Automatic Beef Jerky Biltong Ziplock Bag Doypack Packing Machine With Nitrogen Filling Function

Model : LDB-300A

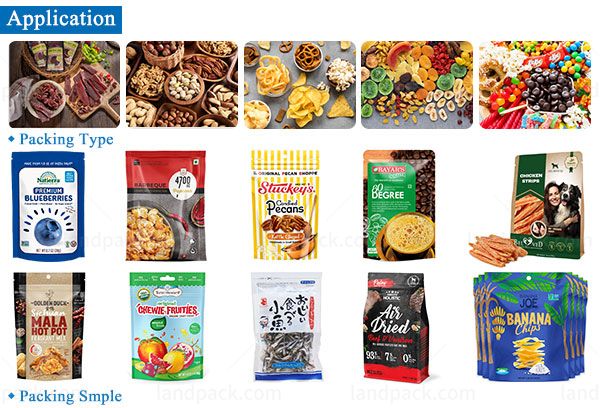

Application :

It is ideal for packaging beef jerky, biltong, dried meats, melon seeds, roasted seeds, peanuts, pistachios, almonds, cashews, and other nuts, as well as coffee beans, chips, raisins, plums, cereals, and a variety of snacks. The machine also caters to pet food, puffed foods, vegetables, dehydrated fruits, seafood, frozen foods, and even small hardware, offering versatility for numerous applications.

Application :

This machine is widely utilized across a diverse range of industries for packaging various products, including candies, chocolates, jelly, pasta, grain, sticks, slices, round, and irregularly shaped items.

Examples :

It is ideal for packaging beef jerky, biltong, dried meats, melon seeds, roasted seeds, peanuts, pistachios, almonds, cashews, and other nuts, as well as coffee beans, chips, raisins, plums, cereals, and a variety of snacks. The machine also caters to pet food, puffed foods, vegetables, dehydrated fruits, seafood, frozen foods, and even small hardware, offering versatility for numerous applications.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers:

| Type | Automatic Beef Jerky Biltong Ziplock Bag Doypack Packing Machine With Nitrogen Filling Function | ||

| LDB-200 | LDB-300 | LDB-430 | |

| Bag Material | Multi-layer Composite Premade Bag(e.g.: PET/PE) | ||

| Premade bag type | 3-sides sealing bag, stand-up bag) | ||

| Upgraded Bag Type | (Need additional purchase of functional device) | Gusset Bag, Zipper Bag, box bag (Need additional purchase of functional device | |

| Bag size | 70mm≤W≤150mm | 80mm≤W≤300mm | 80mm≤W≤300mm |

| 70mm≤L≤150mm | 100mm≤L≤300mm | 100mm≤L≤430mm | |

| Speed | 0~60bags/min | 0~15bags/min | |

| Sealing Type | Straight grain, pitch is 1mm (Optional reticulate) | ||

| Sealing Width | 10mm(5--20mm) can be customized | ||

| Voltage | 220V, Single-phase,50/60HZ, 1.2KW | ||

| Air Pressure | 0.65Mpa | ||

| Air Consumption | Standard machine, no additional function | ||

| Body Dimension | 1770*600*1230mm | 1770*600*1360mm | |

| Packing Dimension | 1860*710*1550mm | 1860*710*1650mm | |

| Export non-fumigation wooden case | |||

1. User-Friendly Operation: Designed for easy handling, ensuring a smooth and intuitive experience for operators.

2. Automatic Error Detection: Equipped with an automatic checking system to detect pouch errors, such as missing pouches, open pouches, or sealing issues, minimizing waste.

3. Safety Features: Includes a safety device that halts machine operation in the event of abnormal air pressure or heater disconnection, protecting both the equipment and operators.

4. Adjustable Bag Size: Offers flexibility with adjustable bag width, accommodating various pouch sizes for diverse packaging needs.

5. Glass Safety Door: The machine automatically stops when the door is opened, ensuring operator safety during maintenance or adjustments.

6. Minimal Material Loss: High-quality sealing reduces waste, improving packaging efficiency and enhancing product presentation.

7. Versatile Feeding Hoppers: Compatible with multiple hopper types for packaging solid, liquid, thick liquid, and powder products.

8. Wide Bag Material Compatibility: Works with a broad range of bag materials, offering flexibility in packaging solutions.

9. Specialized Long Product Pushing Device: Includes a dedicated device for efficiently handling long products, ensuring smooth packaging.

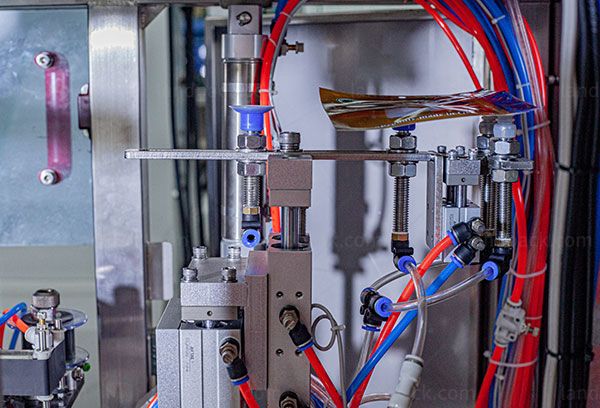

10. Zipper Opening and Nitrogen Filling: Features a zipper opening system with optional nitrogen filling for improved product preservation and freshness.

11. Dimpled Surface Weigher: The weigher's dimpled surface prevents product from sticking, ensuring precise and clean weighing.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail