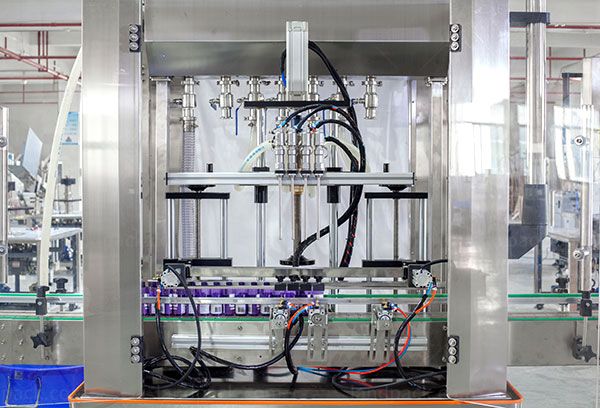

Automatic Piston Viscous Lubricant Filling Machine

Model: LF-LH-04

Application:

It's suitable for the automatic filling of various bottle types in lubricant oil, engine oil, olive oil, oil, lube oil, shampoo, sauce, tomato paste, ketchup, liquid milk, water, honey, juice, etc.

Examples:

Heavy sauces, salsas, salad dressings, cosmetic creams, heavy shampoo, gels, conditioners, paste cleaners and waxes, adhesives, heavy oils, and lubricants.

Application:

It's suitable for the automatic filling of various bottle types in lubricant oil, engine oil, olive oil, oil, lube oil, shampoo, sauce, tomato paste, ketchup, liquid milk, water, honey, juice, etc.

Packaging Type: Bottles, Cans, Tins, Barrel, Capsule, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, Other

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Technical Parameter

| Filling Nozzles | 1-16Nozzles |

| Production Capacity | 800 -5000Bottles Per Hour |

| Filling Volume | 100-500ml,100ml tp 1000ml |

| Power | 2000W, 220VAC |

| Accuracy | ±0.1% |

| Driven | Panasonic Servo Motor |

| Inerface | Schneider Touch Screen |

Products to Fill:

1) hot fill ( 35~40℃), cold filling normal temperature

2) Specific Gravity: 1.1~1.4 gr/m³

3) Spreading Chocolate past • Honey • Spreading Cheese paste, Molasses.

Bottle type:

1) PET bottle • Quadrant Cross section • Volume 250 ml. • neck 32 mm.

2) Glass Jars & PE, PET Jars • Cylindrical Cross section • Volume 200 ~ 350 ml. • neck 45 mm.

Filling tolerances: +/- max 0.5%

Main Structure

1. 20L to 200L Top hopper for option, double Jacket hopper with heating and mixing system for option

2. Main body of the machine made by 304SS

3. Filling nozzles, filling nozzles are specially designed for anti-drop sauce filling

4. Filling nozzles moving up and down by air cylinder, and servo motor moving up and down for the option

5. PLC control system, and HMI operation

6. Especially made horse and valve for honey, with CIP system connecting horse

Competitive Advantage

1. There are many advantages of the automatic piston-filling machine.

2. PLC control, operation on the touch screen.

3. Panasonic servo motor driven, automatically adjust the Filling size on HMI, eg. Users want To fill 500g sauce, users just input the number 500, then the machine will automatically adjust.

4. It is volumetric by a piston, with high filling accuracy.

5. With top Double jacketed heating and mixing tanks.

6. The automatic sauce-filling machine also can have the function of a CIP system which will connect the users' CIP system.

7. The horse of the sauce filler is specially made according to the sauce's nature, with no dead corners, and food grade.

8. Specially made rotary valve for viscous sauce transfer.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail