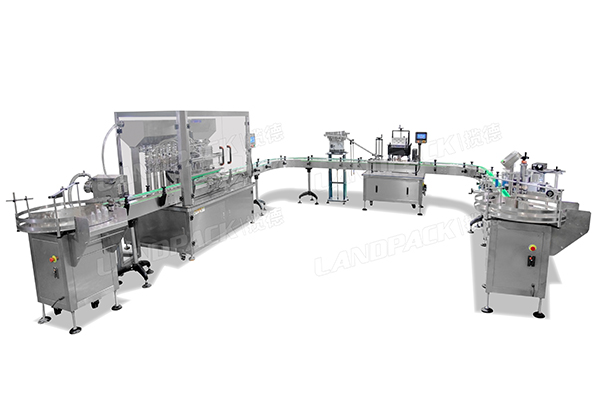

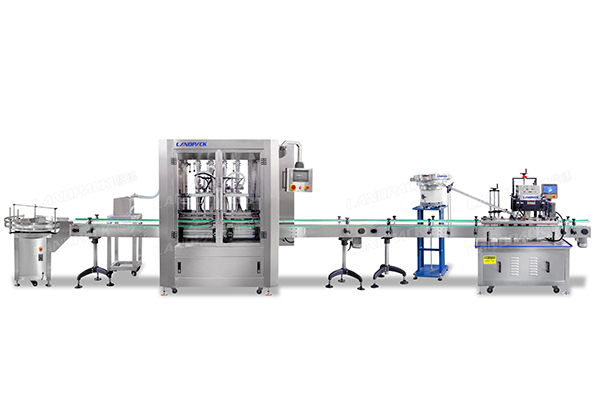

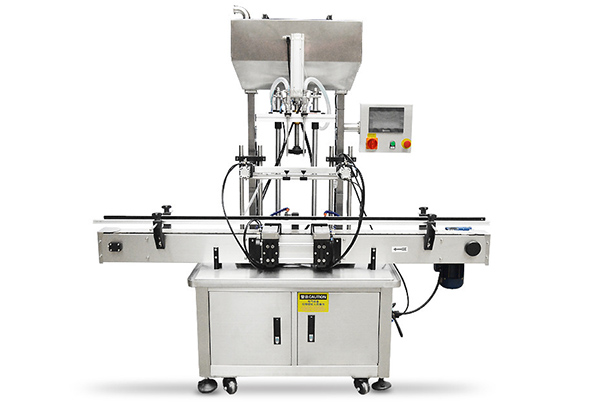

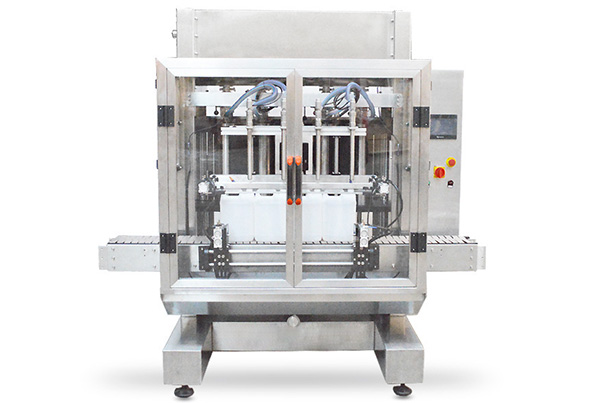

High Speed 10 Nozzles Automatic Liquid Filling Machine

Model: LD-GZ019

Advantages:

1. Schneider touch screen and PLC.

4. Controlled by Panasonic servo motor or cylinder.

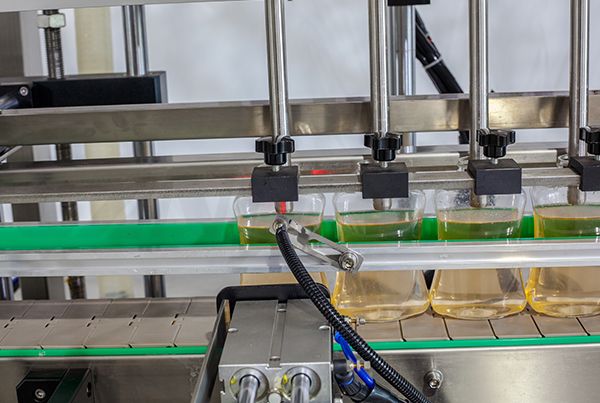

5. The filling-blocked nozzles are anti-drops, silk, and auto-cut viscous liquid.

6. Easy to maintain, no special tools are required.

7. Diving nozzles for bottom-up filling of foaming products if needed.

Application:

It is suitable for Lubricant Oil, Edible Oil, Ghee, Chemical, Cleaning Materials, Agrochemicals, Pesticides, Food and Beverages, Dairy, Juice, Pharmaceutical, Ayurvedic, Nutraceutical, Cosmetic and relevant.

Examples: Such as Cosmetics, laundry detergent, shampoo, shower gel, hand soap, sauce, lubricating oil, drink, etc.

Packaging Material: Glass, Metal, Paper, Plastic, Wood, And Others

Packaging samples:

Speed | 450-1500 bottles/hour | |

Filling range | 100ml-500ml,100ml-1000ml,1000ml-5000ml | |

Measurement precision | ±1% | |

Working power | 220VAC/380VAC | |

Air pressure | 6~8KG/cm² | |

Air consumption | 1m³/min | |

Power rate | 0.8kw | |

Other devices power rate | 6.5kw(air compressor) | |

Net weight | 350Kg | |

1. This machine adopts PLC, touch screen control panel, convenient to adjust.

2. Each filling head has a weight and feedback system, Each filling head can be regulated.

3. Photoelectric sensors, approximate switches, and other electric elements are the internationally famous brand No container no filling. The main host can trigger the alarm if there is any container blocked.

4. Submerged filling makes it possible to reduce forms. It is suitable for various kinds of products.

5. The whole machine meets GMP standards. It is easy to disassemble clean and maintain, and the parts which. cont with filling products made of high-quality stainless steel. The whole machine is safe, environmentally, and sanitary. adapts to various kinds of working places.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail