Tips On Selecting An Automatic Liquid Filling Machine

1. Exactly what is an "automatic liquid filling machine"?

According to the filling principle ,they are three major categories,for example:Equivalent pressure filling machine, negative pressure filling machine, and vacuum liquid filling machine.Common equivalent pressure filling machine:they are piston filler and gravity filler.

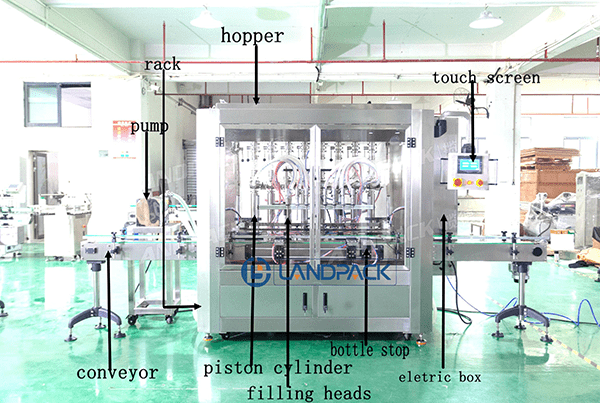

2. what is piston filler?(picture for reference)

When the compressed air enters the upper end of the cylinder, the cylinder moves downward, the piston in the material pipe connected to the cylinder is synchronized down, the material is sucked into the material pipe through the inlet check valve; the piston moves to the set stroke, through the solenoid valve, the material is stopped, the inlet check valve is closed, and the material is pressed into the filling head to achieve quantitative filling.Because the filling cylinder inlet and outlet ports are equipped with a one-way throttle valve, the filling speed can be adjusted according to the needs of the material viscosity.This method can be used for filling sauce,cream,oil,honey,jam,lotion,shampoo,detergent,gel etc.

3. what is gravity filler? (picture for reference)

Under constant pressure, the liquid material flows into the packaging container by heavy weight.Most air-free liquid materials can be filled with this method, such as liquor, fruit wine, milk, soy sauce, vinegar, etc.

4. Liquid filling machine chief component

1.machine rack (304 stainless steel)

2.material hopper

3. Filling head (2,4,6,8,10,12 etc)

4.piston cylinder block and power system (cylinder, frequency conversion motor, servo motor).But gravity filler does not have piston cylinders.

5.electric box

6.Operating Panel

7.conveyor line

5. Liquid filling machine running process

When the automatic filling is opened, the filling bottle is moved on the conveyor belt, through photoelectric detection, photoelectric detected enough bottles, the machine will automatically carry out a series of procedures, and the filling after all the bottles are in place.When the filling amount reaches the predetermined value, the filling stops, the bottle blocking mechanism takes back, the filled bottle is removed, and the working process begins at the bottle ahead.

6. What is the machine filling range?

Standard filling machines usually fill 50-1000 ml.If you have bigger or smaller filling volume,we can customized the machine according to your products.

7. Applicable container of liquid filling machine plastic bottles, glass bottles, jars,cans, iron cans, aluminum cans, etc.

8. How to select the most appropriate automatic liquid filling machine?

8.1According to material properties,if you have a very viscous very fluid or very poor flow,you should choose a piston liquid filling machine.If your liquid flow is very good,gravity filler would be the best recommendation.

8.2According production requirements,if you have a high speed requirements,normally you should choose the filling machine with more heads.(In addition,there are other customized filling machine according to your requirements also).

8.3According to your budget,if your budget is not high,you can buy a small number of fillers to start production.

9. If my products are both high viscous and non viscous,what filling machine should I choose?

In this case,the piston liquid filling machine will be the most suitable choice.It can be used to fill not only non-liquid products,such as jam,but also water.

10. Can I trust your solution?

We have a professional technical research and development tam ,and we have 20 years of industry experience.Buying filling machine ,choosing us!

Previous: What is automatic labeling machine?

Next: None