Application:

This liquid bottle filling line can be tailored to handle a wide range of products, making it ideal for filling various daily chemical liquids, such as hand soap, mouthwash, liquid detergent, dish wash, paint, lubricating oil, sanitizer, facial cleanser, face cream, and more.

Packaging Material:

Glass, Metal, Paper, Plastic, Wood, and Others.

Advantage:

The product adopts advanced general control technology by using a PLC touch screen, and intelligent filling to make operation simpler, more convenient, and easier to study, can set the filling amount and filling speed through the touch screen

Kindly Reminder:

Parameters:

| 8 heads gear pump filling machine | |||

| Model | LFZ-08 | ||

| Filling Range | 50-1000ml(Customizable) | ||

| Filling Speed | 30-40 bottles/min | ||

| Measurement accuracy | ±1% | ||

| Power | 3.5 KW | ||

| Working power supply | 220V, 50Hz | ||

| Working pressure | 0.6-0.8MPa | ||

| Weight | 800kg | ||

| Size | L4000*W1320*H2090(mm) | ||

| Autoamtic capping machine | |||

| Model | LFX-JX-01 (Four wheel capping) | LFX-GS-150 (Eight wheel capping) | LFX-GS-250 (Six wheel capping) |

| Capacity | 20-50 bottles/min | 40-100 bottles/min | 30-80 bottles/min |

| Bottle cap diameter | Ф22mm-Ф80mm | Ф18mm-Ф80mm | Ф18mm-Ф80mm |

| Bottle diameter | Ф35mm-Ф140mm | Ф35mm-Ф140mm | Ф35mm-Ф140mm |

| Bottle sealing height | 38mm-300mm | 38mm-300mm | 38mm-300mm |

| Power | 1.5KW | 2KW | 1.5KW |

| Voltage | 220V, 50HZ | 220V, 50HZ | 220V, 50HZ |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.5-0.7Mpa |

| Weight | 250kg | 350kg | 300kg |

| Dimensions | H3000*W800*L1600 mm | H3120*W1544*L2122 mm | H3100*W1244*L2122 mm |

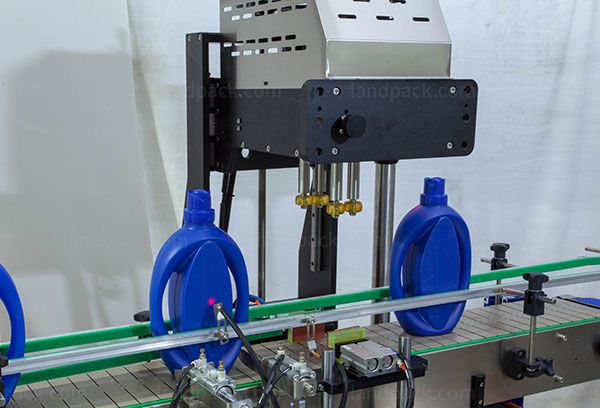

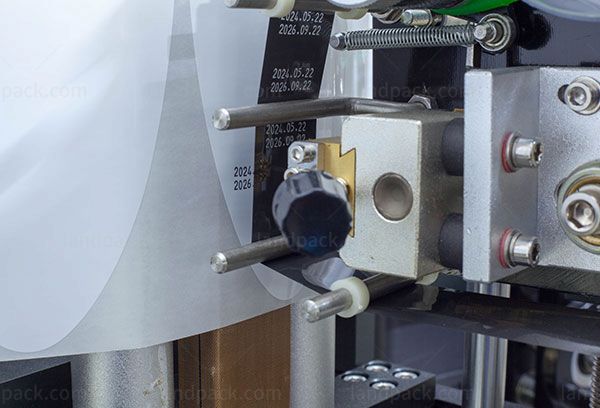

| Automatic double side labeling machine | |||

| Model | LFT-SM-00 | ||

| Labeling Speed | 10-40 bottles/min | ||

| Labeling Accuracy | ±1mm (Does not contain product and label errors) | ||

| Max Label Width | 200 mm | ||

| Applicable Product Size | H≤400mm, T≤100mm (Can be customized) | ||

| Applicable inner diameter of paper | Ф76.2 mm | ||

| Applicable outer diameter of paper | Max.Ф350mm | ||

| Air Source | 4-6KG 30L/min | ||

| Dimension | 3050*1450*1800 mm | ||

| Voltage | 220V 50Hz 3500W | ||

| Weight | 500 KG | ||

Features:

1. Liquid Delivery Pump: Efficiently transfers liquid into the filling hopper, ensuring consistent supply.

2. Precision Gear Pump System: Controlled by a servo motor for accurate liquid dispensing, with an adjustable filling volume.

3. Flexible Capping Solution: Handles a variety of screw caps with easily adjustable capping heads, eliminating the need for additional components.

4. Bottle Detection Sensor: Automatically halts the filling, capping, and labeling processes when no bottle is present, minimizing waste.

5. Integrated Control System: Simplifies machine operation with centralized control, enhancing productivity and ease of use.

Get Price & More Detail