Automatic Feeding Swabs Cotton Bud Flow Counting Wrapping Packing Machine

Model: LD-350X

Application:

This packaging machine is designed for the automatic counting and packaging of various types of swabs, including sterile cotton swabs, cotton buds, throat swabs, wipes, tissues, medical supplies, and similar products, anal swabs, nasal swabs, oral swabs, and specimen collection swabs. Making it a versatile solution for the healthcare and personal care industries.

Application:

This packaging machine is designed for the automatic counting and packaging of various types of swabs, including sterile cotton swabs, cotton buds, throat swabs, wipes, tissues, medical supplies, and similar products, anal swabs, nasal swabs, oral swabs, and specimen collection swabs. Making it a versatile solution for the healthcare and personal care industries.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

| Model | LP-250X | LP-350X | LP-450X | LP-600X | LP-700X | LP-800X | LP-900X |

| Film width | Max250mm | Max350mm | Max450mm | Max600mm | Max700mm | Max.800 mm | Max.900mm |

| Bag length | 65-190mm or120-280mm | 65-190mm or120-280mm | 150-450mm | 160-500mm | 180-600 mm | 210-650mm | 240-700mm |

| Bag width | 30-110mm | 50-160mm | 50-180mm | 100-280mm | 100-330 mm | 120-350mm | 150-400mm |

| Product height | Max.40mm | Max.40mm | Max.75mm | Max.110mm | Max.110 mm | Max.130 mm | Max.150mm |

| Film roll diameter | Max.320mm | ||||||

| Packaging rate | 40-230 bags/min | 40-180bags/min | 30-150Bags/min | 20-150 bags/min | 20-130 bags/min | 20-120bag/min | 20-100 bags/min |

| Power | 220V,50/60Hz,2.4kw | 220V,50/60Hz,2.6kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,4.5kw | 220V,50/60Hz,4.5kw |

| Machine size | (L)3770*(W)720*(H)1420mm | (L)4030*(W)770*(H)1420mm | (L)4030*(W)820*(H)1420mm | (L)4030*(W)970*(H)1500mm | (L)4030*(W)980*(L)1500mm | (L)4100*(W)1170*(H)1550mm | (L)4300*(W)1270*(H)1550mm |

| Machine quality | About 500kg | About 580kg | About650kg | About680kg | About720kg | About800kg | About 850kg |

| Remarks | optional air filling device)/optional angle folding) | ||||||

| Film material) | OPP/ PE/ PVC/ OPP/ CPP/ PT/ PE/ KOP/ CPP/ Aluminum Coating Film/ Aluminum Film | ||||||

1. Multi-language Interface: Provides easy-to-use, multilingual support for operators, simplifying machine control and setup.

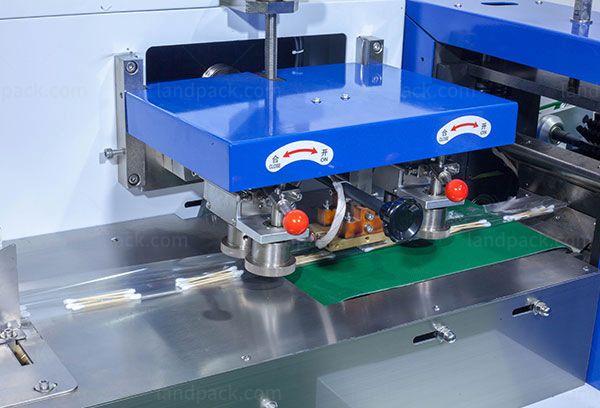

2. User-Friendly Operation: Simple operation allows for precise adjustments to sealing parameters for optimal packaging results.

3. Continuous Film Feeding: Guarantees smooth film feeding throughout production for uninterrupted operation.

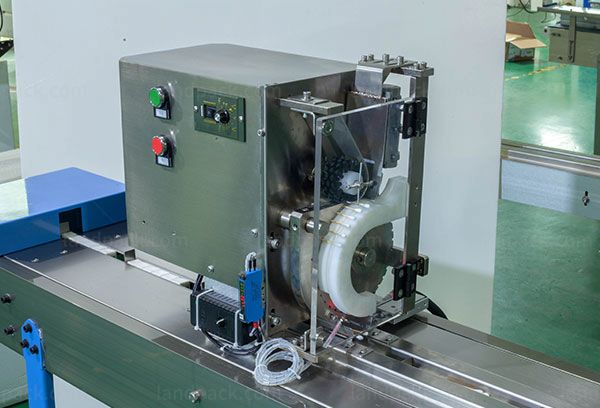

4. Automatic Counting and Loading: Automatically counts and loads cotton swabs onto the conveyor, enhancing efficiency in the packaging process.

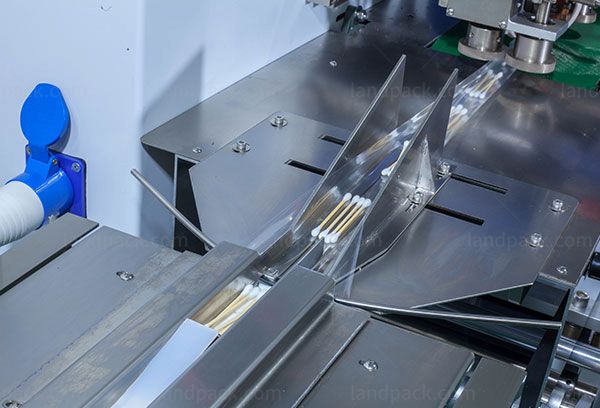

5. Alignment Mechanism: Ensures cotton swabs are neatly aligned and organized before packaging, improving presentation.

6. Anti-Empty Bag Detection: Equipped with a feature that prevents empty bags, reducing material wastage and optimizing production efficiency.

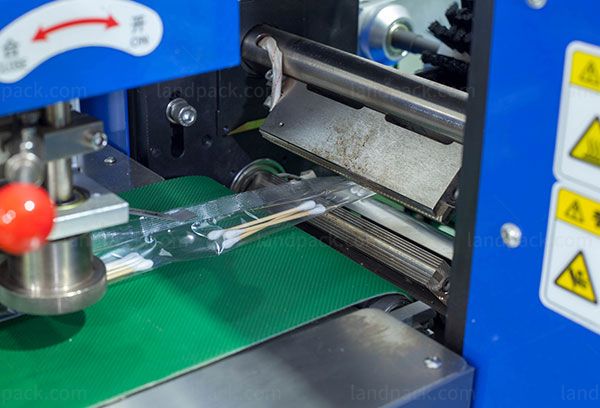

7. Reliable Performance: Delivers consistent, high-quality packaging results, ensuring each package is sealed properly.

8. Premium Sealing Quality: Ensures the production of neatly sealed, high-quality finished packages that meet industry standards.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail