Automatic Roasted Coffee Bean Premade Mini Doypack Packing Machine

Model : LDB-430AS

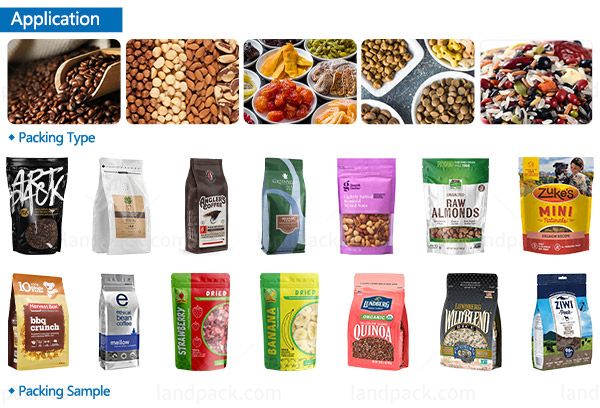

Application :

It can effectively package various solid items such as coffee bean, roasted, rusk, beef jerky, nuts, seeds, dried fruits, snack mixes, candy, granola, popcorn, pet treats, and more, making it an ideal solution for diverse applications in the food industry.

Application :

This machine is perfectly suited for the automatic packaging of solid foods, catering specifically to the coffee bean industry, including specialty, roasted, and green coffee beans.

Examples :

Coffee bean, roasted, rusk, beef jerky, nuts, seeds, dried fruits, snack mixes, candy, granola, popcorn, pet treats, and more, making it an ideal solution for diverse applications in the food industry.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

| Model | LDB-430AS |

| Bag Material | Multilayer Composite Premade Bag (e.g.: PET/PE) |

| Bag Type | 3 Side Seal Bag, stand-up Bag |

| Upgradable Bag Type | Gusset Bag, Zipper Bag, Flat Bottom Pouch (Need additional purchase of functional device) |

| Size Range | 80mm≤W≤300mm, 100mm≤L≤300mm |

| Speed | 0-15 bags/min |

| Sealing Type | Straight grain, the pitch is 1mm (Optional reticulate) |

| Sealing width | 10mm (5-20mm can be customized) |

| Voltage | 220V, Single-phase, 50/60HZ, 1.2KW |

| Air Pressure | 0.65 Mpa |

| Air Consumption | 0.3m³/min (Standard machine, no additional function) |

| Body Dimension | 1770*600*1260mm |

| Packing Dimension | 1860*710*1650mm (Export non-fumigation wooden case) |

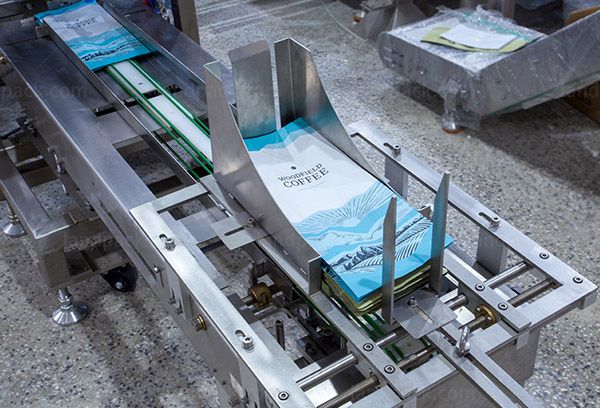

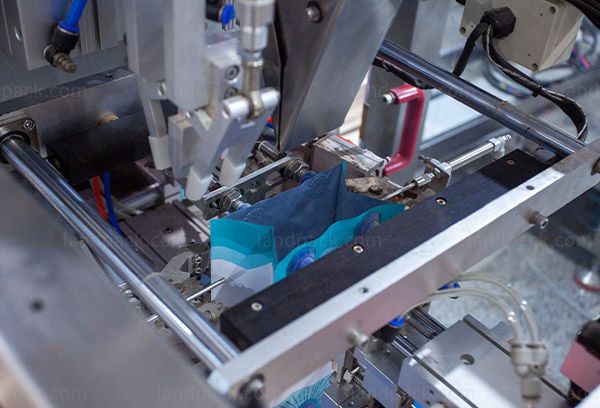

1. Custom Design for Coffee Gusset Pouches: Specifically engineered to efficiently handle gusseted coffee pouch bags, optimizing the packaging process for coffee products.

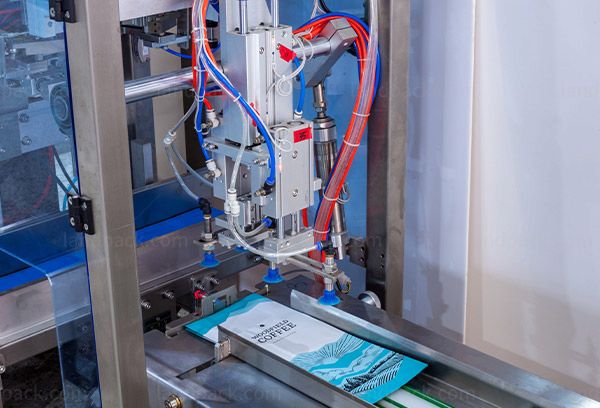

2. Accurate Linear Electric Weighing System: Equipped with linear electric scales that provide stable and precise weighing and filling of coffee, ensuring uniformity in every package.

3. Integrated Printing Solutions: Seamlessly compatible with inkjet coding printers, enabling real-time printing of codes and labels for effective product tracking and quality assurance.

4. User-Friendly Interface: Features an intuitive control panel that simplifies operation and allows for easy adjustments, enhancing user experience and efficiency.

5. Quick Changeover Capability: Designed for rapid adjustments between different pouch sizes and types, minimizing downtime and increasing productivity during production runs.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail