Small Premade Pouch Almond Fill And Seal Machine

Model: LD-300A

Advantage:

With the advanced control system, many automatic functions can be realized, such as automatic counting, and weighing, etc.

Application:

It can flexibly adapt to bags of various specifications for packaging to improve production efficiency. Suitable for various granule materials in premade pouch style, such as almonds, nuts, hazelnut, peanut, pistachio, macadamia nut, cashew, sunflower seeds, peanut, etc.

Application:

Small premade pouch almond fill and seal machine, it can flexibly adapt to bags of various specifications for packaging to improve production efficiency.

Examples:

Almonds, nuts, hazelnut, peanut, pistachio, macadamia nut, cashew, sunflower seeds, peanut, etc.

Kindly Reminder:

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Product weight

3. Premade Bag/ Zipper Bag/ Sachet dimension

4. Premade Bag/ Zipper Bag/ Sachet material

Packaging Exambers:

| Model | LD-300A/LD--430A |

|---|---|

| Bag Material | Multilayer Composite Premade Bag(e.g.: PET/PE) |

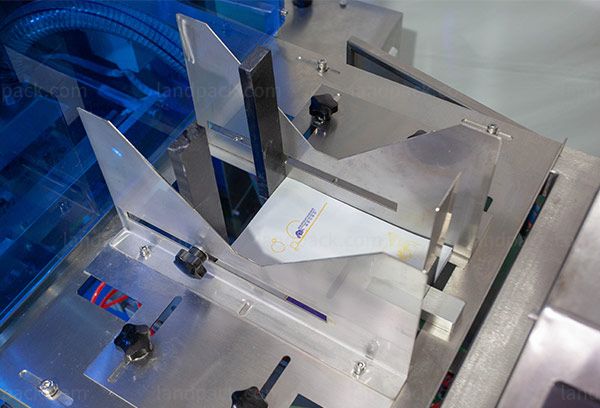

| Bag Type | 3 Side Seal Bag, Stand-up Bag, Zipper Bag, Premade Bag |

| Upgradable Bag Type | Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device) |

| Size Range | 80mm≤W≤300mm, 100mm≤L≤400mm |

| Speed | 0-15bags/min |

| Sealing Type | Straight grain, the pitch is 1mm (Optional reticulate) |

| Sealing Width | 10mm (5-20mm can be customized) |

| Voltage | 220V, Single-phase, 50/60HZ, 1.2KW |

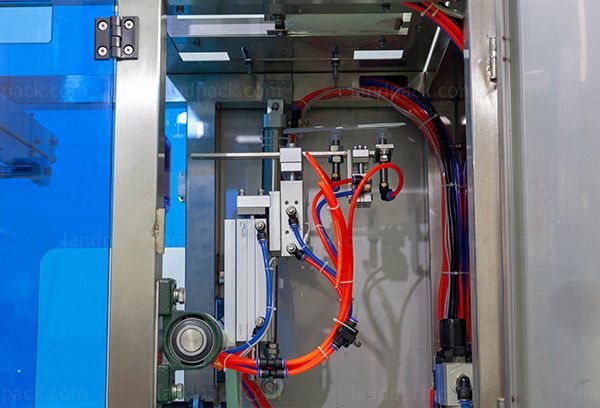

| Air Pressure | 0.65Mpa |

| Air Consumption | 0.3m³/min (Standard machine, no additional function) |

| Body Dimension | 1770*600*1260mm |

| Packing Dimension | 1860*710*1650mm (Export non-fumigation wooden case) |

Basic Configurations:

Touch Screen: China Kinco 7 inches color touch screen;

Languages: Chinese, English, Spanish, Dutch, Italian, Korean (At most three languages);

PLC: Japan Panasonic;

Cylinder: Taiwai Airtac (Can be upgraded to Japan SMC);

Vacuum Generator: China Airbest (Can be upgraded to Vacuum Pump);

Vacuum Component: Japan SMC;

Modular Control System For Vacuum Pressure: Japan SMC;

Modular Control System For Temperature: China YUDIAN;

Electrical Component: Schneider / Omron;

Safety Key Interlock Switch;

The main structure of the machine is SUS304 (The thickness of the rack is 3.0mm), and the material of the part is aluminum;

The part (Hopper) in contact with the material is SUS304 (Can be upgraded to SUS316L).

Basic Functions:

The machine stops running when the safety key interlock switch is pulled out;

No bag prompting function;

Self-diagnosis function of opening the bag failed (The bag can be reused); In that case, the machine will not fill and seal, it will re-take the bag;

Positioning (anti-dropping) function of the hopper;

Warning function of cartridge heater fault ;

Warning function of cylinder fault.

Warning function which air pressure is not up to standard.

Performance Features:

Easy to operate and easy to replace the bag / The machine is suitable for a variety of bag types;

Low maintenance cost / Modular replacement of the parts;

Certificate of Conformity.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail