Automatic Coffee Beans Nitrogen-Filled Filling and Lebeling Line

Model: LF-GA-006

Application:

Automatic Coffee Beans Nitrogen-Filled Filling and Lebeling Line(LF-GA-006), It is suitable for bottling, filling and tinplate canning of various coffee beans. Different ways to extend the shelf life can be selected according to the characteristics of the coffee beans, such as Inert gas packaging, No pressure air packaging, Pressurized packaging etc.

Filling Line Composition:

bottle sorting machine → canning system → can sealing machine → liquid nitrogen drip machine → full automatic inkjet printer

Application:

Automatic Coffee Beans Nitrogen-Filled Filling and Lebeling Line(LF-GA-006), It is suitable for bottling, filling and tinplate canning of various coffee beans. Different ways to extend the shelf life can be selected according to the characteristics of the coffee beans, such as Inert gas packaging, No pressure air packaging, Pressurized packaging etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

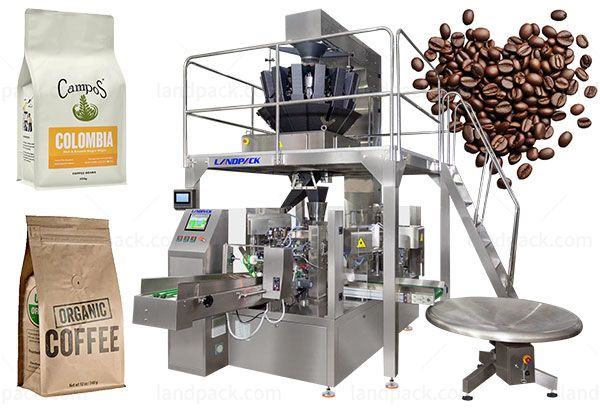

Packaging Samples:

| Model | LF-GA-006 |

| Name | Automatic Coffee Beans Nitrogen-Filled Filling and Lebeling Line |

| Sealing number | 1 |

| Packing Speed | 50 cans/ min |

| Applicable can Height | 30-200mm (Adjustable) |

| Applicable can diameter | 40-150mm |

| Air sourse | 0.6-0.8MPa |

| Power | 6KW |

| Weight | 2500K |

| Size | 10000mm*3900mm*3000mm |

| Voltage | 380V/220V,50Hz |

1. Inert gas packaging

It means that the inert gas replaces the container air, and the inert gas is added through the vacuum compensation technology. The container is vacuumed after filling the coffee beans, and then inert gas is injected to balance the pressure difference in the tank. After exhausting the air in the tank, fill it with nitrogen. Nitrogen is an inert gas and will not oxidize with the acidic fats and volatile fats contained in the coffee beans. It will last for a long time! Vacuuming and filling nitrogen is 3 times longer than general vacuum packaging only!

2. No pressure air packaging

This kind of packaging can simply isolate the influence of moisture, flavor loss and light on the coffee beans. The air in the tank will not continue to oxidize after oxidation. It can reduce the degree of oxidation and extend the shelf life of the coffee beans. Air-cooled coffee beans are generally suitable.

3. Pressurized packaging

The process is similar to vacuum-filled nitrogen packaging. Liquid nitrogen is dripped before sealing, and the temperature of liquid nitrogen at -190°C is raised to room temperature. The gasification volume expands by 696 times to drive off the air. The pressure difference in the tank can delay the coffee beans. "Mature" and deoxidize to prevent the coffee beans from oxidizing, greatly extending the shelf life.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail