Film Thickness | 0.04-0.08mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 80-350mm | 100-500mm | 100-600mm | 100-800mm | 100-1000mm |

| Bag Width | 60-200mm | 100-250mm | 180-350mm | 260-430mm | 290-505mm | 290-580mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | 400mm | 400mm | 400mm |

| Pakaging Rate | 5-60bag/min | 5-60bag/min | 5-55bag/min | 5-20bag/min | 5-20bag/min | 5-20bag/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.720mm | Max.900mm | Max.900mm | Max.1200mm |

| Measurement Range | 150-1500ml | 5-2000ml | 4000ml | 1-25L | 1-25L | 1.5L-45L |

| Combined Parts | LD series main frame, multi-heads weigher, Nitrogen Generator, Z type bucket elevator, Vibration feeder, Supporting platform, Product conveyor. | |||||

1.High-Precision Multi-Head Weigher: Improves both the speed and accuracy of measurement, enabling efficient packing operations.

2.User-Friendly Interface: The 7-inch touch screen simplifies operation, supporting multiple languages for greater convenience.

3.Reliable Control System: The imported PLC system ensures smooth machine operation with easy adjustments for different parameters.

4.Memory Function: Stores up to 10 product parameters for quick and hassle-free switching between product types.

5.Customizable Temperature Control: The independent PID temperature controller accommodates different packing materials for optimal sealing.

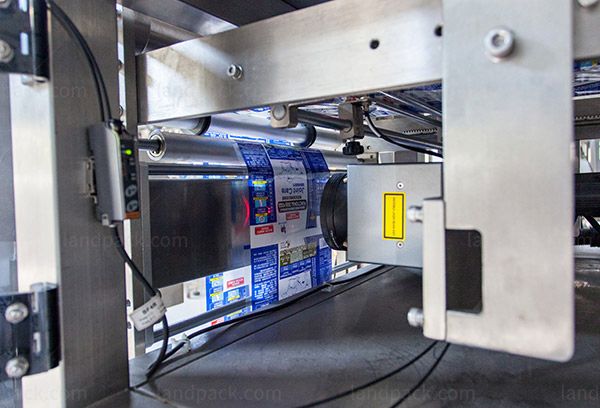

6.Enhanced Film Handling: The multi-union roll film system ensures smooth, efficient film feeding and reduces film-related issues.

7.Stable Film Transport: Dual servo-driven system guarantees reliable film feeding, resulting in consistently well-formed bags.

8.Superior Sealing Performance: The advanced sealing framework ensures reliable bag sealing and precise cutting, every time.

9.Fully Automated Process: The machine automatically handles filling, metering, bag forming, sealing, date printing, and packing, reducing labor requirements.

10.Efficient and Low-Waste Operation: Features low product loss and saves on labor costs, with easy maintenance and operation.

11.Increased Packaging Speed: The reciprocating mechanism improves overall packaging throughput.

12.Optimized Filling Process: The multi-head electronic scale with a dimpled surface reduces friction, enhancing product filling accuracy.

13.Environmentally-Friendly Laser Coding: Laser coding reduces material waste and is a more eco-conscious alternative for marking products.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail