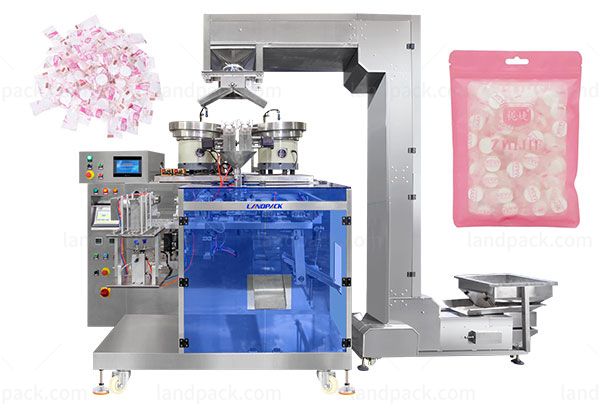

Automatic Premade Bag Candy Rotary Doypack Packing Machine

Model: LD-8200A

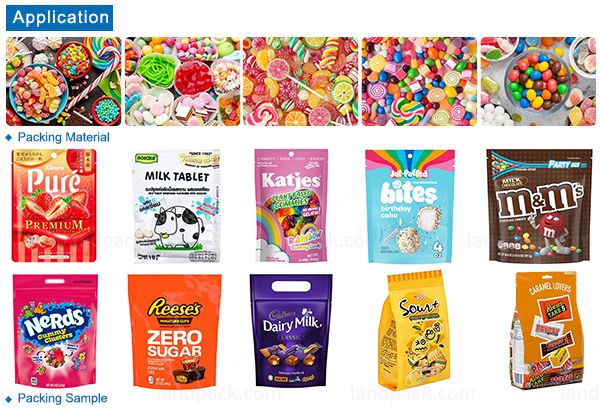

Application:

Suitable for various granlue material in premade pouch style, such as candy, nut, cashew, candy, beans, chips, popcorn, pasta, corn, jelly, cookies, cheese, peanuts, coffee bean, almond, pet food, etc.

Advantage:

It also has a good seal to ensure the safety and hygiene of the packaging.

Application:

Automatic premade bag candy doypack packing machine, it can flexibly adapt to bags of various specifications for packaging to improve production efficiency.

Examples:

candy, dry fruit, nut, cashew, candy, beans, chips, popcorn, pasta, corn, jelly, cookies, cheese, peanuts, coffee bean, almond, pet food, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

| Model | LD-8200A |

| Name | Automatic Coffee Beans Nitrogen-Filled Filling Packing machine |

| Sealing number | 8 |

| Packing Speed | 40 cans/ min |

| Applicable can Height | 30-200mm (Adjustable) |

| Applicable can diameter | 40-150mm (Adjustable) |

| Air sourse | 0.6-0.8MPa |

| Power | 2.5KW |

| Weight | 2500K |

| Size | 10000mm*3900mm*3000mm |

| Voltage | 380V/220V,50Hz |

1.The section where the material contact is stainless steel as the body of machine is optional for complete or partial stainless steel and all out equipments have passed the CE Standard.

2.Computer controller is the first patent of China; inverter and power switch are all imported with advanced technology.

3.High-sensitivity photoelectric color tracing and digital input of cutting position get more accuracy.

4.Embedded sealing ,enhanced structure of heat sealing intelligent temperature controller and excellent heat balance make all kinds of packaging

5.Equipped with rolled cup device enables volume of packing changing anytime, loss reducing and improve productivity.

6.Alarming function for specific output; automatic display of packaging speed.

7.Optional coding equipment and with 1 to 3 lines for batch number and expiration date.

8.Bag-making, filling, sealing, cutting, counting, thermal pressing of batch number can be achieved automatically and straightly.

9.Flat cutting, pattern cutting, linking cutting can be realized by changing the tools;easy operation with smooth bags.

10.Bag-making equipment can be changed according to specific requirement of customers and products.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail