Full Automatic Rotary Vacuum Packaging Machine For Dry Food/ Dry Fruit

Model: LDZK240

Application:

It is suitable for high speed vacuum pouch packing of dry food, dry fruit, coffe bean, peanuts, jerky, fish, poultry, meat, grains and other food items.

Advantage:

The vacuum process at the end makes 99.9% vacuum inside the pouch.

Application:

Full automatic rotary vacuum packaging machine(LDZK-240) for dry food/ dry fruit, it is suitable for high speed vacuum pouch packaging.

Examples:

dry food, dry fruit, coffe bean, peanuts, jerky, fish, poultry, meat, grains and other food items.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

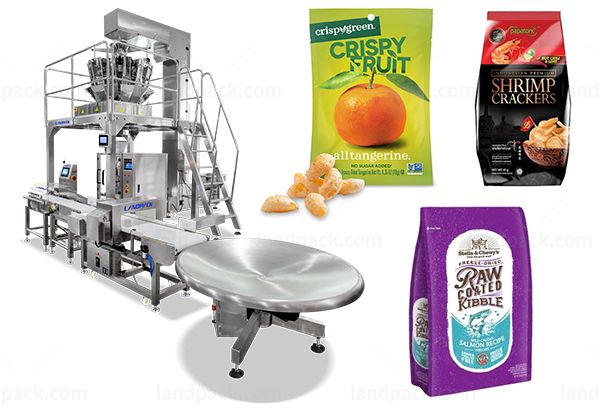

packaging Examples:

| The Main Technical Parameters | |

| Model | LD-8200V |

| Bag Size | Width:70-120mm/120-200mm, Length:80-160mm/150-300mm |

| Filling Volume | 10-500g (Depending on type of products) |

| Capacity | 30-100bags/min (The speed depends on type of products and packaging material used)The highest can be 100 packs / minuteZipper Bag The heghest can be 40packs/minute |

| Package Accuracy | Error≤±1% |

| Total Power | 2.5KW/5.5kw (220V/380V,3PH,50HZ) |

| Demension | 2100*1400*1700 mm/2600*1900*1700(Length*Width*Height) |

| Weight | 1600KGS/3000kgs |

| Compress Air Requirement | ≥0.8m³/min supply by user |

| Pouch Type | All type of heat sealable performed side seal bags, block bottom bags, zip-lock recloseable bags, stand-up pouch with or without spout,Portable bag, zipper bag, hand luggage, edging bag 4 sides, edging bag 3 sides, paper bagetc. |

| Application Product | 1. Any product that can pack in bag, such as fish, poultry, meat, grains and other food items.2. Solid species: candy, peanut, green bean, pistachio, crystal candy, brown sugar, cookie, cake, daily commodities, cooked food, pickles, puffed food, etc.3. Granule species: grain, refined monosodium glutamate, granular drug, capsule, seed, condiment, granulated sugar, chicken essence, melon seeds, nuts, pesticide, fertilizer, feed etc.4. Liquid species: detergent, fruit juice, miller wine, soy sauce, vinegar, drinks etc.5. Thick liquid species: chilli sauce, tomato sauce, peanut butter, jam, bean sauce etc. |

| Work Process | Station 1 Giving Bag Feed many pouches or bags in the bag magazine, our main bag magazine can move up and down, you can feed bags very easily when it moved down, and when it moved up, there are a mechanical arm with two vacuum caps will take bag up and then transmit it to the mechanical gripper on the rotary table.Station 2 Date Printing (option)Station 3 Opening BagTo open stand (flat) pouches from top and bottom with two sets vacuum caps.Station 4 Filling and consolidate 1Measured its weight or volume by scales.There are an opening detection device insertinto the open bagor pouch to expanding it and detect if it is open or not.Station 5 Filling and consolidate 2(Option)Station 6 Bufferingto make bag more straight and to prevent material out from bagStation7 Vacuum and sealingto transform to vacuum equipmentStation 8 Forming and OutputThese 8 stations can change its working function as customized design |

Bag Types:

These machines can work with pre-made bags of the following types:

Stand-up pouches or Doypack pouches with or without zippers

3-side sealed pouches with or without zippers

4-side sealed pouches with or without zippers

Filler Options

1.Volumetric Cup Fillers

2.Multi-head Weigher

3.Counting Fillers

4.Vibrating Fillers

5.Customized filler for fish, poultry, and other meat items

Machine Options

Hole punch device

Gas flush device

Middle capping device

Zipper opening device

Vertical bag loading system

Horizontal bag loading system

Inline check weigher

Dimple plated contact parts for sticky products

Teflon plated contact parts for highly sticky products

Metal detector at output conveyor

Date code printer

Industrial inkjet printer

Laser coder etc. is among many options available.

Build Material Options

SS304 stainless steel based product contact parts for general food/cosmetics/pharmaceutical industries

SS316 corrosion-resistant stainless steel-based product contact parts for highly corrosive products like salt, chemicals, etc.

Optional Related Equipment

1.Raw Material Handling Equipment: Belt Conveyors, Bag Splitting Machines, Large Bag Splitting machine directly from pallets

2.Industrial Powder and Grain Mixers: Ribbon Mixers, Paddle Mixers, Plow Mixers Open Type Mixers

3.Powder Screw Conveying Equipment: Screw Conveyor, Belt Conveyor, Bucket Conveyor etc.

4.Cartoning & Boxing Machines

5.Box Shrink Wrapping Machines

6.Palletizing Robots: Cartesian Robots, Six-Axis Robots

7.In-line Pallet Stretch Wrapping and Labeling Machine

8.Possibility of machine integration with ERP system. (SAP, Microsoft Dynamics, and other ERP software)

9.SCADA integration

10.Agitator/mixer for liquid or paste products

11.Product counter and stacking belt conveyor

12.Rotary table for the convenient collection of the finished products

13.Extra filler equipment for different powder, granular, liquid, or part type products packaging in a single machine. The choices are: volumetric cup filler, 2-head/4-head linear weigher, piston pump filler, auger filler, tablet counting filler, and vibrating filler

14.Air compressor

Standards

In accordance with CE Standards

Optional accordance with OSHA accredited NRTL Certification for USA and CSA for Canada

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail