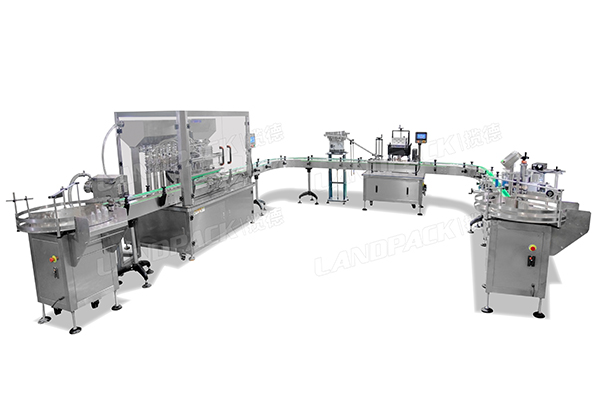

Automatic Glass Bottle Grape Wine Filling Machine

Model: LD-GZX028

Application:

It is suitable for the quantitative filling of various oils such as sunflower oil, shampoo, alcohol, hand sanitizer, beverage, wine, motor oil, lubricating oil, and industrial oil.

Advantage:

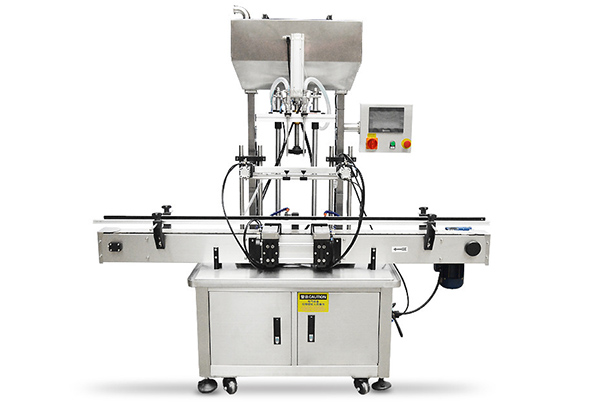

The product adopts advanced general control technology by using a PLC touch screen, and intelligent filling to make operation simpler, more convenient, and easier to study, can set the filling amount and filling speed through the touch screen.

Application:

It is suitable for the quantitative filling of various oils such as sunflower oil, shampoo, alcohol, hand sanitizer, beverage, wine, motor oil, lubricating oil, and industrial oil.

Examples: hand sanitizer, distilled spirits, lubricating oil, edible oil, liquid detergent, shampoo, tomato sauce, salad sauce, etc.

Packaging Material: Glass, Metal, Paper, Plastic, Wood, And Others

Kindly Reminder:

| Bottle Material | PET / PP / PE / Glass / Metal |

| Bottle Shape | Round / Square/ Unique Shape |

| Filling Range | 0.2-1Lor 0.5-5L or 5-25L |

| Filling Heads | 4-12 |

| Production Capacity | 700-4000bph |

| Gas Requirement | 0.6-0.8MPa |

| Filling precision | 3 |

| Working voltage | AC220V/380V 3phase 50/60Hz, 2.2-6.5KW |

| User Ambient Conditions | Temperature:10~40℃; Humidity: No dew |

| Packing size | 1700*1500*2200mm Specific to the actual prevail |

1. The frame of the whole machine is welded with high-quality stainless steel.

2. According to a different output, filling machines with different head numbers can be equipped. Such as 2 heads 4 heads 6 heads 8 heads.

3. The PLC touchscreen operation interface supports multiple languages around the world, you need to inform in advance, the default is Chinese and English interface.

4. The equipment filling valve adopts a unique design and is equipped with a vacuum suction device, which can realize no leakage during the filling process.

6. Long service life and low maintenance cost.

7. Realize filling at different speeds, with fast filling speed and high precision.

8. The host adopts a closed structure to avoid secondary pollution during the filling process.

9. It is suitable for round and various shapes of glass bottles and plastic bottles for oil filling machines.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail