Full Automatic Aluminum Metal Tube Filling And Sealing Machine

Model: LFW-QJ-006

Application:

Full automatic aluminum metal tube filling and sealing machine(LFW-QJ-006), it is suitable for medicine, food, cosmetics, daily chemical industry and other industries to fill and seal metal hoses. It can smoothly and accurately inject various paste, paste, fluids of any viscosity and other materials into the tube, and complete the folding and sealing, batch number, production date, etc.

Application:

Full automatic aluminum metal tube filling and sealing machine(LFW-QJ-006), it is suitable for medicine, food, cosmetics, daily chemical industry and other industries to fill and seal metal hoses. It can smoothly and accurately inject various paste, paste, fluids of any viscosity and other materials into the tube, and complete the folding and sealing, batch number, production date, etc.

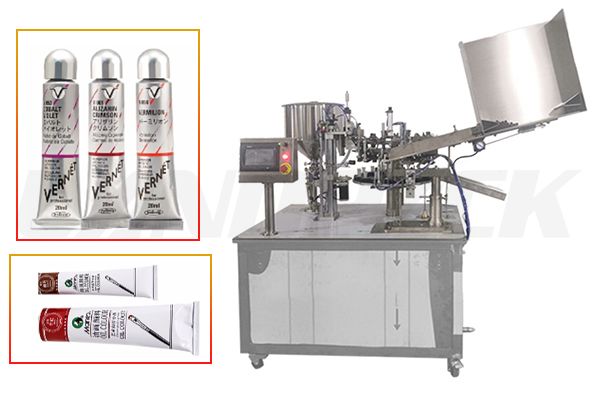

Packing Examples: ointment, adhesive, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste and other liquid or paste-like materials filling and sealing.

Filling container: Aluminum tube, various metal spft tube.

Optional Supporting Devices: three-dimensional packaging machine, cartoning machine, sealing and cutting machine, heat shrinking machine, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Description of the main packaging process:

The entire process of tube supply, tube washing, label identification, filling, folding and sealing, coding, and tube discharge is completed by the fully automatic control system;

Parameter:

| Model | LFW-QJ-006 |

| Supply voltage (V/Hz) | AC 220/50 110/60 |

| The hose material | Aluminum tube, various metal spft tube. |

| Power | 1.5KW |

| The hose diameter | 11-16mm |

| Gas source (Mpa) | 0.6-0.8(MPa) |

| Filling range (Ml) | 1-20 5-75(ml) |

| After gas consumption (m/min) | 0.3(m3/min) |

| Measuring accuracy | ±1% |

| Production capacity | 10-50(a/min) |

| Overall dimensions | 1900×1000×1900mm |

| Net weight (kg) | 280 |

1. The automatic tube filling and sealing machine has a compact structure, automatic tube loading, and a fully enclosed transmission part.

2. The tube is supplied and washed pneumatically, the action is accurate and reliable, the automatic calibration is completed by photoelectric induction, and the adjustment and disassembly are simple;

3. The intelligent temperature control and cooling system makes the operation simple and convenient to adjust. It is equipped with quantity memory and quantitative shutdown device;

4. Automatic tail sealing, which can pass different manipulators on a unified machine to obtain multiple sealing methods such as two-folding, three-folding, and saddle-folding;

5. The material contact part is made of 304 stainless steel, which is clean and hygienic, and fully meets the GMP requirements for pharmaceutical production;

6. Provide safety device, open door and hang, no tube no filling, overload protection.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail