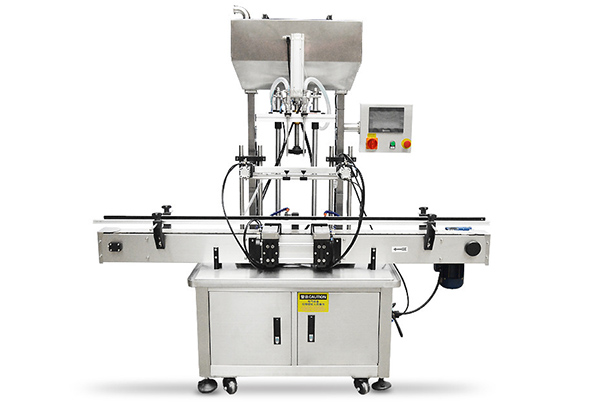

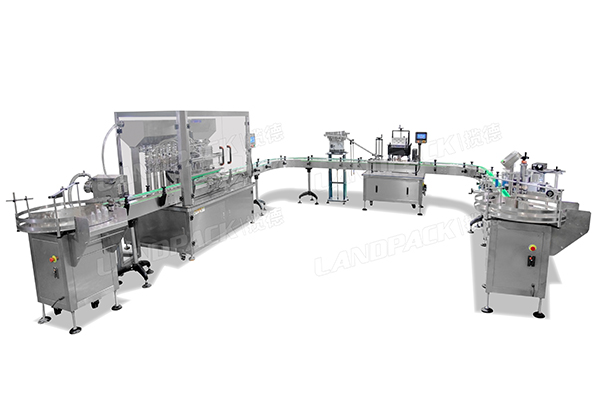

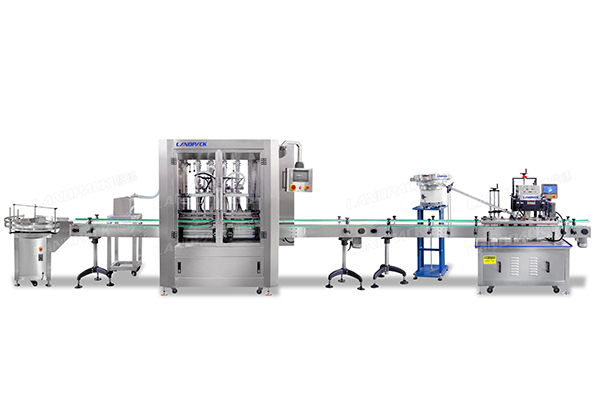

Automatic 10 Heads Piston Pump Soy Sauce Liquid Bottle Filling Capping Labeling Machine

Model: LD-ALF01

Application:

It is suitable for Soy Sauce, Edible Oil, Ghee, Chemical, Cleaning Materials, Agrochemicals, Pesticides, Food and Beverages, Dairy, Juice, pharmaceuticals, Ayurvedic, Nutraceutical, Cosmetic and relevant.

Equipent Charcteristics:

- Fully pneumatic control

- Wide suitability

- High filling accuracy

- Labor-saving

- Easy to use and maintain

Application:

It is suitable for Soy Sauce, Edible Oil, Ghee, Chemical, Cleaning Materials, Agrochemicals, Pesticides, Food and Beverages, Dairy, Juice, pharmaceuticals, Ayurvedic, Nutraceutical, Cosmetic and relevant.

Examples: Such as Soy Sauce, laundry detergent, shampoo, shower gel, hand soap, sauce, lubricating oil, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

| Model | LFZ-06 | LFZ-08 | LFZ-10 | LFZ-12 |

| Filling Range | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) |

| Filling Speed | <30 bottles/min (customizable) | <40 bottles/min (customizable) | <50 bottles/min (customizable) | <60 bottles/min (customizable) |

| Measurement Accuracy | ±1% | ±1% | ±1% | ±1% |

| Power | 1KW | 1.2KW | 1.2KW | 1.5KW |

| Power Supply | 220V,50Hz | 220V,50Hz | 220V,50Hz | 220V,50Hz |

| Working Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa |

| Weight | 400kg | 450kg | 500kg | 550kg |

It is made of electrical components of internationally famous brands.

1. No filling if there is no bottle, no filling if the bottle is falling;

2. Achieve one-click adjustment and can store 40 formulas;

3. Make sure to clean everywhere, particularly those areas out of sight.

4. The submersible filling function can be configured to prevent bubbles during the filling process;

5. The filling accuracy is high, and the vacuum suction device can be configured to achieve equal liquid-level filling;

6. Compared with linear filling, tracking filling is twice as fast.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail