We are the manufacture with over 15years experience of producing filling capping and labeling machine.

Here is our 4 heads piston filling capping machine printing line for sauce.

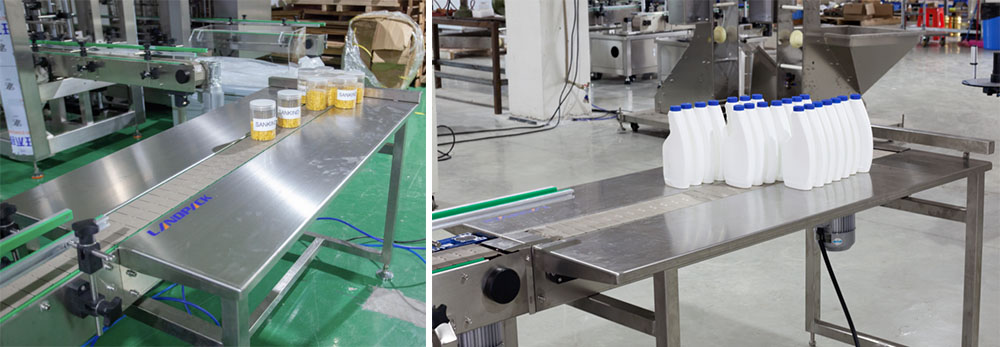

(Bottle sample pictures for your reference)

Recommendation :

1.4 Headas piston filling machine:Can filling 100-1000ml,the filling speed is abotu 720-1200bottles/hour,that depending on you filling range and bottle mouth size.

2.Capping machine:Suitable for different size screw cap,when you change different size cap dont need to change any spear part,only need to adjust the capping heads size.

3.Labeling machine:Can suitable for round bottle labeling and square bottle 2 side and 4 side labeling,only need to set the labeling way in touch screen.

4 heads piston filling machine:

Feature:

1. Piston filling machine, self-priming filling, the material is driven by a single cylinder to drive a single piston to extract the material into the metering cylinder, and then the piston is pneumatically pushed into the container through the material tube. High installation accuracy, easy to use and flexible;

2. Filling capacity can be adjused by the touch screen directly

3. All machine frame is made of SS304 to ensure the longer lifetime 4.The highest filling temperature is within 70 ℃;

5.Equipped with no bottle and no filling function, the liquid level automatically controls feeding, effectively reducing equipment failure;

6.The material of the feeding hose is PVC, the temperature range: -10 ℃ ~ + 90 ℃

Capping machine:

Feature:

1.Renewal bore size need disassemble the cover groove and adjust the cover arrange hoist machine and cover revolve wheel, the adjustment time is 30 minutes;

2. Manually rock the screw rod and adjust the cover revolve head to change bottle height, the adjustment time is 5-10 minutes;

3..Adopt PLC intelligent program design add touch screen control, convenient and simple to use and set;

4.Strong usability, suit to common cover, high cover, press nozzle cover and fog spraying cover, cover arrange part can pertinence customer made according to requirements;

5.This machine need additionally configure air compressor, need the air source pressure bigger than 0.5-0.7MP

Labeling machine:

Feature:

1.This machine adopts computer optical fiber control, synchronous tracking, the standard is controlled by mutual inductance inductance step motor to ensure that the standard speed is synchronized with the bottle speed. It is a modern mechatronics product with excellent and reliable working performance.

2.Automatic bottle dividing: the bottle dividing mechanism is adopted to effectively eliminate the bottle dividing difficulty caused by the error of the bottle itself and improve the stability;

3.Touch screen control: the man-machine interface has the function of operation and instruction, the parameter modification is intuitive and clear, and the switching of various functions is simple;

4. Intelligent control, automatic photoelectric tracking, with no label, no label automatic correction and label automatic detection function, to avoid waste labels and missing stickers;

Inkjet printer machine:

Feature:

1.Customized printe information under the bottle bottle

2.Customize rotary head ,rotary any direction

3.Printing height:1.2-15mm

4.Customized conveyor

5.extra 5pcs ink box for replace

6.Speed:320m/min

7.Non-contact printing distance 2-15mm

8.Maximum printing dots:25 dots(2-3row)

9.SuItable for plastic bottle and glass bottle

Collection platform:

If you interesting in our machine,please contact us,thanks!