Application:

Automatic Dry Powder Weighing Filling Machine Line. It is suitable for automatic weighing filling capping and labeling of various fluidic or low-fluidity powder materials like powder, granular additive, etc. It's widely used in the various industry including pharmaceutical, foodstuff, cosmetic and chemical.

Examples:

Milk powder, protein powder, coffee powder, medicine powder, chemical powder, meal replacement powder, etc.

Packaging Type:

Cans, Barrel, Bottles, Capsule, Cartons, Stand-up Pouch

Packaging Material:

Glass, Metal, Paper, Plastic, Wood, Other.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

Parameter:

| Automatic Powder Weighing Filling Capping And Labeling Machine (LF-PJ-W02) | ||

| Model | (LF-PJ-W02 | LFP-02 |

| Filling Weight | 10-5000g(customizable) | 10-5000g(customizable) |

| Bottle diameter | Φ30-Φ140mm(customizable) | Φ30-Φ140mm(customizable) |

| Bottle height | 50mm-200mm(customizable) | 50mm-200mm(customizable) |

| Yield | 10-20 Bottle/min | 20-40 Bottle/min |

| Measurement accuracy | ≤500g,≤±1%;>500g,≤±0.5% (Varies due to the characteristics of the material) | ≤500g,≤±1%;>500g,≤±0.5% (Varies due to the characteristics of the material) |

| Power | 2.5KW | 5KW |

| Silo capacity | 50L | 50L |

| Power Supply | 220V、50Hz | 220V、50Hz |

| Working Pressure | 0.6-0.8MPa | 0.6-0.8MPa |

| Weight | 350kg | 550kg |

Feature:

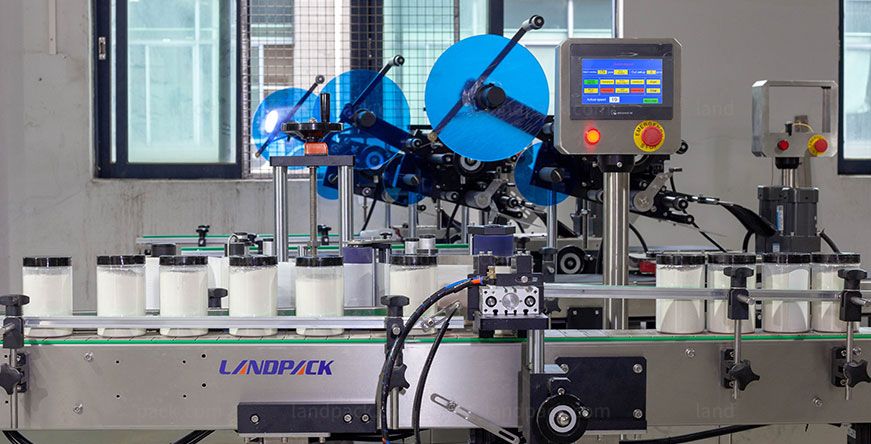

1.Automatic two-head Auger type metering/filling system works with the automatic capping machine.

2.Able to work with the double star wheels for bottle/can conveying & positioning system to perform the filling operation.

3.Conveyor is mounted a precision splitter to perform the intermittent movement for bottle/can to achieve the accurate positioning function.

4.Transmission system of the filling machine is driven by Japan Panasonic servo motor for high accuracy and stability.

5.Auto bottle/can positioning, lifting and vibrating, filling system is able to stop filling automatically when there's no bottle, and when bottle jammed occurs, the machine (system) will also stop automatically.

6.10 sets of memory modules for memorizing different kinds of products and filling weights.

7.HMI touch screen for operational control.

8.Japan Panasonic PLC.

9.Available to connect with material supply system at pre-section for auto linking connection.

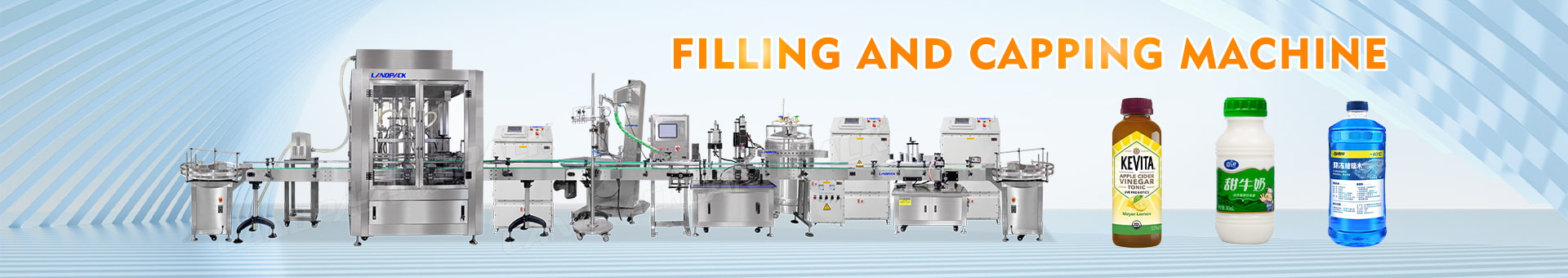

10.Available to link with the capping and labeling systems... etc. at post section.

Get Price & More Detail