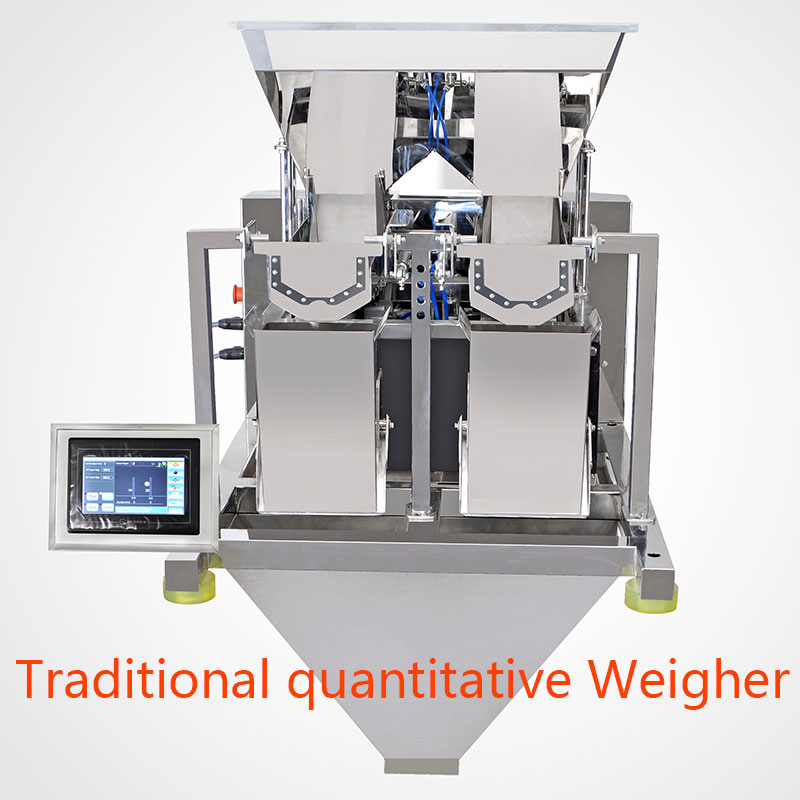

With the rapid development of modern industry, the packaging industry also has higher requirements in terms of packaging accuracy, packaging speed, packaging range, etc. It is difficult for traditional quantitative automatic packaging scales to meet these requirements, and computer combination scales are here developed under the requirements, it has the following differences from traditional quantitative automatic packaging scales:

1. Differences in weighing accuracy caused by different weighing principles

① Different weighing principles

The quantitative automatic packaging scale weighs and adds materials at the same time, and continues to feed materials before reaching the target weight data. When there is a slight difference from the target weight, an additional object needs to be weighed must be added, which means that rough measurement is followed by precise measurement. If the object to be weighed is larger in size, Or when it is heavier, there will be a larger error, which affects its weighing accuracy. The computer combination scale is composed of multiple weighing units with independent feeding and discharging structures. Generally, the computer combination scale is composed of 8 to 32 weighing units. The computer uses the principle of permutation and combination to automatically calculate the optimal combination of load capacity of each weighing unit and obtains the best and closest combination to the quantitative value for packaging. For example, a computer combination scale with ten weighing units. When weighing, each weighing unit is weighed, and the weight data of each weighing bucket is read into the computer. The computer performs the optimal combination. According to combination mathematics, ten weighing units can achieve a total of 1023 combinations, and the computer selects the combination closest to the target weight value from these 1023 combinations. In this way, the problem that the weight of the object to be weighed is relatively large and it is difficult to achieve a quantitative value during the above-mentioned precise measurement and weighing is easily solved. Computerized combination scales use the combination closest to the target weight as the final result.

② The reliability of detection data is different

Since the traditional quantitative automatic packaging scale weighs while adding materials, the sensor is weighing under dynamic conditions. If the object being weighed is impacted or jumped, the sensor will sense unstable weight data and cause errors. Computer combination scales The vibration feeding is carried out to the buffer hopper, and the weighing of the weighing hopper is carried out under stable conditions, so the weight data obtained is more accurate.

③ Drop error

This error is a very significant error for quantitative automatic packaging scales. When the weight value in the weighing hopper reaches the set value, although the electromagnetic vibration feeder has stopped, the moment it stops, the section from the weighing hopper to the vibrator is The existence of scaled objects will eventually fall into the bucket, resulting in the so-called drop error. Although some quantitative automatic packaging scales reduce the drop error by shortening the feeding time, due to the influence of system uncertainties such as flow rate and feeding uniformity, There are still varying degrees of error. The computer combination scale supplies materials from the buffer hopper to the weighing hopper. After the weighing hopper is completely stable, it issues an instruction to weigh, so there is no drop error.

2. The difference between weighing speeds

Traditional quantitative automatic packaging scales generally go through the weighing process of rough measurement and fine measurement. In particular, the fine measurement process requires additions little by little, which takes a long time and affects the weighing speed. For example, the weighing speed of quantitative automatic packaging scales under 1 kilogram is generally 20 to 30 packages/minute, while computer combination scales can generally reach 100 to 120 packages/minute with 14 weighing units through the computer's fast optimal combination operation. The weighing speed is 4 to 6 times faster than the quantitative automatic packaging scale, and it is easy to cooperate with various packaging machines. It greatly improves packaging efficiency and is more suitable for the needs of modern production management.

3. The difference between weighing ranges

When the accuracy is the same, the weighing range of the computer combination scale is larger than that of the quantitative automatic packaging scale. Generally, the weighing range of the quantitative automatic packaging scale is controlled within 4 times with the same accuracy, while the computer combination scale has a smaller weighing range. The weighing range of the segment can reach more than ten times. It can also be seen from a large number of test results that there is a difference in weighing range between the two. For example, in the weighing range from a dozen grams to 1 kilogram, a computerized combination scale can meet the accuracy level requirements of X (1) level, which is especially rare in small weighing sections. If you want to keep the accuracy level unchanged, the quantitative automatic packaging scale can only reduce the weighing range and form multi-stage weighing. Only by producing multiple series of products can the manufacturer's requirements in a certain aspect be achieved. Most manufacturers would hardly accept this phenomenon. This brings limitations to its practical application, and it cannot meet the usage requirements of different packaging specifications (10-1000g) but similar accuracy in some production fields.

The advantages of computer combination scales are clear at a glance. However, in the past, computer combination scales were mainly produced by imported or foreign-funded enterprises. Therefore, price issues hindered their widespread application. Now Foshan Land Packaging Machinery Co., Ltd. provides advanced computer combination scales with stable performance, honest after-sales service, and prices closer to domestic food terminals, which have won the favor and respect of a large number of food manufacturers. LandPack combination scale makes the computer combination scale, which was originally regarded as an "aristocratic product", no longer listed as the patent of large enterprises. More domestic enterprises pursuing high speed and high efficiency have eliminated the previous cup-containing type or all labor-intensive materials. The labor-intensive quantitative weighing and packaging production line is equipped with a high-tech and more automated combination scale quantitative weighing and packaging system. The early localization of computerized combination scales is not only a great boon for Chinese food companies, but it is also the biggest weight in promoting the popularization of quantitative weighing and packaging systems in domestic production.

4.The Specification of LandPack Multi Head Weigher:

| Model | LD-14 | LD-16 | LD-12 | LD-10 | LD-8 |

| Number of weighing heads | 14 | 16 | 12 | 10 | 8 |

| Per weighing range | 10-2000g | 10-1000G | |||

| Weighing Accuracy | ±0.3-1.5g | ±0.3-1.5g | ±0.3-1.5g | ±0.3-1.5g | ±0.3-1.5g |

| Weighing Speed | 120bag/min | 180bag/min | 100bag/min | 70bag/min | 60bag/min |

| Hopper capacity | 1300ml | 1300ml | 1700ml | 1300ml | 1300ml |

| Hopper type | Double-row unrecorded bucket | Double-row unrecorded bucket | single row bucket | Double-row unrecorded bucket | Double-row unrecorded bucket |

| Product default mode | 99 modes | ||||

| Control element | 10.4-inch LCD aiming screen | ||||

5.Packing Solution For Banana Chips From LandPack: