Application :

Commonly used for packaging a variety of products, including fertilizers (horticultural, fruit and vegetable), coffee beans, frozen foods, cookies, cereals, nuts, dried fruit, candy, flowers, and more, ensuring efficient and precise packaging of granules and other items.

Packaging Material:

Glass, Metal, Paper, Plastic, Wood, and Others.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

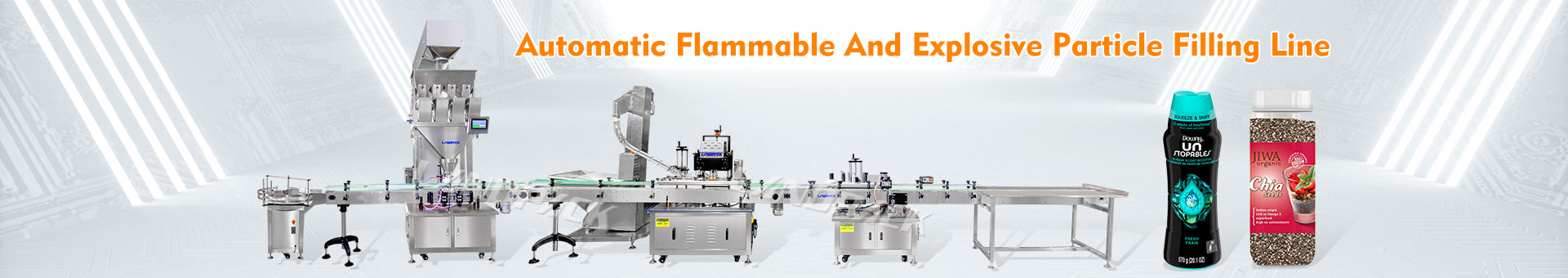

Packaging Sample:

Parameters:

| Automatic Bottle feeder | |

| Power Supply | 220V/110V, 50-60Hz, 200W |

| Turntable Diameter | 800mm |

| Suitable Bottle Diameter | 40-130mm |

| Suitable Bottle Height | 30-200mm |

| Working Speed | 40-60 bottles/min(depending on bottle size) |

| Package Size | 1230*1010*1260mm |

| Gross Weight | 141kg |

| Linear scale filling machine | |

| Model | LD-LS01 |

| Filling Range | 1-10KG (Customizable) |

| Weighing precision | +1-3g |

| Filling speed | 15-25 PCS/min |

| Conveyor belt length | 2m |

| Size | L2504*W1000*H2321mm |

| Hopper capacity | 3000ml |

| Material arrangement | 20 kinds |

| Maximum ingredient category | 2 kinds |

| Power | Single phase AC220V 50/60Hz |

| Automatic Caps Feeder | |

| Model | LD-VTYG01 |

| Voltage | 110V/220V |

| Capacity | 15-18 bottles/min |

| Applicable Container | L: 40-110mm, W: 40-110mm, H: 40-110mm |

| Applicable Lid | Customizable |

| Packing Size | About 2080*940*1730mm |

| Gross Weight | About 261kg |

| Automatic Caps Pressing Machine | |

| Cover method | Elevator cap sorting |

| Capping form | Chain piece type capping |

| Application bottle | According to the customer's product |

| Capping speed | 30-50 bottles/min |

| Capping voltage | 1ph AC 220V 50/60Hz |

| Air pressure | 0.6-0.8MPa |

| Dimension | 1300(L)*850(W)*1660(H)mm |

| Packing size | 1400(L)*950(W)*1760(H)mm |

| Machine weight | About 400KG |

Feature:

1.Efficient and Automated Process – The system automates every step from container loading to weighing, filling, cap insertion, and capping, minimizing manual labor and boosting overall productivity.

2.Versatile Filling Range – Capable of handling container sizes from 1L to 10L, this system offers fast changeover between different production runs, optimizing cost-efficiency and enhancing throughput.

Workflow:

1. Auto feeding the containers

2. Auto weighing and filling

3. Auto feeding the caps

4. Pressing and capping

5. Output collecting

Get Price & More Detail