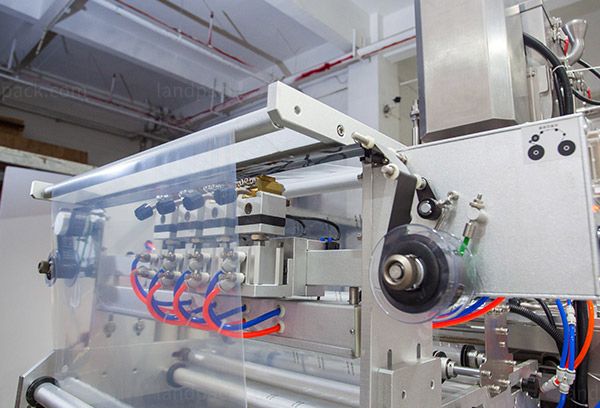

Multi Lanes Shaped Pouch Sachet Liquid Filling Packing Machine With Heating Stiring Device

Model : LD-480-4

Application :

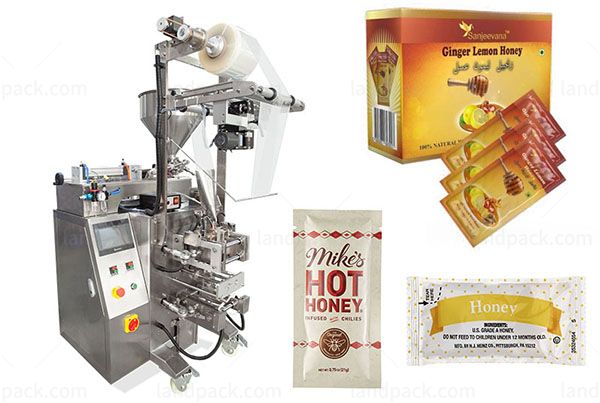

This machine is highly versatile, perfect for packaging a wide array of food, pharmaceutical, and chemical liquid products. It is ideal for items such as sauces, honey, pastes, ketchup, body wash, creams, shampoo, flavorings, and more.

Application :

This machine is highly versatile, perfect for packaging a wide array of food, pharmaceutical, and chemical liquid products. Designed for efficiency and accuracy, it ensures precise packaging for various liquid and semi-liquid goods.

Examples :

sauces, honey, pastes, ketchup, body wash, creams, shampoo, flavorings, and more.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

Model | LD-480Y | LD-720Y | LD-960Y |

| Track Number | 4-6 Track | 4-10 Track | 4-12 Track |

| Filling Method | 1. Piston pump; 2. Peristaltic Pump | ||

| Production capacity | Max. 240 bags/min | Max. 400 bags/min | Max. 480 bags/min |

| Sachet Size | L: 45-120mm; W: 35-60mm | L: 45-120mm; W: 35-90mm | L: 45-120mm; W: 35-120mm |

| Film Width & Thickness | Max.480mm; 0.07-0.1mm | Max.720mm; 0.07-0.1mm | Max.960mm; 0.07-0.1mm |

Sealing Type | 3/4 sides sealing | ||

Cutting Type | 1. Straight Cutting; 2. Zig Zag Cutting; 3. Continuous Cutting | ||

Air & Power | 0.8 mpa, 0.8 m³/min, 2.8kw | 0.8 mpa, 0.8 m³/min, 4.1kw | 0.8 mpa, 0.8 m³/min, 5.5kw |

| DIM & WT | 950*1470*1750mm; 300kg | 1153*1654*1750mm; 400kg | 1415*1686*2130mm; 500kg |

1. Automatic Feeding and Filling System: Ensures seamless and efficient liquid transfer into irregular sachets with precise dosing.

2. Advanced Rotor Pump Technology: Effectively handles thick or sticky liquids, ensuring smooth and reliable operation for a wide range of liquid materials.

3. High-Precision Ceramic Pump: Delivers accurate measurements, guaranteeing product consistency and meeting strict quality standards.

4. Customizable Packaging Options: Designed to cater to specific customer needs, offering flexibility for unique product specifications and requirements.

5. Enhanced Production Efficiency: Optimizes performance through advanced technology, reducing material waste while maximizing output.

6. Easy Integration and Operation: Features a user-friendly interface for straightforward operation and maintenance, facilitating smooth integration into existing production lines.

7. Quick Changeover Capability: Designed for rapid adjustments, reducing downtime and improving overall operational efficiency.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail