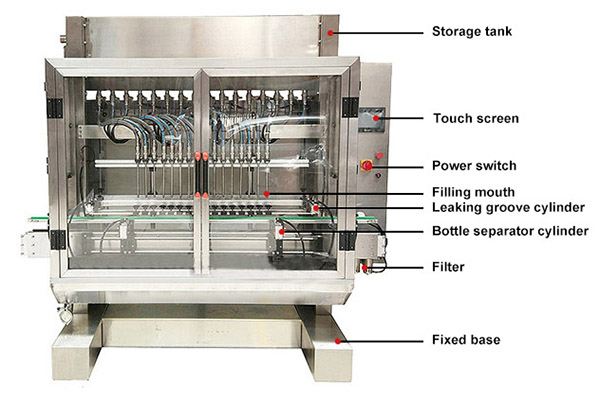

High Speed Gravity Type Liquid Bottle Filling Machine

Model: LF-LZ-08

Application:

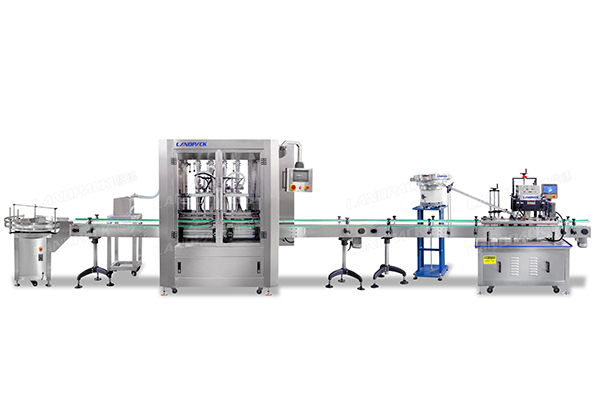

High-Speed Gravity Type Liquid Bottle Filling Machine(LF-LZ-08), It is widely used in the filling of non-viscosity and low-viscosity liquid products in the daily chemical, pesticide, pharmaceutical, wine, beverage, and other industries.

Introduction:

This machine is a high-tech filling equipment that is programmable by a microcomputer (PLC), photoelectric sensor, and pneumatic execution.

Application:

High-Speed Gravity Type Liquid Bottle Filling Machine(LF-LZ-08), It is widely used in the filling of non-viscosity and low-viscosity liquid products in the daily chemical, pesticide, pharmaceutical, wine, beverage, and other industries.

Packing Examples: Non-viscosity or low-viscosity products such as liquor, soy sauce, vinegar, condiments, vegetable oil, syrup, mineral water, etc.

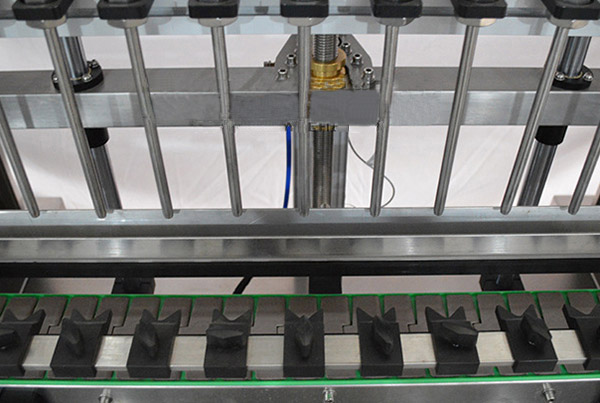

Packaging Type: Suitable for various bottle types of 500-5000ml, Suitable for filling bottles with various shapes, such as square, round, elliptical, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Technical Parameter:

| Model | CGF-NJ8L |

| Filling volume | 25-250ml,50-500ml,100-1000ml,500-2500ml |

| Filling speed | 32-40bottles/min(6 filling heads) |

| Accuracy | <±1% |

| Voltage | 220V 50HZ |

| Air pressure | 4-6MPa |

| Dimension | 2500*900*2000 |

| Weight | 350KG |

(1) Use famous brands of electrical and pneumatic components, low failure rate, reliable performance, and long service life;

(2) The machine frame is made of stainless steel, easy to disassemble and clean, and meets the requirements of GMP;

(3) The adjustment of filling volume and filling speed is simple. Operation by touch screen, the appearance is beautiful;

(4) No bottle, no filling. Control feeding material automatically;

(5) No need to replace parts, you can quickly adjust the various shapes and specifications of the bottle;

(6) The filling head is equipped with a special leakage-proof device;

Note: The range and speed of filling can be designed according to the needs of the user.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail