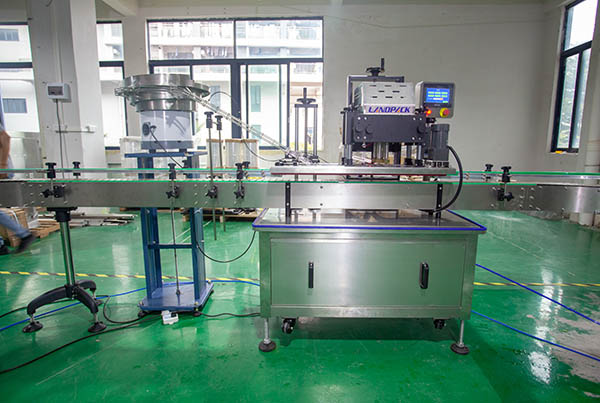

Automatic 4 Wheels Capping Machine

Model: LFX-JX-00

Application:

Automatic 4 Wheels Capping Machine(LFX-JX-00), it is suitable for various bottles and jars in food, medical, daily chemical and other industries.

Applicable Lids Types:

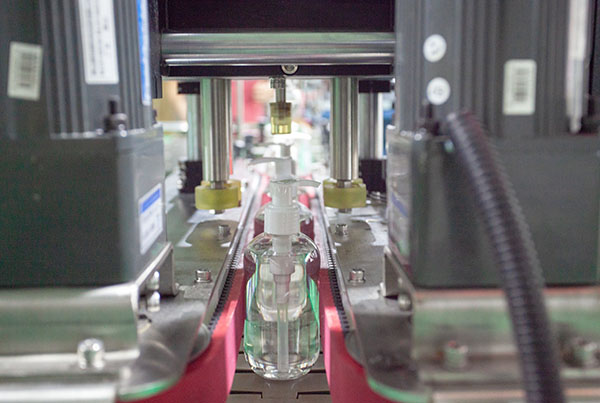

Plastic threaded caps; metal threaded caps; duckbill caps; pump head caps; sprinkler caps and other threaded caps.

Application:

Automatic 4 Wheels Capping Machine(LFX-JX-00), it is suitable for various bottles and jars in food, medical, daily chemical and other industries.

Applicable Lids Types:

Plastic threaded caps; metal threaded caps; duckbill caps; pump head caps; sprinkler caps and other threaded caps.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Brief Introduction:

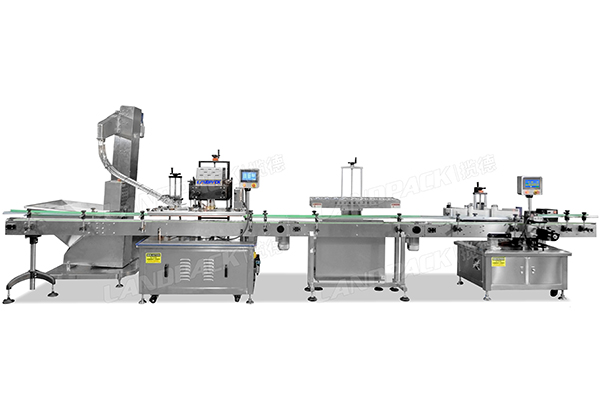

The capping machine is developed by our company based on the introduction of foreign advanced capping principle and technology, combined with many years of production experience. It integrates automatic bottle feeding, automatic cap sorting, automatic capping, automatic capping, and automatic bottle discharging. The whole machine has a reasonable design, compact structure, high work efficiency, stable and reliable operation, simple operation, and can be applied to products of different specifications. Screw cap. The structure is compact and reasonable, and can be combined with other equipment to form a production line.

Parameters:

| Model | LFX-JX-00 |

| Cap Diameter | Φ22mm-Φ70mm (customizable) |

| Bottle Diameter | Φ35mm-Φ140mm (customizable) |

| Bottle Height | 38mm-200mm (customizable) |

| Production Speed | 20-30 Bottles/min |

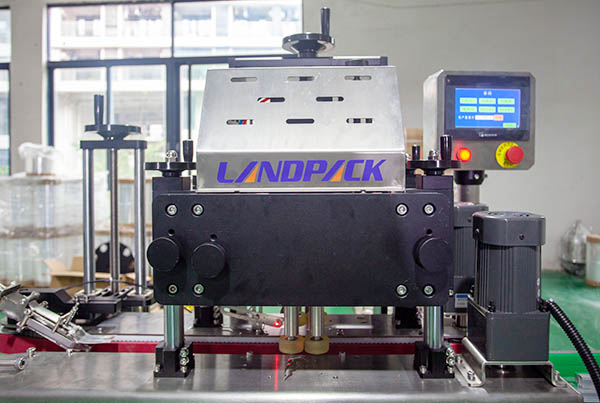

| Control system | PLC |

| Total production line power | 1.5KW |

| Power supply | 220V、50Hz |

| Airconsumption | 0.2-0.4m³/min |

| Equipment Material | 304 |

1. This machine adopts conveyor belt for automatic bottle feeding, automatic capping, capping, belt clamp bottle conveying mechanism, screw cap mechanism, electric control system, etc., with high degree of automation, reasonable design, compact structure and convenient operation;

2. The frame, parts and casing are mainly made of high-quality stainless steel, beautiful in appearance, easy to clean, and meet GMP requirements;

3. Adopting the principle of four-wheel clamping spinning, the structure is simple and reasonable, the performance is stable and reliable, and the work efficiency is high. It solves the drawbacks of traditional capping machines such as slipping and damage.

4. It is suitable for a wide range of applications such as screw caps, anti-theft caps, children's caps, duckbill caps, pump head caps, sprinkler caps, etc.;

5. The spacing and height of the capping mechanism can be adjusted quickly. When changing bottle types and caps of different specifications, the whole process can be adjusted without using tools, and the replacement can be completed by adjusting the handwheel.

6. The cover feed mechanism is equipped with a photoelectric sensor safety protection device, which improves the stability and reliability of the equipment.

We have many customer case videos, please feel free to contact us to obtain your product case videos.

Get Price & More Detail