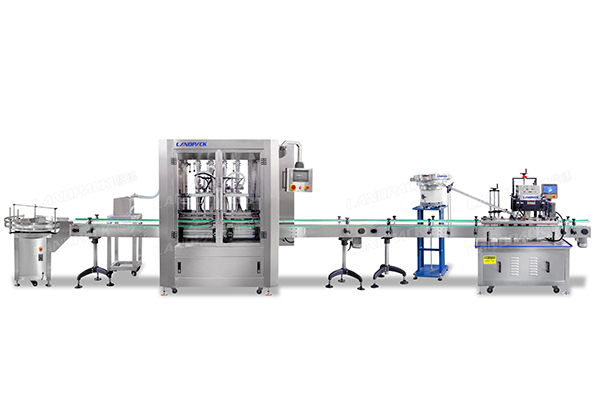

High Precision Single Head Gears Pump Liquid Plastic Bottle Filling Machine

Model: LD-ALF01

Application:

It is used the fill a wide range of water-thin to low-viscosity liquids without gas. Such as juice, soy sauce, vinegar, edible oil, oral liquid, disinfectant, pesticide, chemicals, detergent, lubricating oil, cosmetics, and so on.

Equipent Charcteristics:

- Fully pneumatic control

- Wide suitability

- High filling accuracy

- Labor-saving

- Easy to use and maintain

Application:

It is used the fill a wide range of water-thin to low-viscosity liquids without gas. Such as juice, soy sauce, vinegar, edible oil, oral liquid, disinfectant, pesticide, chemicals, detergents, lubricating oil, cosmetics, and so on.

Examples: Such as Cosmetics, laundry detergent, shampoo, shower gel, hand soap, sauce, lubricating oil, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

| Model | LFZ-06 | LFZ-08 | LFZ-10 | LFZ-12 |

| Filling Range | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) |

| Filling Speed | <30 bottles/min (customizable) | <40 bottles/min (customizable) | <50 bottles/min (customizable) | <60 bottles/min (customizable) |

| Measurement Accuracy | ±1% | ±1% | ±1% | ±1% |

| Power | 1KW | 1.2KW | 1.2KW | 1.5KW |

| Power Supply | 220V,50Hz | 220V,50Hz | 220V,50Hz | 220V,50Hz |

| Working Pressure | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa | 0.6-0.8MPa |

| Weight | 400kg | 450kg | 500kg | 550kg |

It is made of electrical components of internationally famous brands.

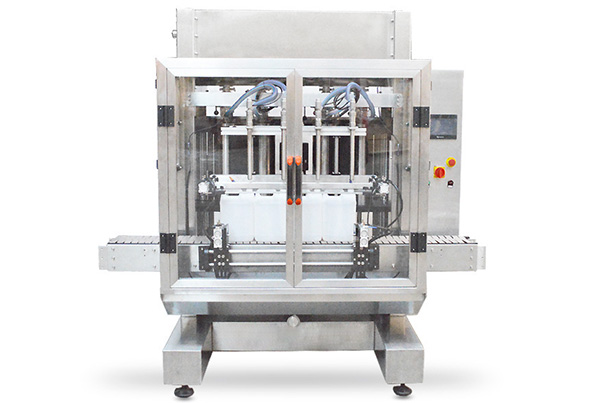

1. Single-head gear pump filling, servo-controlled flow uniformity and high-precision filling, accuracy error 1%.

2. The measuring speed is fast. For example, if 500ml is used, the production speed can reach 7-8 bottles, which is twice that of piston filling.

3. Compatible with common capacity filling of 50ml-5L, no need to change the mold screen to set directly; semi-automatic filling up to 20L.

4. Compatible with most flowable liquids, and can be filled with viscosity below honey (5000).

5.It adopts three-speed filling or two-speed filling, and the three-stage speed and filling volume can be adjusted to prevent the liquid from splashing out after full.

6.Intelligent control, automatic photoelectric tracking, no bottle filling.

7.There is a clamping mechanism at the back end of the machine conveying; it can be connected to the back end for the transition of the back end conveying line.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail