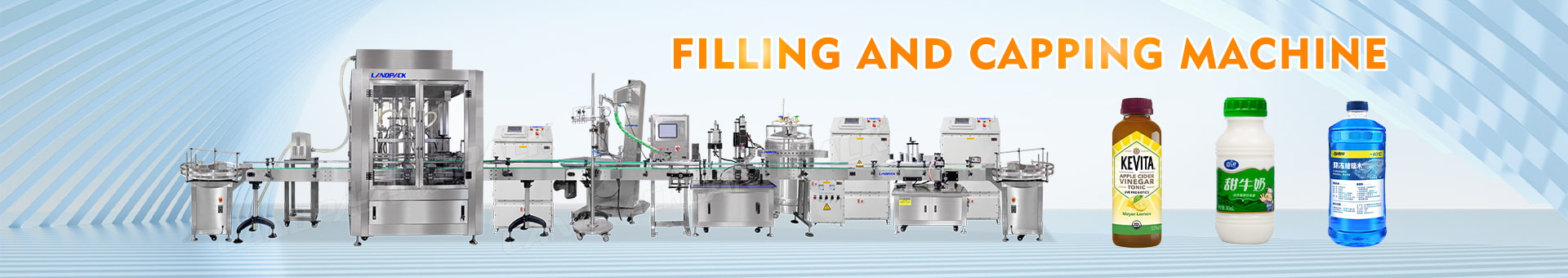

Automatic Liquid Spray Bottle Filling Capping Labeling Machine Nasal Spray Filling Production Line

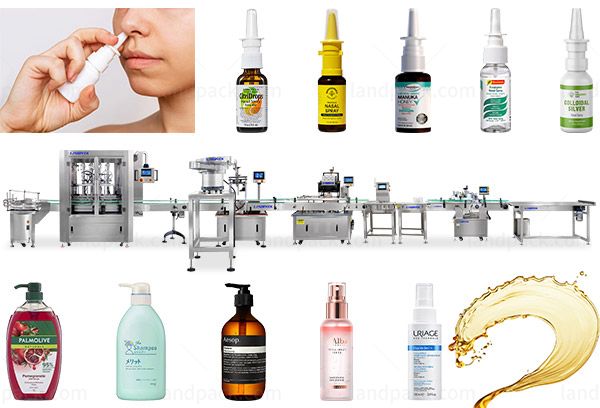

Application :

The Automatic Nasal Spray Filling, Capping, and Labeling Machine streamlines the packaging process for nasal spray bottles. The system automatically feeds empty bottles, fills them with precise liquid amounts, caps them securely, and applies labels.

Examples :

Designed for the pharmaceutical, cosmetic, and healthcare sectors, this production line ensures fast, accurate, and hygienic packaging of nasal spray products, meeting high industry standards.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

Parameter :

| Automatic Bottle feeder | |||

| Machine Model | LD-LP800N | ||

| Power Supply | 220V/110V, 50-60Hz, 200W | ||

| Turntable Diameter | 800mm | ||

| Suitable Bottle Diameter | 40-130mm | ||

| Suitable Bottle Height | 30-200mm | ||

| Working Speed | 40-60 bottles/min(depending on bottle size) | ||

| Package Size | 1230*1010*1260mm | ||

| Gross Weight | 141kg | ||

| Liquid Bottle filling machine | |||

| Model | LFZ-04 | ||

| Filling Range | 50-1000mlt (customizable) | ||

| Production Speed | <15-25 bottles/min | ||

| Measurement Accuracy | ±1% | ||

| Power | 2KW | ||

| Voltage | 220V, 50Hz | ||

| Air consumption | 0.6-8Mpa | ||

| Weight | 600kg | ||

| Dimension | L4000*W1320*H2090 mm | ||

| Autoamtic capping machine | |||

| Model | LFX-JX-01 (Four wheel capping) | LFX-GS-150(Eight wheel capping) | LFX-GS-250(Six wheel capping) |

| Capacity | 20-50 bottles/min | 40-100 bottles/min | 30-80 bottles/min |

| Bottle cap diameter | Φ22mm-Φ80mm(Could be customized) | Φ18mm-Φ80mm(Could be customized) | Φ18mm-Φ80mm(Could be customized) |

| Bottle diameter | Φ35mm-Φ140mm (Could be customized) | ||

| Bottle sealing height | 38mm-300mm (Could be customized) | ||

| Power | 1.5KW | 2KW | 1.5KW |

| Voltage | 220V, 50HZ | ||

| Air pressure | 0.6-0.8Mpa | 0.5-0.7Mpa | |

| Weight | 250kg | 350kg | 300kg |

| Dimensions | H3000*W800*L1600mm | H3120*W1544*L2122 | H3100*W1244*L2122 |

| Automatic Round Bottle Labeling Machine | |||

| Model | LFT-YP-00 | ||

| Labeling speed | 20-60 bottles/minute | ||

| Labeling Accuracy | ±1mm | ||

| Max Label Width | 100mm | ||

| Applicable Product Size | ф30mm~ф80mm(Can be customized) | ||

| Applicableinner diameter of paper | ф76mm | ||

| Applicable outer diameter of paper | Max.ф330mm | ||

| Air Source | 4-6 KG 30L/min | ||

| Dimension | 2000*800*1600mm | ||

| Voltage | 220V, 50 Hz, 2000W | ||

| Weight | 250KG | ||

Feature :

1. High-Precision 4-Head Piston Filling System: Offers accuracy up to ±1%, ensuring uniform filling and minimizing product waste across high-volume operations.

2. Automated Capping Solution: Includes an automatic cap feeder to enhance production speed and reduce manual labor.

3. Flexible Linear Capping Mechanism: Adapts easily to various bottle sizes without the need for mold changes, allowing for simple adjustments when switching products.

4. Smart Sensor Technology: Incorporates sensors that detect bottles in place, preventing unnecessary filling, capping, or labeling when bottles are absent, ensuring efficient use of materials.

5. Durable Stainless Steel Construction: The entire machine line is made from hygienic, easy-to-clean stainless steel, ensuring long-term durability and compliance with sanitary standards.

6. Fully Integrated Packaging Line: Combines filling, capping, and labeling in one unified system, reducing operational complexity and downtime while improving throughput.

7. Customizable Settings: Allows users to adjust operational parameters easily to accommodate different production needs, offering flexibility in packaging a variety of products.

Get Price & More Detail