Application:

Automatic granule can filling line with multihead weigher, it is applicable for different dimension containers, suitable for bottled, canned and tinned foods. such as seafood, nuts, snacks, popcorn, puffed food and so on.

Packaging Type:

cartons, bottles, plastic cans, glass cans, tinplate cans, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Parameter:

| Name | Automatic Granule/ Grain / Solid Filling Line For Bottles Cans And Tins |

| Sealing number | 1 |

| Packing Speed | 50 cans/ min |

| Applicable can Height | 30-200mm (Adjustable) |

| Applicable can diameter | 40-150mm |

| Air sourse | 0.6-0.8MPa |

| Power | 6KW |

| Weight | 2500K |

| Size | 10000mm*3900mm*3000mm |

| Voltage | 380V/220V,50Hz |

Feature:

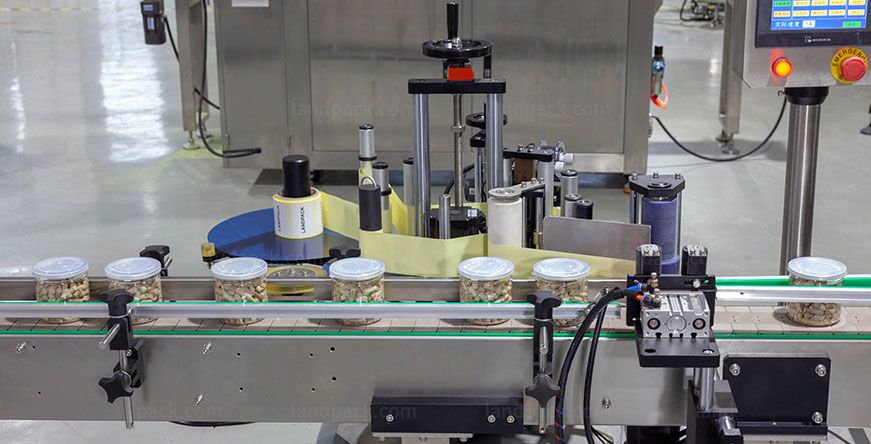

1. Full-automatic weighing-filling-sealing-sterilizing-labeling, efficient and simple to use.

2. Use famous brand electric and pneumatic components, stable and long life circle.

3. Use superior mechanical components, reduce the wear out loss.

4. PLC control and color touch screen 7"with stable and high accuracy output.

Optional supporting devices:

1. bottle unscrambler;

2. multihead weigher scale;

3. Z-type lifting feeder;

4. granule filling machine;

5. sealing machine;

6. capping machine;

7. labeling machine;

8. aluminum foil sealing machine, etc.

Get Price & More Detail