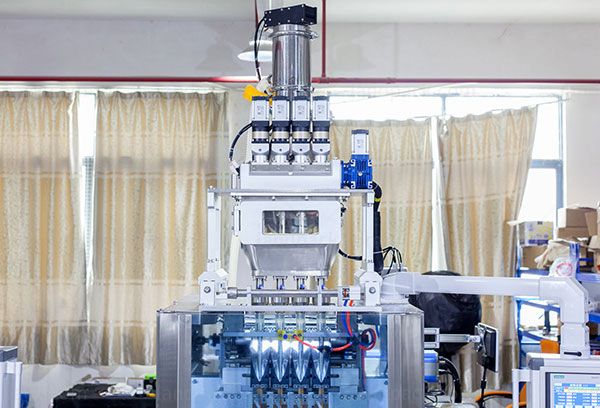

Multi Lane 3 in 1 Coffee Powder Nutrition Powder Stick Packing Machine

Model: LDBK-280D-4

Application:

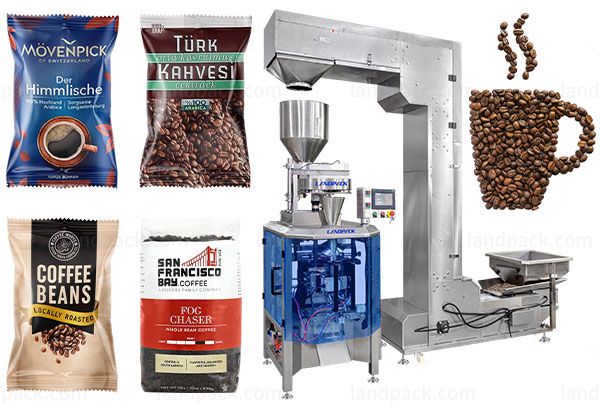

This multilane stick packing machine, it is suitable for many kinds of powder products, such as 3 in 1 coffee powder, chili powder, seed powder, milk tea powder, pharmaceutical powder, herb powder, dry powder, vibro cinnamon powder, flour, milk powder, glucose, medical powder, nutrition powder, etc.

Application:

This multilane stick packing machine, it is suitable for many kinds of powder products, such as 3 in 1 coffee powder, chili powder, seed powder, milk tea powder, pharmaceutical powder, herb powder, dry powder, vibro cinnamon powder, flour, milk powder, glucose, medical powder, nutrition powder, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

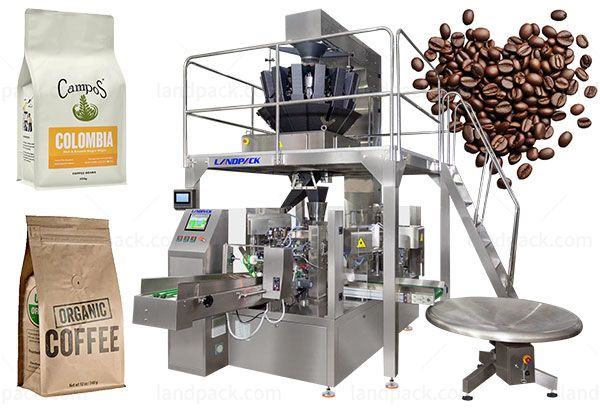

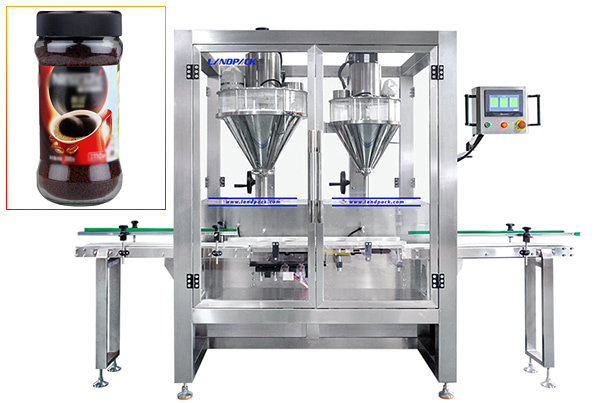

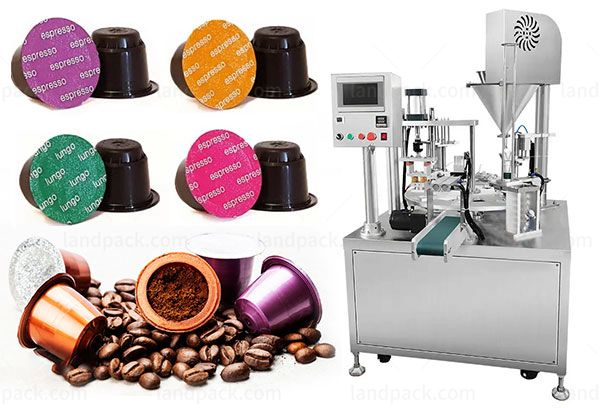

Packaging Samples:

| Model | LD-280BF | LD-560BF |

| Lane number | 4-6 Line | 8-12 Line |

| Filling Method | 1.Volumetric cup; 2. Weigher | |

| Capacity | Max.35 cycle/ min | |

| Sachat Size | L:50-180mm; W:17-30mm | L:50-180mm; W:17-30mm |

| Film weidth & Thickness | Max.280mm, 0.07-0.10mm | Max.560mm, 0.07-0.10mm |

| Sealing type | Back sealing/Stick bag | Back sealing/Stick bag |

| Cutting type | 1.Straight cutting; 2.Zig zag cutting; 3.Round cutting; 4.Irregular | |

| Air & Powder | 0.8Mpa 0.8m3/min; 3.5kw | 0.8Mpa 0.8m3/min; 5.5kw |

| Dimension & weight | 1385*918*2005mm;350kg | 1685*1300*2005mm;550kg |

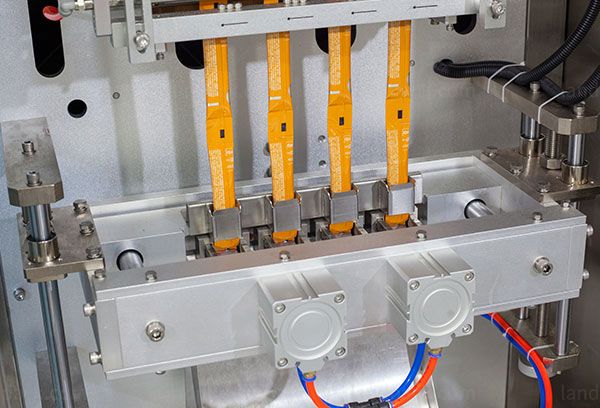

1. Sealing the bags well without any waste film, because of multiple rolls to pull the film for running smoothly, the cutter made of high hard stainless steel, it seal the bag with clear texture , no film stick on the sealing device.

2. The fillet bag is with the easy to tear mark place, so the customers open the bag easier and convenient.

3. Low maintenance cost : The machine is controlled by the timing belt , Independent temperature control table for each heating pipes, which easy to find and solve the problem.

4.Powder vacuum feeding machine to transport the powder from the storage hopper to the measurement device automatically.

5.The machine would pull the flim, print the code by laser , form the bag, measure and fill the powder into bag, sealing and output the finished products automatically. No need worker to operate such function, durning the machine working.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail