Automatic Horizontal Pillow Bag Flow Wrapping Packing Machine

Model: LD-350B

Application:

Suitable for packaging various kinds of regular objects like soap, beef jerky, biltong, candy, biscuits, pies, popsicle, chocolates, Vegetable, bread, instant, noodles, moon-cakes, drugs, daily applications, industrial parts, paper boxes, tray, etc.

Advantage:

The pillow packaging machine can make the packaged product look neat and beautiful, and increase the added value of the product.

Application:

Suitable for packaging various kinds of regular objects like soap, beef jerky, biltong, candy, biscuits, pies, popsicles, chocolates, Vegetable, bread, instant, noodles, moon-cakes, drugs, daily applications, industrial parts, paper boxes, tray, etc.

Examples:

Soap, beef jerky, biltong, candy, biscuits, pies, popsicle, chocolates, vegetables, bread, instant, noodles, mooncakes, drugs, daily applications, industrial parts, paper boxes, tray, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

| Model | LP-250B | LP-350B | LP-450B | LP-600B | LP-700B | LP-800B | LP-900B |

| Film width | Max250mm | Max350mm | Max450mm | Max600mm | Max700mm | Max.800 mm | Max.900mm |

| Bag length | 65-190mm or120-280mm | 65-190mm or120-280mm | 150-450mm | 160-500mm | 180-600 mm | 210-650mm | 240-700mm |

| Bag width | 30-110mm | 50-160mm | 50-180mm | 100-280mm | 100-330 mm | 120-350mm | 150-400mm |

| Product height | Max.40mm | Max.40mm | Max.75mm | Max.110mm | Max.110 mm | Max.130 mm | Max.150mm |

| Film roll diameter | Max.320mm | ||||||

| Packaging rate | 40-230 bags/min | 40-180bags/min | 30-150Bags/min | 20-150 bags/min | 20-130 bags/min | 20-120bag/min | 20-100 bags/min |

| Power | 220V,50/60Hz,2.4kw | 220V,50/60Hz,2.6kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,2.8kw | 220V,50/60Hz,4.5kw | 220V,50/60Hz,4.5kw |

| Machine size | (L)3770*(W)720*(H)1420mm | (L)4030*(W)770*(H)1420mm | (L)4030*(W)820*(H)1420mm | (L)4030*(W)970*(H)1500mm | (L)4030*(W)980*(L)1500mm | (L)4100*(W)1170*(H)1550mm | (L)4300*(W)1270*(H)1550mm |

| Machine quality | About 500kg | About 580kg | About650kg | About680kg | About720kg | About800kg | About 850kg |

| Remarks | optional air filling device)/optional angle folding) | ||||||

| Film material) | OPP/ PE/ PVC/ OPP/ CPP/ PT/ PE/ KOP/ CPP/ Aluminum Coating Film/ Aluminum Film | ||||||

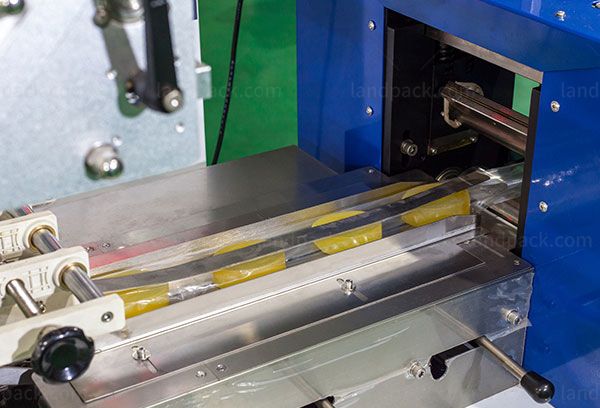

1.Dual frequency conversion control, Bag length can be set and cut in one step,saving time and film.

2.Interface features easy and quick setting and operation

3.Self failure diagnosis, clear failure display

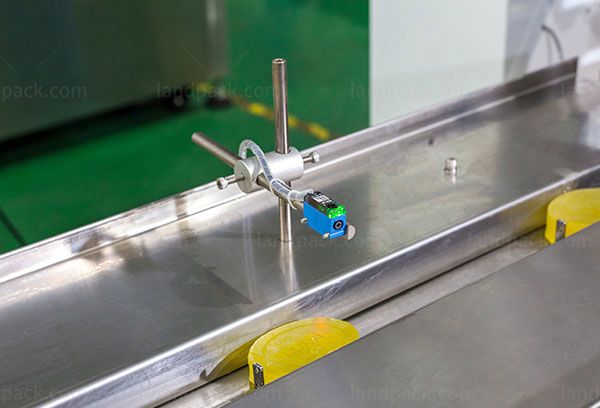

4.High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5.Temperature independent PID control, more suitable for packaging different materials

6.Positioned stop function, without sticking knife or wasting film.

7.Simple driving system, reliable working, convenient maintenance.

8.All control is realized through software,easy for function adjusting and technical upgrade.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail