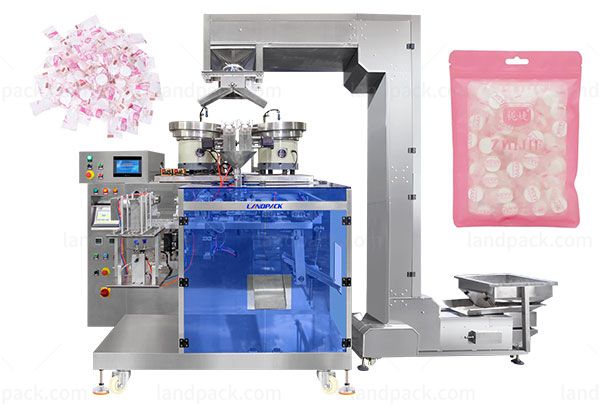

Automatic Granule Snacks Candy Premade Pouch Counting Packing Machine

Model : GP-160A

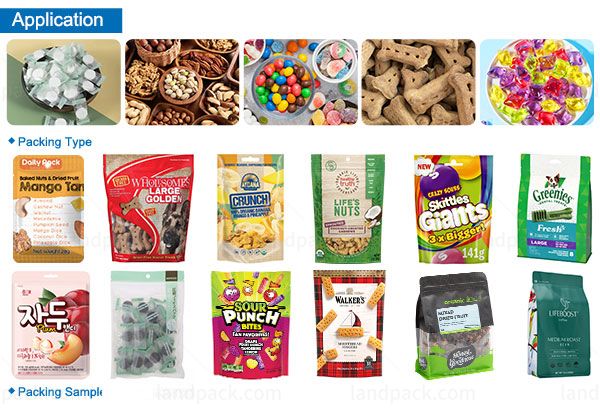

Application :

This versatile counting and packing machine is ideal for a wide range of products, including candy, pet food, nuts, candy, chips, puffy food, pistachios, jelly, rice, coffee beans, frozen dumplings, pasta, cotton candy, apple slices, french fries, small hardware, and more.

Application :

This versatile counting and packing machine is ideal for a wide range of products, this versatile machine ensures efficient and precise packaging for diverse applications.

Examples :

Candy, pet food, nuts, candy, chips, puffy food, pistachios, jelly, rice, coffee beans, frozen dumplings, pasta, cotton candy, apple slices, french fries, small hardware, and more.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4-side sealing bag, Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag, etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

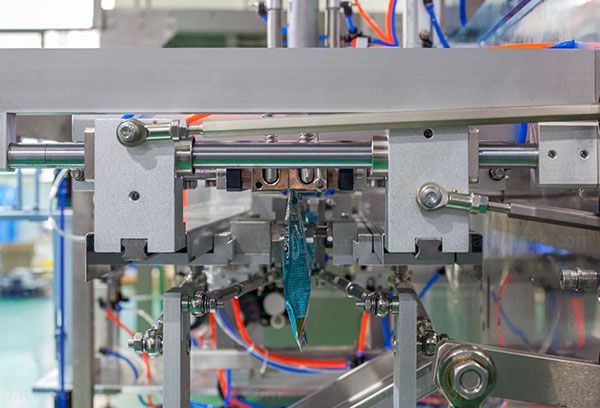

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | |||

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | |

| Collocation | Screw metering, screw elevator | |||

1. User-Friendly Interface: Equipped with a 7-inch Siemens touchscreen offering a multi-language interface, making it easy to adjust settings and ensuring straightforward operation.

2. Precise Dosing: Utilizes cutting-edge Japanese multi-head weigher technology for highly accurate and consistent product weighing.

3. Complete Automation: This machine handles all stages of packaging, from feeding and dosing to bagging and sealing. It supports various bag types, including stand-up, Euro hole, linked, and bags with printed dates.

4. Wide Bag Compatibility: Compatible with a range of packaging materials such as laminated pouches, PE, aluminum, and paper bags. It also supports multiple bag styles, including 3-side and 4-side seal bags, zipper bags, stand-up bags, pillow bags, and handle bags with punched holes.

5. Broad Industry Use: Ideal for both food and non-food industries, offering a flexible and efficient packaging solution for a wide range of products.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail