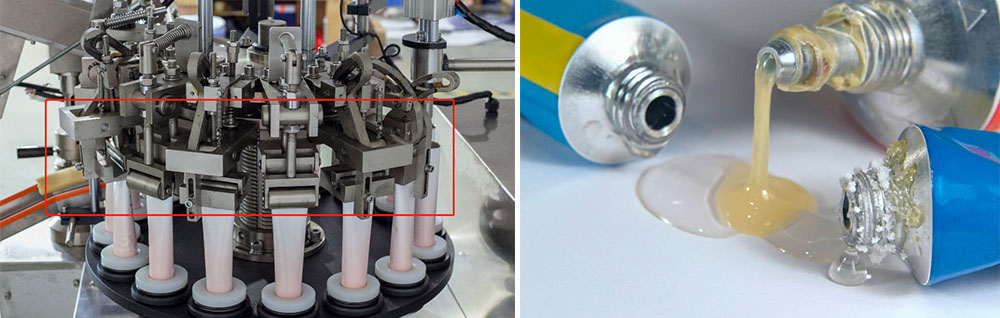

Aluminum tube filling sealing machine is mainly used aluminum tube as packaging container. It’s widely used in the medicine industry, daily chemical, food industry. Filling and sealing liquid or paste materials such as ointment, toothpaste, epoxy glue, 502 glue, hair dye, etc.

The working principle

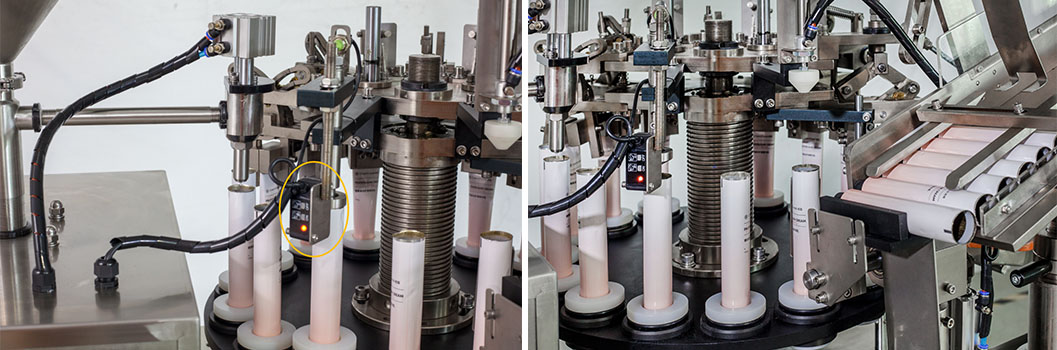

Automatically or manually insert the empty metal tube into the tube holder, Total 16 working station. Each Station has tube holder to fix the metal tube. With mechanical control system to rotate the rotary plate and finish all other process. One tube size, one set of holder was request. Acceptable diameter for the metal tube can be range from 15mm~38mm.

A photoelectric sensor will be install on second working station to confirm that there is a tube coming and to position it facing right direction. Before moving forward to other working station.

the next step is to automatically meter and filling the liquid into the metal tube, range can be 20~200ml by one same machine.

The following process if for folding and cutting into the ideal shape. Some customer prefer 2folding, while other customer prefer 3 folding.

could install or dis-assembling the folding and pressing station base on customers need. That means, one machine can do both 2 folding or 3 folding tube Style, and then cutting and output the finished tube.

But Still some customer would ask: But under what circumstances should we choose an aluminum tube filling machine?

Land Packaging Machinery has been in the packaging industry for over 15 years. We’ve custom-made hundreds of different cases to help our customers start their business and increase their production smoothly.

If you should choose aluminum tube filling machine or not, it depends on the following factors:

1. Your product characteristics (viscosity, foaming), filling capacity, tube shape and productivity, and budget.

2. No matter your are small and medium-sized enterprises, or foreign enterprises, if you have large variety of products, and each of them just very small batches each time, and you may consider relatively low investment, then semi-automatic aluminum tube filling and machine is a practical choice. Currently, this is selling well in Guangdong China, where cosmetics manufacturers are most concentrated.

3. For enterprises with many product varieties but large batches, we’d suggest you to combine semi-automatic and automatic aluminum tube filling and sealing machine. To save labor cost

4. For newly established enterprises, when even the product range is narrow, you may have want to get a low invest high output machine, in this case you can choose an automatic aluminum tube filling and sealing machine. Actually cost is not so big different between semi-auto and full-auto machine. And fully automatic one will really help you save lots of labor cost.

5. Another important factor affecting the choice of model of aluminum tube filling and sealing machine is often related to the experience, habits and investment decisions of business operators.

Any confused, no hesitate to Contact Us, get more information!