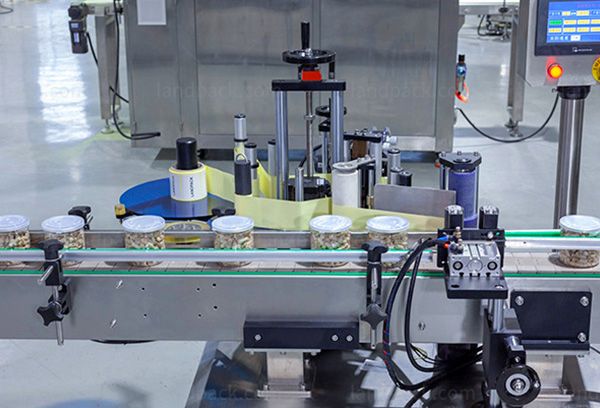

Automatic Inline Bottle Filler Machine Guanule Food Canning Packing Line

Model : LD-AF01

Application :

This automated inline filler system is designed for a wide range of dry, free-flowing granular products, such as snack, dry food, oatmeal, corn flakes, rice,peanut, popcorn, chips, nuts, seeds, candy, dry fruits, pet food, etc. Suitable for all kinds of containers on the market, such as plastic cans, jars, bottles, etc.

Application :

This automated inline filler system is designed for a wide range of dry, free-flowing granular products, such as snack, dry food, oatmeal, corn flakes, rice,peanut, popcorn, chips, nuts, seeds, candy, dry fruits, pet food, etc. Suitable for all kinds of containers on the market, such as plastic cans, jars, bottles, etc.

Packaging Type :

It is suitable for various materials, and various bottle types, and has a wide range of applications.

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

| Model | LD-AF01 | |

| Measure method | Electroni weigher/Piston filler/Pump | |

| Sealing height | 50-200mm | |

| Filling weight | Max5000ml | |

| Packaging precision | ≤0.3-1% | |

| Packaging speed | Max50pcs/min (Depend on the product characteristic) | |

| Power supply | Three phase 380/220V 50-60Hz / 2kw | |

| Pressure | 6-8 kg/cm2 0.3m3/min | |

| weight | 500kg | |

| Dimension (mm) | 3000x900x1800mm | |

1.The production line utilizes advanced automation technology with imported PLCs, photoelectric sensors, frequency converters, and premium pneumatic components for reliable operation.

2.Fully automated processing includes automatic bottle feeding, linear filling, sealing, labeling, and collection systems in one integrated line.

3.Compatible with various market containers including plastic cans, metal tins, and pre-made pouches for versatile applications.

4.Constructed with SUS304 stainless steel framework for both aesthetic appeal and long-term durability.

5.Features quiet, stable operation with easy maintenance, fully GMP compliant for pharmaceutical and food industry standards.

6.User-friendly control system with imported PLC and 7-inch touchscreen interface for intuitive operation.

7.Customizable configurations available to meet specific customer requirements and production needs.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail