Flour or wheat flour is a kind of powder ground from wheat or other grains. It is one of the most common food raw materials in the world. It is often necessary to add water to make dough, and then steam and bake it. Wheat flour is divided into special flour, general-purpose flour, and nutrient-enhanced flour according to performance and use. According to precision, it is divided into special first-grade flour, special second-grade flour, standard flour, ordinary flour, etc. According to gluten strength, it is divided into high-gluten flour, medium-gluten flour and low-gluten flour. Flour is responsible for most of the "staple food" and "desserts" in human food, such as various breads, steamed buns, cakes, noodles, cakes, biscuits, etc. are all made from flour.

In Chinese, "flour" without a description refers specifically to "wheat flour", but things like "barley, oat, buckwheat, rye" can also be used as flour. Because China, India, and the United States, the three most populous countries, consume wheat flour as the staple food, the yield of wheat flour is much higher than that of other grains.

As we all know, flour is a very dusty powder, but various types of flour can be perfectly sorted and packaged and appear in every corner. So, do you know how these flours are packaged? LANDPACK Packaging Machinery has been committed to customizing suitable packaging machines for various products for more than 15 years, have rich experience. The machines produced in our factory can pack flour without raising dust. Let me introduce to you one of our packaging machines for packaging powder:

This is a pre-made bag powder packing machine, if you already have product bags, this machine will be a good choice. As you can see, the powder is sealed in the hopper and has no direct contact with the air, which can not only keep the environment clean and tidy, but also make the powder packaged in a clean environment, so that customers can be more assured. All parts of our machine contacting materials are made of high-quality 304 stainless steel, which is not easy to rust, making the machine more durable. Each machine only needs 1-2 people to operate, which can greatly save labor costs for customers and improve work efficiency.

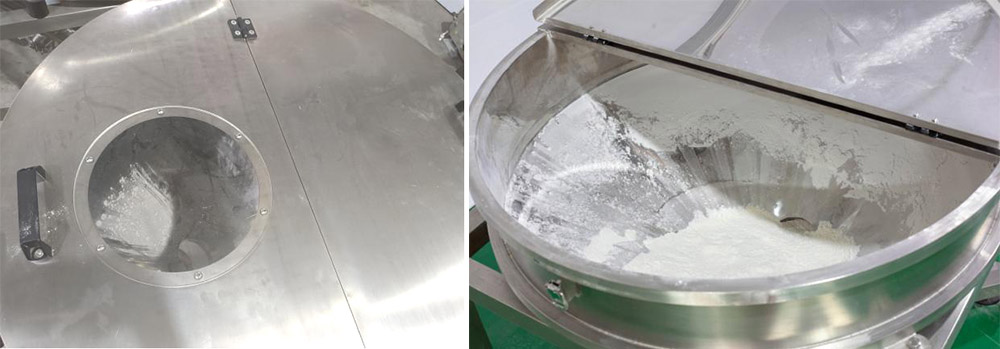

This is the storage hopper of our screw feeder. The worker only needs to pour the powder into this hopper, run the machine, and the screw will automatically transport the powder to the next process. We also designed a cover, the worker needs to close the cover after pouring the powder, which can keep the powder clean.There is a transparent glass port on the cover, which is convenient for workers to observe the material condition at any time and replenish the material in time

We generally use screw measurement for packaging powder. The next process is to use the screw to measure the powder transported by the screw feeder and then drop it for packaging. The accuracy of the screw measurement is about 1%, and the work is also carried out in a closed space. Helps keep the powder and the environment clean.

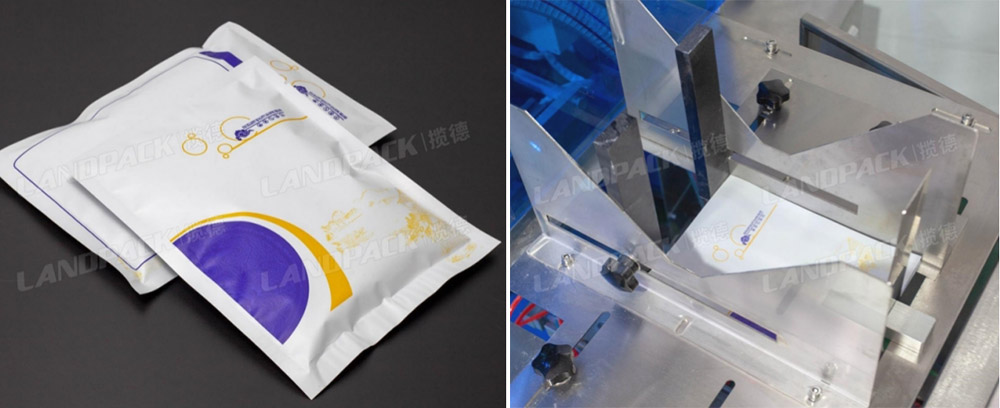

Above is the placement position of the pre-made bag and the finished product display. The pre-made bag placement area can be adjusted according to the size of the bag. After adjusting, the pre-made bags need to be placed neatly. When the machine is turned on,the manipulator will automatically take the bag and put it in a fixed position for opening, falling material and heat sealing, After these, a packet of flour packaged in a clean environment is ready.