We are the manufacture with over 15years experience of producing filling capping and labeling machine.

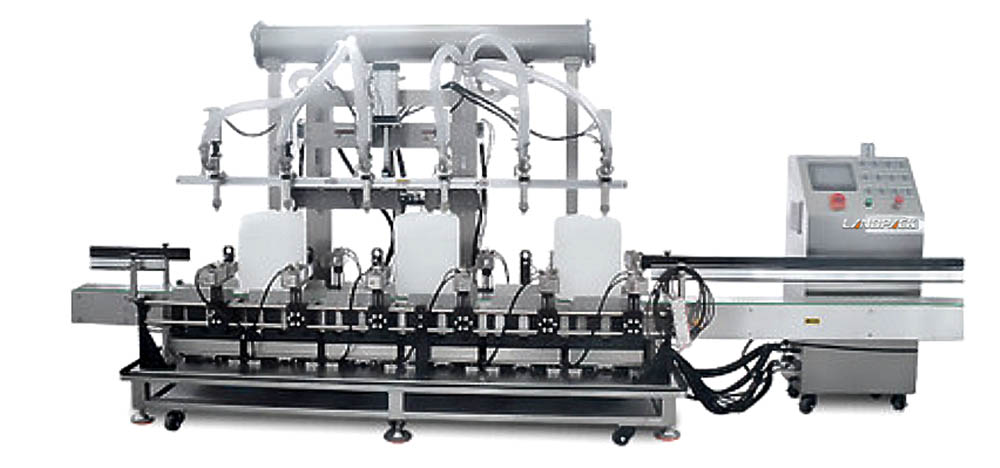

Here is our 4 heads weighing filling capping machine printing line for sauce.

(Bottle sample pictures for your reference)

Recommendation:Just two workers is can operate this filling machine production line

1.4 heads filling machine:

When filling 20L,the filling speed is about 400-500bph;

The filling accuracy is about ± ≤0.25%;

The filling capacity of each filling head can be changed on the touch screen directly"

2.Capping machine:Use the servo capping machinw with cap feeder,can save labor.

3.Labeling machine:Can suitable for the square bottle one side labeling with the sticker label

4 heads weighing filling machine:

Feature:

1.The system adopts weighing type filling with high measuring accuracy and is not affected by materials.

2.The measurement range is large, and the measurement error is plus or minus ± ≤0.25% per barrel. (Calculated by 20L)

3.PLC touch screen control system has the advantages of stable operation, strong anti-interference, high weighing accuracy and convenient operation of man-machine interface.

4.The filling with accurate positioning, high precision, fast speed, large torque, long service life, adjustable speed and good stability.

5.Contact with materials are made of 304 stainless steel, which can be used for the packaging of general corrosive chemical products.

6.Is an easy to operate filling machine. With stable and reliable operation, high production efficiency, strong adaptability.

7.No bottle no filling .

Capping machine:

Feature:

1.The capping machine is an important part of the production line, which completes the capping of the counterweight barrel.

2.The capping machine is one-time capping to ensure the tightness of the capping and the flatness of the cap after capping.

3.The capping machine positions the heavy barrel directly below the capping plate, and then performs capping work after positioning

Labeling machine:

Feature:

1.This machine adopts computer optical fiber control, synchronous tracking, the standard is controlled by mutual inductance inductance step motor to ensure that the standard speed is synchronized with the bottle speed. It is a modern mechatronics product with excellent and reliable working performance.

2.Touch screen control: the man-machine interface has the function of operation and instruction, the parameter modification is intuitive and clear, and the switching of various functions is simple;

3. Intelligent control, automatic photoelectric tracking, with no label, no label automatic correction and label automatic detection function, to avoid waste labels and missing stickers;

If you interesting in our machine,please contact us,thanks!