What is automatic labeling machine?

A manufacturer provides clever engineering and flexible solutions for every requirement.

The entire LANDPACK team is ready to help customers overcome various challenges. This makes us the most popular professional sticker labeling machine manufacturer in many industries and applications.

Which series is LANDPACK popular labeling machine?

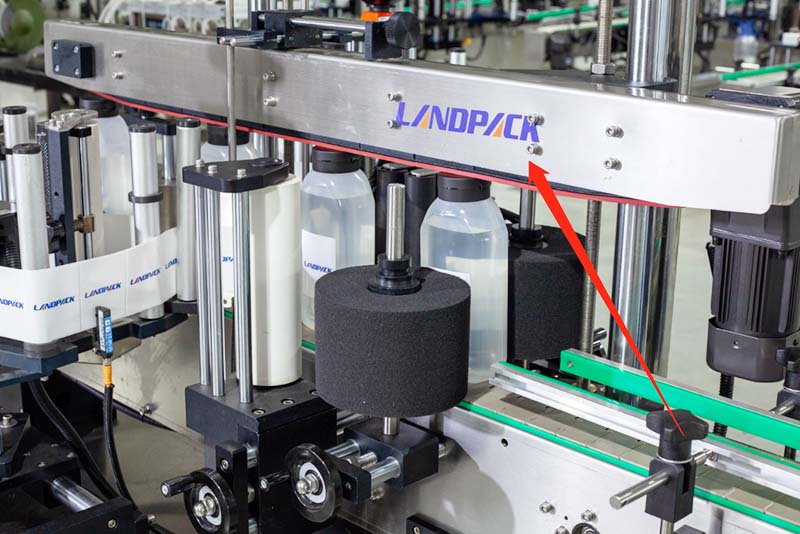

Our LD-SM-00 Double side labeling is one of our full automatic labeling machines.It’s suitable for the round bottle,square bottle ect.

Product description:

Suitable for square bottle single side and double sides labeling.It equipped with round bottle labeling machanism,can be used for positioning round bottle,square bottle and other shaped bottle,greatly improve the scope of the equipment application.

Features:

1)Label head application:

a.Multi-dimensional adjustment :Label head can achieve 8-D spatial accurate positioning adjustment.

b.Labeling head lateral translation:Micro -adjustment of labeling machine position can be realized by lateral translation of the label head

c.All the regulating machanisms can realize fast regulation

d.The design of pressure roller is used to improve the tension of the label ,especially for ultra thin label.

e.All structural parts are machined by numerical control,High precision matching of components to ensure accuracy grade of equipment.

f.Label clutch makes machine running more smoothly.Three-point label head up and down adjustment device make the adjustment more easily.

g.The special scrape support is easy to adjust.

2)Belt compression machanism application

a.Main motor gear drive ,increase transmission torque and reduce transmission clearance can affect labeling accuracy.

b.Separate pressure belt pad conducive to heat dissipation.And it can choose different pressure device according to the requirements of different working stations.

c.Large span support with compression belt,double screw adjustment ,synchronous belt drive between screw to realize synchronous adjustment.

d.Increase belt buffer slider can improve its mechanical performance.

e.Wide range height adjustment to facilitate product category replacement,adjustable area 0-400mm

3)Plastic machanism application:

a.Adopt Mechanical transmission.main transmission line,belt compression and plastic belt are used to drive by gear,driven by a powerful motor can realize speed regulation without segment.

b.The use of increased spiral bevel gear drive to improve the safety performance of the operation.

c.Two-dimensional space adjustment to increase the scope of machine application

d.Using the chain of polymer material is beneficial to the accuracy of plastic shaping.

4)Conveyor application:

a.High precision conveyor strip is used to realize the absolute synchronization between the conveyor line

b.The wide strip design and powerful motor drive expand the range of application of the equipment,improve the operational inertia of the transmission line and obtain higher labeling accuracy.

5)Positioning mechanism application

The automatic bottle type correction positioning system is the secondary positioning mechanism applied on the straight line labeling machine,which completely solves the problem of the special shape bottle labeling machine.When special shaped bottles labeling,please make adjustment according to the cross-section characteristics of the attached bottle,so taht all the bottles are fixed up and down to one position,and then the bottles will be sent out at the same line speed as the conveyor line.The position of the positioned abject is accurately positioned between the belt and the delivery line.

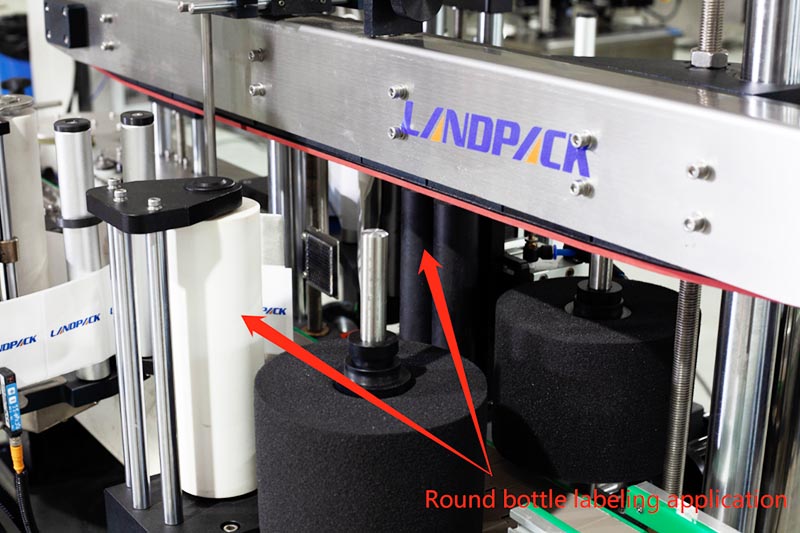

6)Round bottle labeling machanism application

a.Round bottle labeling machamism can achieve bottle positioning to realize high-speed accurate labeling.

b.It can be adjusted and replaced quickly,convenient to change different bottles,shortens changing time and improves production efficiency.