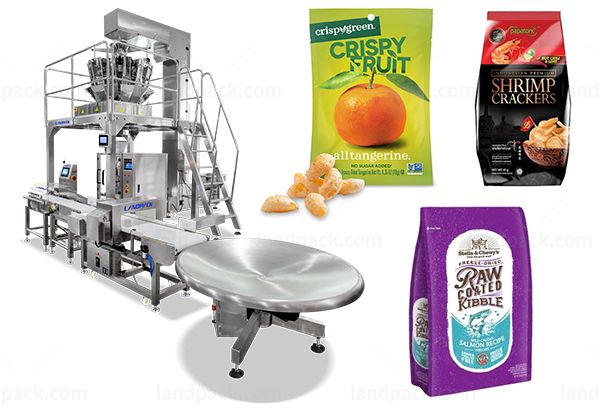

Full Automatic Dry Food Egg Rolls Premade Bag Doypack Packing Machine

Model : LDSP210

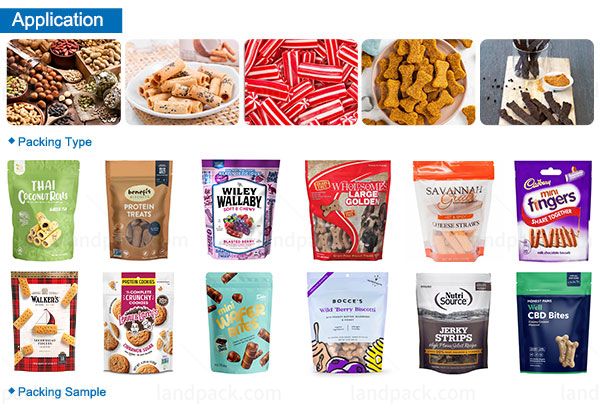

Application :

Ideal for packaging premade stand-up pouches, this machine is perfect for a wide range of granular products, such as mixed nuts, chips, biscuits, egg rolls, candies, snacks, popcorn, trail mix, granola, seeds, dried fruits, and more. It ensures efficient, precise, and high-quality packaging for a variety of food and snack industries.

Application :

Ideal for packaging premade stand-up pouches, this machine is perfect for a wide range of granular products, it ensures efficient, precise, and high-quality packaging for a variety of food and snack industries.

Examples :

Dry food, egg Rolls, mixed nuts, chips, biscuits, egg rolls, candies, snacks, popcorn, trail mix, granola, seeds, dried fruits, and more.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

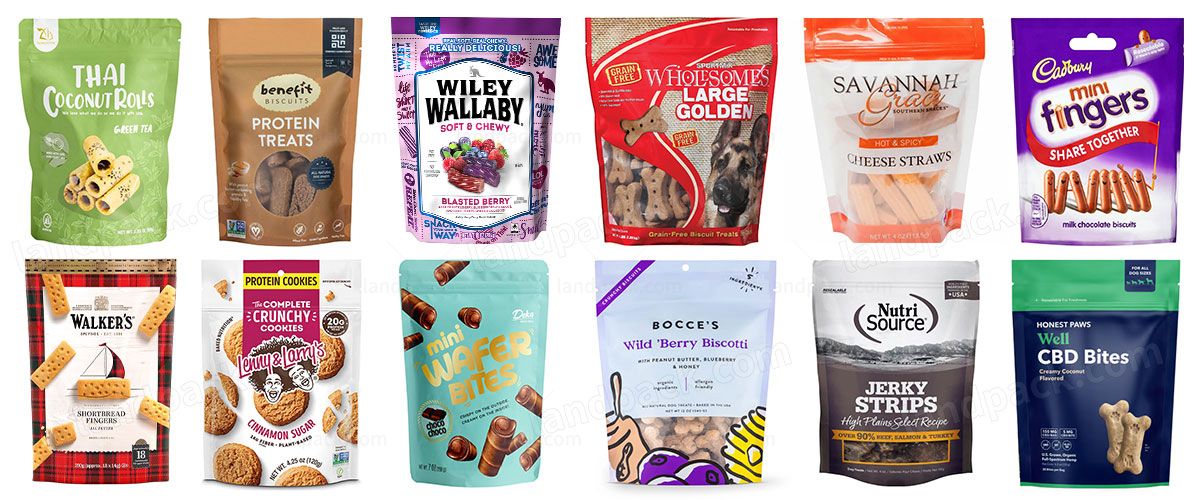

Packaging Samples :

| Model | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4-side sealing bag, Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag, etc. | |||

| Bag Size | 110-230mm(L), 80-160mm(W) | 70-100mm(L), 110-230(W) | 100-210mm(L), 110-320mm(w) | 100-260mm(L), 110-320mm(W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45 bags/min | 25-50 bags/min | 20-50 bags/min | 20-50 bags/min |

| Machine Weight | 800kg | 800kg | 900kg | 1000kg |

| Total power | 2KW | |||

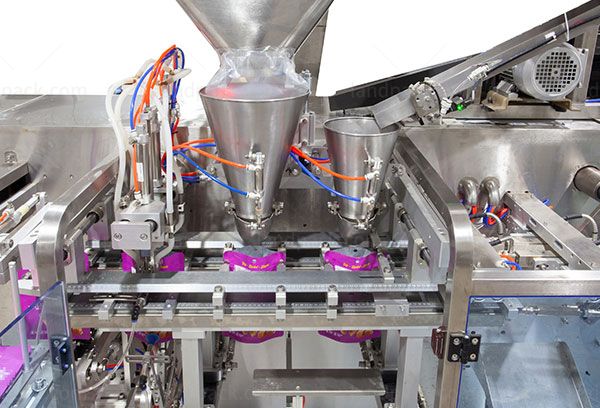

| Workflow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | |||

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | ||

| Collocation | Screw metering, screw elevator | |||

1. Efficient Automatic Feeding System: Features adjustable speed for smooth, continuous feeding that meets specific production demands.

2. High-Precision Weighing System: Equipped with a fast, accurate belt weigher to ensure optimal product measurement and minimize waste.

3. Reliable International Electrical Parts: Utilizes top-tier, globally recognized electrical components to guarantee stable and long-lasting operation.

4. Versatile Station Customization: Easily configurable for various bag types, such as stand-up pouches and other premade bags, providing flexible packaging options.

5. Dual Sealing Technology: Ensures strong, clean seals for a professional finish and preserves product freshness.

6. User-Friendly Control Interface: Features an intuitive touchscreen for quick, easy adjustments and monitoring of the packaging process.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail