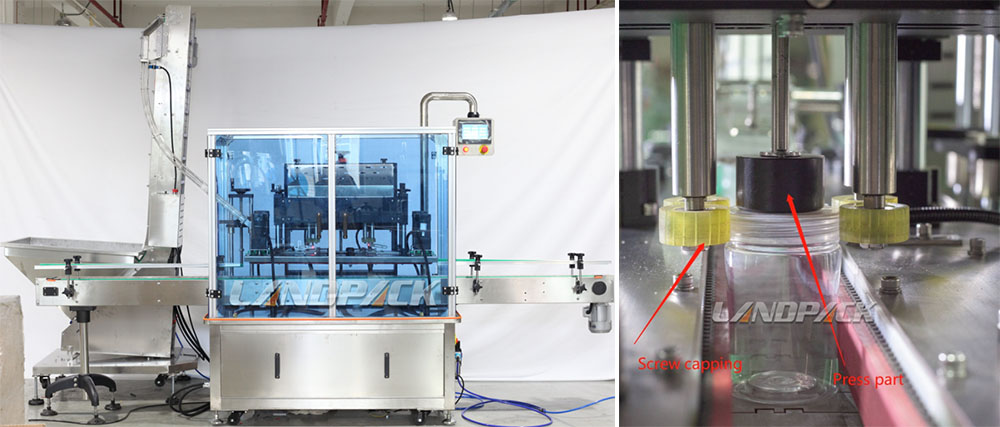

Two heads screw cap capping machine:

1.The machine is mainly composed of bottle conveying mechanism, capping mechanism, clamping bottle conveying mechanism, screw capping mechanism, electric control system, high degree of automation, reasonable design, compact structure, easy to operate;

2.The machine frame, components and outer frame are mainly made og high-quality stainless steel,with beautiful in appearance, easy to in line with CMP requiremants.

3.The structure is simple and reasonable stable and reliable , the performance is stable asn reliable,and the working efficiency is high, The rub type capping technology effectively solves the problem of traditional capping machine,such as slipping and damage.

4.The distance and height of capping mechanism can be adjusted quickly, which can adapt to different bottle types and cap;

5.The cap feeding mechanism is equipped with a photoelectric induction safety protection device, which can control the bottle arranging mechanism to realize the self-protection function of "start the machine without cap and deliver the cap when the machine is not enough,and do not deliver the can when the machine is full", thus enhances the operation stability and reliability of the equipment.

Feature:

The 2 heads capping machine is tighten the cap while screwing the cap, and can set the torque of screwing the cap. Designing the appropriate torque can realize the tightening and stop.

This way the packaging cap is tightened and will not wear the cap,The roller type capping head is always screwing.

Machine details:

| Touch screen | Intelligent touch screen, perfect system, simple operation, adjustable labeling speed |

| Cap sensor | The cap feeding mechanism is equipped with a photoelectric induction safety protection device, which can control the bottle arranging mechanism to realize the self-protection function of "start the machine without cap and deliver the cap when the machine is not enough,and do not deliver the can when the machine is full", thus enhances the operation stability and reliability of the equipment. |

| Capping device | The clamping, pressing and capping movements are precise and strength reasonable. Avoid the deformation of the bottle clamp problem of over-tightening or over-loose of the cap |

| Manual adjustment wheel | It can be applied to bottle caps of different bottle sizes through the hand-operated adjustment wheel. |

| Electric box layout | The accessories in the electric box are selected from well-known brands, and the arrangement is more reasonable, which is conducive to heat dissipation and later maintenance. |

Why choose us?

1. Our factory has over 15 years experience in filling capping machine area, very professional;

2. We can make customized machine according to customer's requirements and the bottle and cap sample.

3. We have a professional team of engineers who can provide stable after-sales service.

4. We have a professional team of engineers who can independently develop machines and update machine quality.

5. We have a machine shop that produces precise parts in-house,the cost of the machine is lower and the price is higher.So we offer the best price for machine.