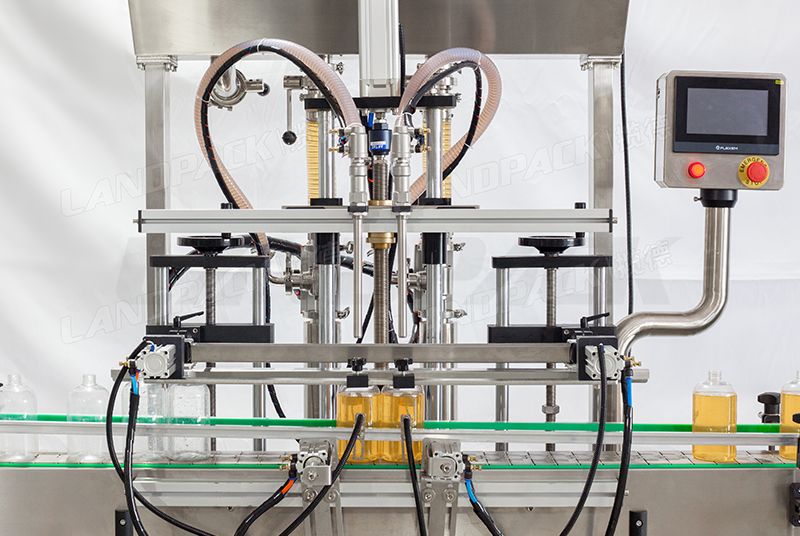

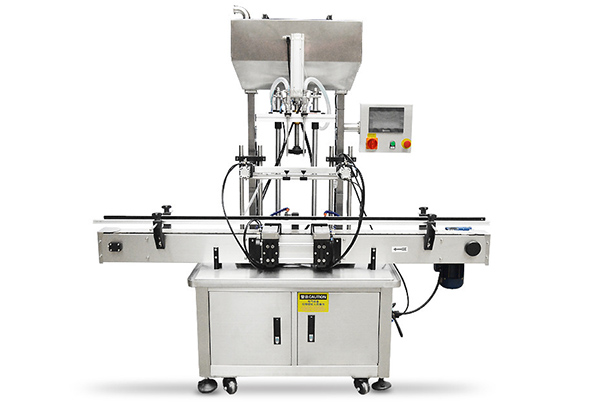

2 Nozzles Double Heads Viscous Filling Machine

Model: LD-GZ021

Application:

Our filling machine is suitable for your production as heavy sauces, salsas, salad dressings, cosmetic creams, heavy shampoo, gels, conditioners, paste cleaners and waxes, adhesives, heavy oils and

lu lubricants.

Advantages:

The machine integrates electric and pneumatic functions into one, with electric heating for the hopper and tube, also assembled with mixing functions. The whole machine is easy cleaning, convenient operation, and conforms to GMP standards.

Application:

Our filling machine is suitable for your production as heavy sauces, salsas, salad dressings, cosmetic creams, heavy shampoo, gels, conditioners, paste cleaners and waxes, adhesives, heavy oils, and lubricants.

Packaging Type: It is suitable for various materials, and various bottle types, and has a wide range of applications.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Model | LD-GZ021 |

Product name | 2-Head filling machine |

Filling volume | 5-150 30-500 60-1000g |

Filling Speed | 20-50 B/min |

Material | Stainless steel 304 & 316L |

Usage | Pharmaceutical, strong corrosive liquid (such as color bleach, 84 liquid, toilet cleaning liquid, bleach liquid, daily chemical, pesticide) |

Function | Piston filling |

Material hopper | 55L |

Suitable bottle size | ≤100mm |

1. Material tank, filling nozzle and the parts access to liquid are made of #304 stainless steel and PVC used in the food industry.

2. Photoelectric sensor: LEUZE in Germany or SICK of Germany.

3. Relay and air switch: Schneider of France.

4. Material pumping: Domestic stainless steel gear pump.

5. Motor frequency converter: AB of the United States, Schneider of France, or Siemens of Germany.

6. Conveyer belt motor: Domestic AC motor.

7. Materials of the seal ring of the sealing machine: silicone, fluorine rubber, polytetrafluoroethylene.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail