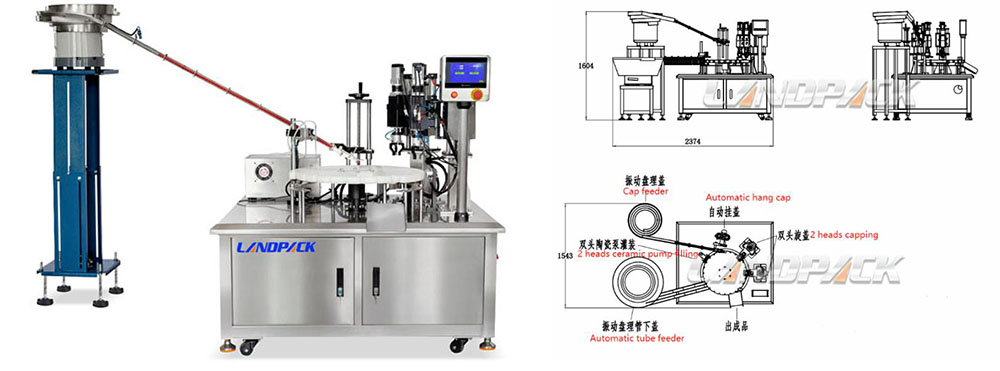

Two heads teat tube filling capping machine:

1. This production line adopts automation technology, Japan Panasonic PLC, imported detection electric eye, frequency converter and other electrical and pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability and good stability, so it has been unanimously praised by the majority of users;

2. This machine adopts 2 heads filling, automatic inner cap feeder, and automatic outer cap feeder and capping an integrated machine;

3. It adopts special hose for food and does not contain plasticizer, which is suitable for medicine, food and other industries;

4. The production line has stable operation, low noise, convenient maintenance, and fully meets the requirements of GMP certification, and is widely used in medicine, food, daily chemical and other industries;

5. The whole machine is made of corrosion-resistant stainless steel, which is convenient for cleaning and disinfection, and meets the national regulations and requirements on food machinery and food hygiene;

6. The production line adopts imported sensors, and the position control is accurate;

7. Using Japanese Panasonic PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

8. This type of production line is relatively advanced, and can be improved according to different requirements of customers, and can be made into equipment that fully meets customer needs.

Feature:

◆This capcity is about 1200-1800tube/minute,Can effectively improve your current production capacity

◆Cap set the packing speed in the touch screen directly.

◆No need to worry that our worker put the tube speed can't keep up with the speed of our machine filling,Before filling, our machine has a bottle sensor, which can automatically identify, no bottle no filling.

◆Our machine can also counting how many test tubes are filled in one day, also can reset the number to zero and count again every day, which is convenient for you to observe the production quantity.

| Touch screen | Intelligent touch screen, perfect system, simple operation.Cap set the packing speed in the touch screen directly. |

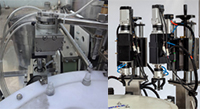

| 2 high purity ceramic pump filling heads | Automatic intelligent identification, if there is no bottle or the material is insufficient, the filling will not be carried out;Control the injection volume of each circle by adjusting the pump head angle, with extremely high metering progress and repeatability.It is specialize for chemical liquid |

| Automatic hang cap and screw capping | Automatic intelligent identification, if there is no bottle no hang cap no capping. |

| Automatic cap feeder device | Just pour the tube into the vibrating plate, the machine will automatically arrange the tube one by one take out |

Why choose us?

1. Our factory has over 15 years experience in filling capping machine area, very professional;

2. We can make customized machine according to customer's requirements and the tube and cap sample.

3. We have a professional team of engineers who can provide stable after-sales service.

4. We have a professional team of engineers who can independently develop machines and update machine quality

5. We offer the best price for machine.