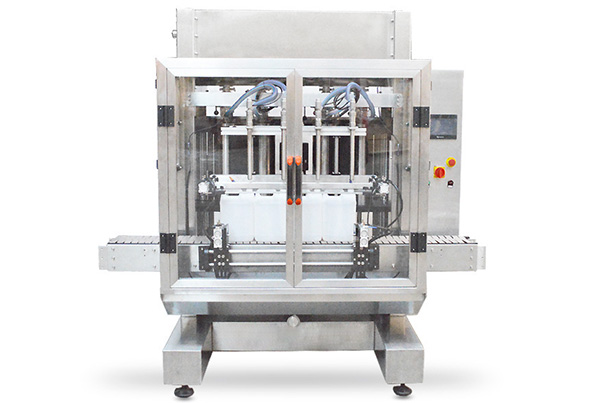

Automatic Liquid Bottle Gravity Type Filling Machine

Model: LF-LZ-04

Application:

It is an economical filling machine that is best suited for liquids with very thin viscosities that do not change with ambient temperature or with a batch variation. such as glass cleaners, Alcohol disinfectants, water, juice, etc in the foodstuff, cosmetic, and daily chemical industries.

Advantages:

This is the most economical type of filling machine for a limited range of applications. It is especially well suited for corrosive chemicals.

Application:

It is an economical filling machine that is best suited for liquids with very thin viscosities that do not change with ambient temperature or with a batch variation. such as glass cleaners, Alcohol disinfectants, water, juice, etc in the foodstuff, cosmetic, and daily chemical industries.

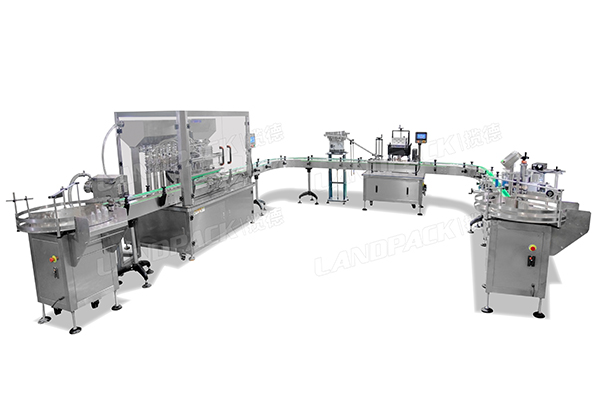

Packaging Type: Barrel, Bottles, Cans, Capsule, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, And Others

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

How It Works:

The product bulk supply is pumped into a holding tank above a set of pneumatically operated valves. Each valve is independently timed by the filler's master computer so that precise amounts of liquid will flow by gravity into the container. Gravity fillers built with bottom-up fill capability can handle a wide range of flowable liquids including foamy products.

Parameter:

| Model | LF-LZ | ||||

| Nozzle Number | PCS | 6 | 8 | 10 | 12 |

| Filling volume | Ml | 100-5000 | |||

| Production capacity | Bottle/h | 1000-3000pcs(Depends on filling volume) | |||

| Quantitative error | % | 100-1000ml:≤±2% , 1000-5000ml:≤±1% | |||

| Voltage | V | AC220V 380V ±10% | |||

| Consumed power | KW | 1.5 | 1.5 | 1.5 | 1.5 |

| Air pressure | MPA | 0.6-0.8Mpa | |||

| Air consumption | M3/min | 0.8 | 1 | 1.2 | 1.2 |

Made of high-quality 304 Stainless steel, it is durable.

316 stainless steel product contact parts are available for optional according to product features.

Flexible machine for filling 100-5000ml.

A liquid receive tray is available in case of any dripping from the filling nozzle.

A diving filling head is available for optional filling foamy liquid.

No bottle no fill.

Controlled by PLC and operated through the touch screen.

Easy change over to different size bottles.

Quick-install connecting parts, it is easy to disassemble and clear the machine.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail