Automatic Liquid Premade Pouch Rotary Filling Machine With Storage Hopper

Model: LD-8200L

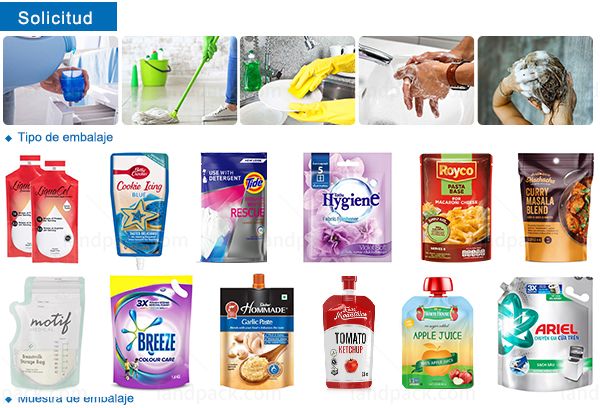

Application:

Suitable for All Kinds of Pre-Made Pouches, and liquid packing, such as honey, fruit juice, laundry detergent, black pepper sauce, beverage, tomato sauce, peanut butter, jam, etc.

Suitable Pouches:

All type of heat sealable preformed side seal bags, fin seal bags, gusseted bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout ect.

Application:

Automatic liquid premade pouch rotary filling machine with storage hopper, it is suitable for filling liquids and pastes of any fluidity in various industries.

Examples:

Honey, fruit juice, laundry detergent, black pepper sauce, beverage, tomato sauce, peanut butter, jam, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

| Model | LD-8200L |

| No.of working stations | Eight |

| Bags size | W: 100-200mm L: 100-400mm |

| Filling range | 10-2500g depending on type of products |

| Packing speed | 25-60bag/min(speed is determined by the product filling quantity) |

| Total power | 2.5KW |

| Weight | 1400kgs |

| Dimensions | 1140mm X 1500mm X 1560mm(L*W*H) |

| Work flow | giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product |

| Main standard parts | 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

1..Easy to operate: PLC and color panel, fault indication on the panel.

2.Easy to adjust: Only about 10 minutes to change different pouches.

3.Frequency control: Speed can be adjusted by frequency conversion within the range.

4.Waterproof design: The machine surface can be washed down, so easy cleaning and has a longer useful life.

5.No pouch/incorrect pouch opening-no fill-no seal, machine alarm.

6.Machine alarm and stop when the inadequate air pressure.

7.Safety guards with safety switches, machine alarms and stops when the safety guards are opened.

8.Hygienic construction, the product contact parts are adopted sus304 stainless steel.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail