How to Choose Liquid Filling Machine

Hello everyone ,this is Bella from LANDPACK, sale engineer manager ,today I’d like to introduce our liquid filling line machine to us ,

There are 2 type of filling machine

First is servo piston filling machine ,this type filling machine, the material is driven by a single cylinder to pull the material into the measuring cylinder, and then the piston is pneumatically pushed into the container through the feeding tube. The filling volume is determined by adjusting the cylinder stroke, and the filling accuracy High,easy to use and flexible;as below :

Suitable for the filling of various liquids, pastes, sauces(high viscosity), such as honey, pepper sauce, tomato sauce, pearl milk tea, orange juice, etc., with strong versatility

Second is the self-flow filling machine, widely used for filling low-viscosity non-gas liquids such as milk, wine, drinking water, etc., as well as various food and beverages (such as tea drinks, soy sauce, wine, vinegar, etc.), medicine, chemicals, pesticides can be used for filling all kinds of easy-flowing liquids in industries.as below

Features:

1, Equipped with no bottle and no filling function, the liquid level automatically controls the feeding, effectively reducing equipment failure;

2,Program control adopts PLC + touch screen manual operation interface to realize intelligent control

3,To adjust the filling volume, each piston cylinder needs to be adjusted one by one;

4,Materials in contact with liquids : 304 # stainless steel and food-grade PVC;

5,The filling nozzle is made of stainless steel 304, which is corrosion resistant and meets GMP production requirements;

6,The material of the feeding hose is PVC, the temperature range is -10 ℃ ~ + 90 ℃;

7,The highest filling temperature is within 70 ℃;

8,Strong equipment compatibility, can quickly adjust and replace bottles of different shapes and specifications without replacing parts

9, Bottle filling machine, no bottle without filling, liquid level automatic control feeding, convenient, fast and save labor;

10, The filling mouth is equipped with anti-drip device to ensure that there is no drawing or dripping during filling;

11,The material of the conveyor belt is nylon POM, which has good wear resistance

How to confirm what’s type machine can fill your product ?

first you need confirm your product viscosity ?

1,fluid,if you product viscosity range is 1-100cp(1cp=0.01Pa.s),such as water ,beer ,pure juice,milk ,vinegar, soy sauce oral liquid, injection etc........

Above product you need to choose self-flow filling machine

2,Semi-fluid,its viscosity within 100cp-10000cp,such as ketchup,honey,sugar sauce ,etc.....

Above product you need to choose servo piston filling machine .

3,High viscosity product ,this product viscosity range is over 10000cp ,it can’t flow at all ,this product the filling machine can’t fill it .

How To Choose How Many Filling Nozzles is suitable to you

Well it depends on your output capacity ,usually 1 filling nozzle speed is 5-8pcs per minute (when fill 500ml product) , such as if you need 20pcs output per minute ,then 4 filling nozzles machine is most suitable for you ,also we have 6 filling nozzles ,8 filling nozzles ,10 filling nozzles ,12,14 etc ...

Below is 10 filling nozzle

How to choose filling machine if you need to fill different capacity product ,and you have different bottles or Jars ,

Within small range of the capacity ,it can use same machine, such as 30ml-1000ml can use 1set filling machine ,1L-3L we advise to use 1set machine ,3L-5L we advise to use 1set machine is ok ,

But if you want to fill maybe 50ml-3L or more ,it’s not sensible,because the filling nozzles are customized according to your smallest bottle ,when you fill 50ml bottle ,it’s no problem ,but if you use this so small filling nozzle to fill 3L bottle ,speed will be very slow (because 3L bottle maybe very big ) and you need to adjust many device once you change the bottle ,it will spend too much labor cost and time cost ,in case your workers are not engineer ,it’s difficult for them to change the device and adjust the machine .

Beside we also produce capping machine and labeling machine ,it can match with the filling machine with whole line ,here I share one type capping machine and labeling machine .

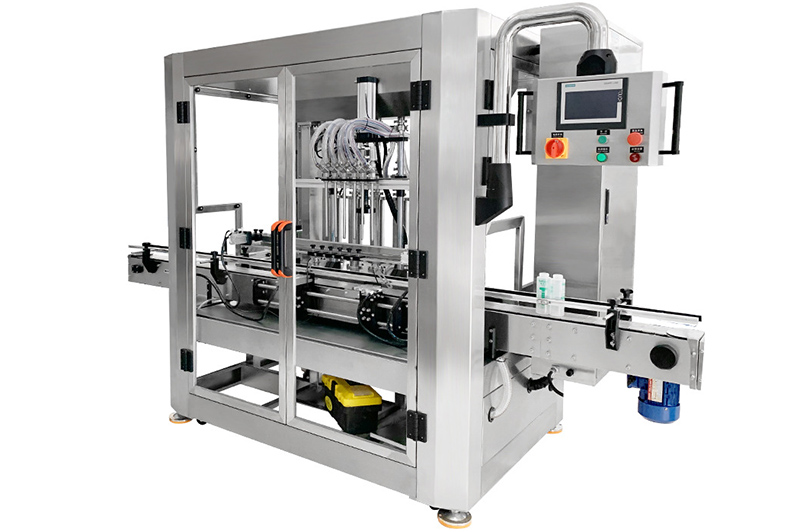

Above is the capping machine

Above is the labeling machine

There are so many type capping machine and labeling machine ,they are customized according to your caps and bottle type , our professional R&D team will help you to customize the best solution for you ,

Ok ,next time I will share more information about how to choose the capping machine and labeling machine !

Thanks for your reading !