Detergent Granule Pool Cleaning Powder Bottle Filling Capping Labeling Machine

Advantages :

This versatile packing machine is extensively used across the pharmaceutical, food, cosmetics, and chemical sectors.

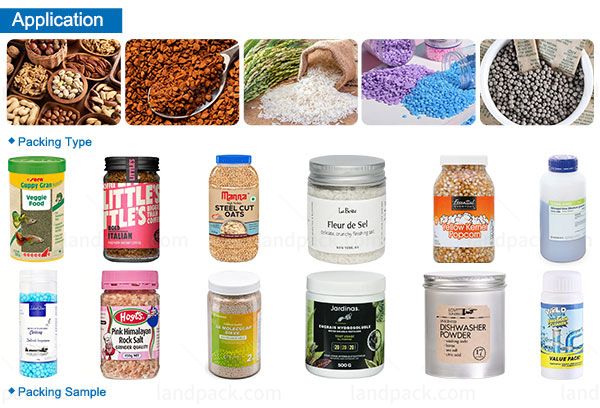

Application :

It is ideal for packaging a wide range of powdered products such as pool cleaning powder, protein powder, dishwashing powder, medicinal powder, meal replacement powder, chemical powder, milk powder, coffee powder, and detergent powder.

Application :

This versatile packing machine is extensively used across the pharmaceutical, food, cosmetics, and chemical sectors. With its efficient and reliable performance, it ensures consistent packaging quality for various powdered goods.

Exmaples :

pool cleaning powder, protein powder, dishwashing powder, medicinal powder, meal replacement powder, chemical powder, milk powder, coffee powder, and detergent powder.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

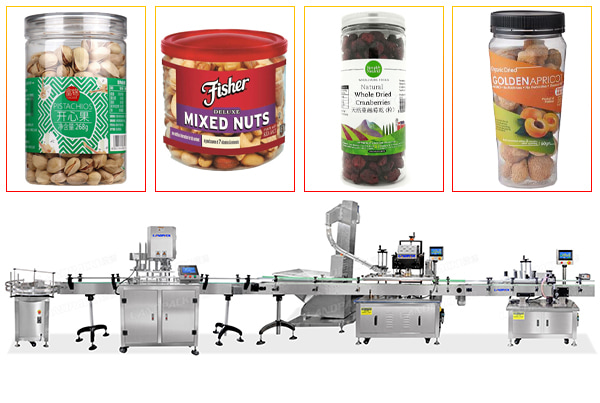

Packaging Samples :

| 4 Head Linear Scale Filling Machine | ||

| Filling Weight | 20-2000g | |

| Weighing Accuracy | +1-3g | |

| Speed | 15-25 bottles/minute | |

| Conveyor belt length | 2m | |

| Dimensions | L2000*W1000*H2000mm | |

| Hopper Capacity | 3000ml | |

| Material Arrangement | 20 | |

| Maximum ingredient category | 4 | |

| Power | AC220V, 50/60HZ | |

| High Speed Capping Machine | ||

| Model | LFX-GS-150 (Eight wheel capping) | LFX-GS-250 (Six wheel capping) |

| Capacity | 40-100 Bottles/min | 30-80 bottles/min |

| Bottle cap diameter | ф18mm-ф80mm (Could be customized) | ф18mm-ф80mm (Could be customized) |

| Bottle diameter | ф35mm-ф140mm (Could be customized) | ф35mm-ф140mm (Could be customized) |

| Bottle sealing height | 38mm-300mm (Could be customized) | 38mm-300mm (Could be customized) |

| Power | 2KW | 1.5KW |

| Voltage | 220V, 50HZ | 220V, 50HZ |

| Air pressure | 0.6-0.8Mpa | 0.5-0.7Mpa |

| Weight | 350kg | 300kg |

| Dimensions | H3120*W1544*L2122 | H3100*W1244*L2122 |

| Automatic Labeling Machine | ||

| Model | LFT-YP-00 | |

| Labeling Speed | 20-60 bottles/minute | |

| Labeling Accuracy | ±1mm | |

| Max Label Width | 100mm | |

| Applicable Product Size | ф30mm-ф80mm (Can be customized) | |

| Applicable inner diameter of paper | ф76mm | |

| Applicable outer diameter of paper | Max.ф330mm | |

| Air Source | 4-6 KG, 30L/min | |

| Dimension | 2000*800*1600mm | |

| Voltage | 220V, 50 Hz, 2000W | |

| Weight | 250KG | |

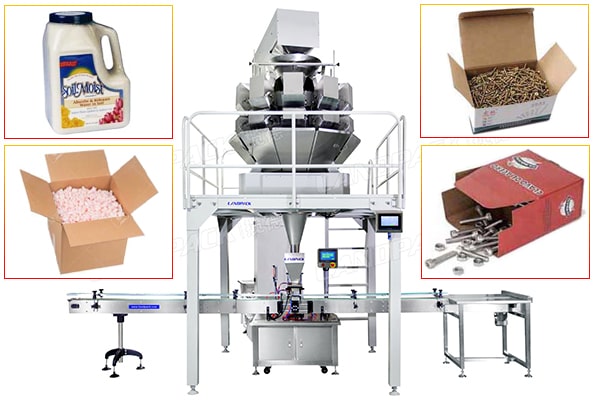

1. Wide Application Range: Specially designed for filling detergent powder and pipe-cleaning granules, making it adaptable to diverse industrial needs.

2. Flexible Bottle Handling: Accommodates a variety of bottle shapes and sizes, ensuring compatibility with different packaging requirements.

3. Versatile Capping Solutions: Integrated with multiple capping options to support efficient sealing across various product types.

4. High-Accuracy Labeling: Advanced labeling system guarantees precise and smooth application for a professional finish.

5. Optimized Production Efficiency: Compact shared production lines save floor space while multifunctional equipment reduces operational expenses.

6. Integrated Quality Control: Includes automated checking systems to ensure consistent filling accuracy and labeling precision, enhancing product reliability.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail