If you don't know much about the machinery industry, please read this article carefully. If you want to know about the weighing filling machine, you should read this article. The so-called weighing filling machine must be a large filling machine. Dosage products. The weighing and filling machine products that everyone knows are the barreled bean paste, paint, industrial oil and other paste and liquid products. Because lubricating oil and engine oil are widely used in weighing and filling machines Today we take the lubricating oil weighing filling machine as an example to describe an unusual weighing filling machine.

Principle: The weighing filling machine uses the high measurement accuracy of the electronic scale to connect the electronic weight signal sensor and the weighing control instrument with a data line. During the measurement process, the pressure signal of the electronic scale is continuously transmitted to the control instrument. When the preset quantitative weight is reached, the control instrument controls to stop the pump and close the pneumatic valve.

Workflow: manual bottle feeding---automatic bottle detection---bottling nozzle drop---quantitative filling machine---manual release and modification-automatic capping

Features:

1. The weighing filling machine adopts the filling head of anti-drip and wire drawing, the filling and lifting system of anti-high foam products, the positioning system and the liquid level control system to ensure the positioning of the bottle mouth.

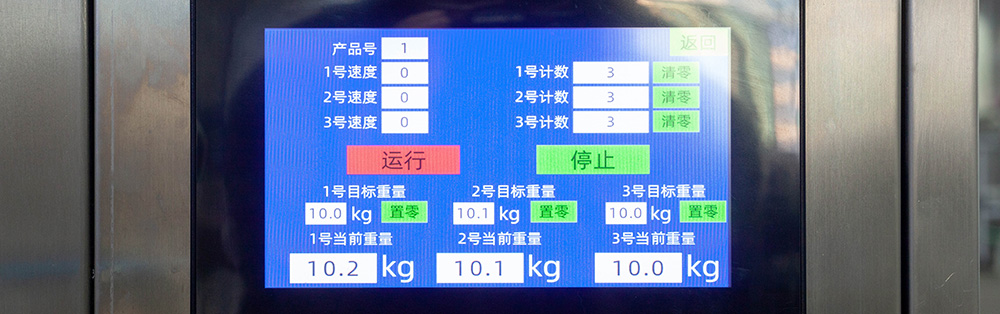

2. The degree of automation is high, and the measurement adjustment is realized in the touch screen, and the operation is reliable. The application of touch screen technology makes the operation of the machine more reliable and convenient, and the man-machine interface is more friendly.

3. Photoelectric sensors, proximity switches, etc. all use foreign brands, so that the mechanical and electrical integration of the machine has achieved excellent performance.

4. The net weight/gross weight is optional, and the weighing value will automatically display "or become a big selling point". With automatic detection, container positioning function, no container filling;

5. Adopt weighing type quantitative filling, with single-cylinder measurement and fine-tuning function;

6. The production speed of this machine is fast, and the specification replacement is convenient; all contact parts of materials are made of high-quality stainless steel, which is an ideal Filling Machine for the pharmaceutical & chemical industries.

Precautions for weighing filling:

1. Do not install in direct sunlight, especially the control instrument part, and avoid sudden temperature changes and strong mechanical vibration;

2. When the temperature is about 20℃ and the relative humidity is about 50%, the instrument is in the best working condition;

3. It is strictly forbidden to connect the ground wire of this equipment with the ground wires of other equipment;

4. The ground terminal of the meter must be reliably connected to the ground, otherwise the meter reading may be unstable;

5. Always observe the liquid level of the oil storage tank. When the liquid level exceeds 2/3, please open the oil release valve in time to drain the oil. After the oil is drained, please close the oil drain valve.

6. Do not touch the weighing tray with the side of the machine;

7. The level of the weighing tray should be adjusted; when filling, the oil nozzle should not touch the barrel wall.

The weighing type liquid quantitative filling machine adopts high-precision electronic weighing technology, combined with automatic filling technology, so as to achieve high-precision dynamic measurement and filling of liquid media, and its measurement accuracy is not affected by pressure, temperature, bubbles and other factors. It is easy to install and debug, easy to use and maintain, and can be used for quantitative filling of edible oil, lubricating oil, alcohol, beverage, building materials, chemical industry and other industries.

In the area of the flood of weighing filling machines, Foshan Lande Packaging Machinery Co., Ltd. is the pioneer of the industry in the research and development and production of weighing filling machines with outstanding characteristics and production capacity. It serves large and small Thousands of small businesses. The weighing filling machine is the representative of the production development and progress of the times, and it is also a turning point in the production of economic progress.