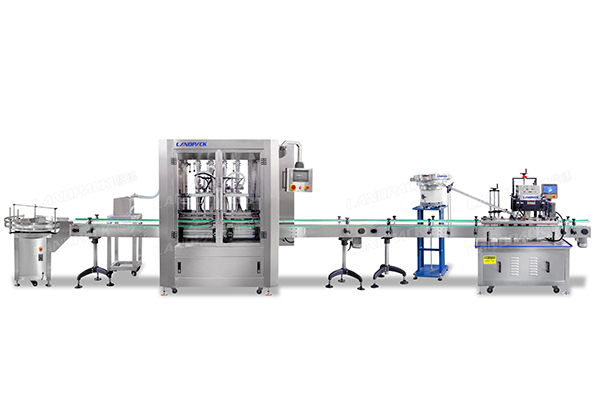

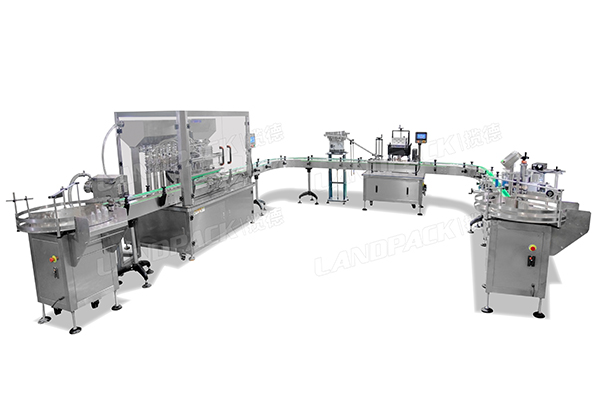

Low Cost Automatic Liquid Bottle Filling Machine

Model: LF-LH-02

Application:

low cost automatic liquid bottle filling machine (LF-LH-02) is widely used for filling various liquids, viscous bodies, pastes, and semi-fluids containing particles, pastes, sauces, etc.

Advantages:

Novel design, beautiful appearance, friendly interface, strong adaptability, simple operation, accurate filling volume, convenient maintenance, etc.

Application:

low cost automatic liquid bottle filling machine (LF-LH-02) is widely used for filling various liquids, viscous bodies, pastes, and semi-fluids containing particles, pastes, sauces, etc.

Examples: Shampoo, honey, laundry liquid, shower gel, lotion, machine oil, soup, detergent solvents, alcohol, specialty chemicals, paint, inks, automobile glass water, sauces, seasonings, etc.

Packaging Type: It is suitable for various materials, and various bottle types, and has a wide range of applications.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Product Description:

The automatic liquid filling machine adopts the quantitative filling principle of the plunger. The bottle feeding, positioning, filling and bottle output are controlled automatically by PLC, conforming to the GMP standard. It is suitable for the liquid filling of medicine, food, daily chemical, pesticide, and the fine chemical industry.

Technical parameter:

| Model | LF-LH-02 |

| Filling volume(ML) | 10-100ml(Can be customized) |

| Filling speed(BPM) | 10-20bottles/min |

| Voltage(VAC) | 220V |

| Power(KW) | 1.0 |

| Air consumption(MIN) | 1KGS×30LITER |

| Dimension | 2000x1000x1800 |

| Weight(KG) | 200 |

1. Touchscreen interface

2. Up and down movement of 8 filling heads, effectively prevents bubbles

3. filling precision up to +1%

4. The filling cylinder is treated by hard chrome and ground, and the unique filling valve is designed without dripping

5. No bottle, no filling

6. Different positioning devices are designed according to the actual situation of the bottle

7. The equipment is easy to clean and can be cleaned online or sterilized at high temperature

8. PLC adopts the Japanese brand Mitsubishi

9. Frequency converter uses France Schneider

10. Pneumatic components uses Taiwan AirTAC

11. The material of the whole machine uses SUS 304# stainless steel

12. Equipped with sanitary and safety standard glass shields

Note: The filling range and speed can be designed according to the user's demand

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail