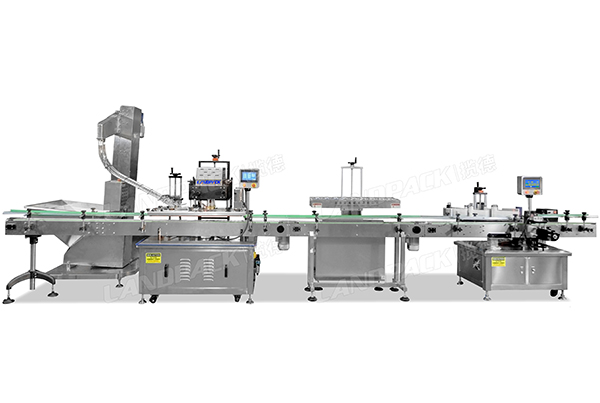

Automatic Capping Aluminum Foll Sealing Labeling Lines

Model: LF-SC-XT

Application:

suitable for bottles in food, medical, daily chemical and other industries. It can complete the processes of screw capping, aluminum foil sealing and labeling.

Description Of The Main Process:

lifting capping machine → four-wheel capping → aluminum foil sealing machine → labeling → bottle collection

Application:

Suitable for products in food, medical, daily chemical and other industries that require a series of processes such as capping, aluminum foil sealing and labeling.

Bottle Type: PET plastic bottles, glass bottles, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Brief Introduction:

This automatic production line can be used in liquid, powder, granule, various food, cosmetics and other industries. Each equipment of this line has reasonable design, compact structure, small floor space, high working efficiency, stable and reliable operation, and simple and convenient operation. The front end can be connected with liquid filling machine, granular filling machine, powder filling machine, and the back end can be equipped with unpacking machine, cartoning machine, sealing machine, and packing machine to form a fully automated production line. Save labor and have a high degree of automation.

Parameters:

| Model | LF-SC-XT |

| Production Speed | 20-30 Bottles/min |

| Control system | PLC |

| Total Production Line Power | 8.5KW |

| Power supply | 220V、50Hz |

| Airconsumption | 0.2m³/min |

| Equipment Material | 304 |

| Description Of The Main Process | lifting capping machine → four-wheel capping → aluminum foil sealing machine → labeling → bottle collection |

| Optional Supporting Devices | liquid filling machine; granule filling machine; powder filling machine; unpacking machine; packing machine; sealing machine, etc. |

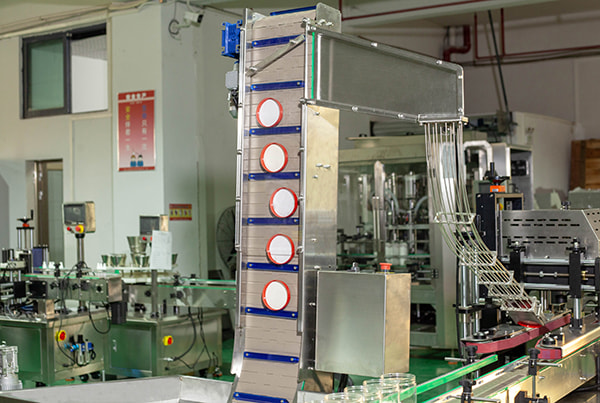

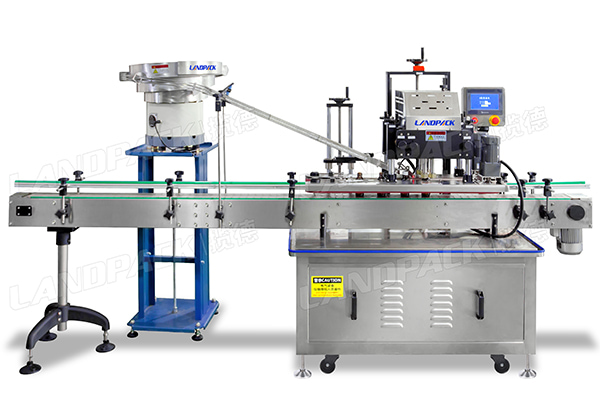

1. This production line adopts lifting type automatic cover, fast cover speed, stable operation, low noise and wide application range;

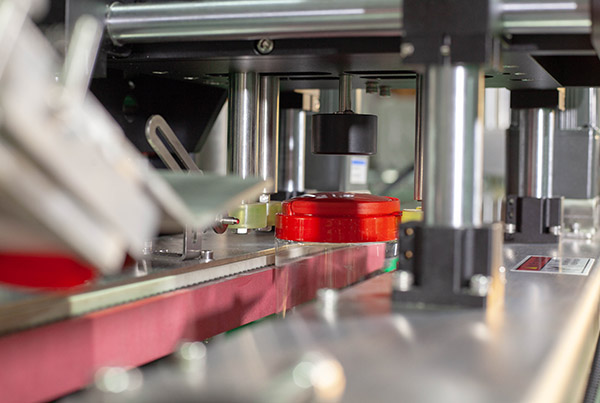

2. Adopting four-wheel capping machine, the structure is simple and reasonable, the performance is stable and reliable, and the work efficiency is high. It solves the drawbacks of the traditional capping machine from slipping and damage to the cap;

3. It is suitable for screw caps, anti-theft and child-proof caps, and has advantages over duckbill caps, pump head caps, and nozzle caps;

4. The spacing and height of the cap screwing mechanism can be adjusted quickly. When changing bottle types and caps of different specifications, it can be adjusted without tools in the whole process, and only need to adjust the hand wheel to complete the replacement;

5. The aluminum foil sealing speed is fast, the sealing quality is good, and the effect is beautiful. The sealing head adopts the handwheel type lifting adjustment, which is easy to use;

6. This line uses a clip-on positioning round bottle labeling machine. The biggest feature of this machine is the use of rollers to rub the label, high precision and high speed;

7. The labeling machine solves the labeling errors caused by the previous belt-type rubbing labels up and down. The machine structure is simple, compact, and easy to operate and maintain;

8. The whole line adopts imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

9. The production line has stable operation, low noise, convenient maintenance, and fully meets GMP certification requirements, and is widely used in medicine, food, cosmetics and other industries;

We have many customer case videos, please feel free to contact us to obtain your product case videos.

Get Price & More Detail