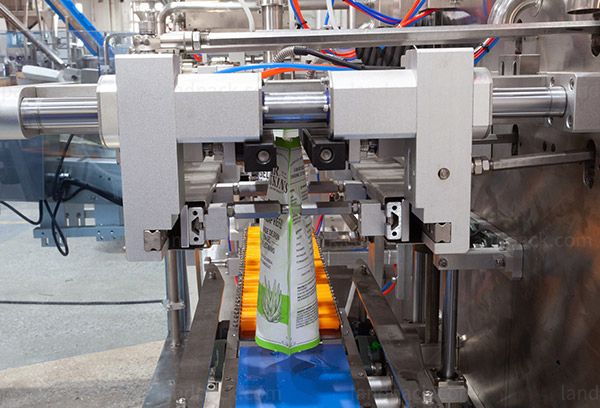

Automatic 2 Heads Mayonnaise Packing Machine Premade Bag Sauce Doypack Packing Machine

Model : LDSP-260L

Application :

This doypack machine with 2 filling heads is suitable for filling mayonnaise, sauces, peanut butter, ketchup, egg white, jam, chili sauce, lotus seed paste, bean paste and other food stuffing as well as drinks of large bulk. Suitable pouch: premade pouch; zipper pouch; stand-up pouch; spout pouch.

Application :

This doypack machine with 2 filling heads, it can automatically complete bag feeding, filling, sealing, coding and other functions.

Examples :

Mayonnaise, sauces, peanut butter, ketchup, egg white, jam, chili sauce, lotus seed paste, bean paste and other food stuffing.

Bags Style :

Premade pouch, zipper pouch, stand-up pouch, spout pouch;

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

1. Dual Filling Nozzles – Fill simultaneously to achieve the target volume; each nozzle is independently adjustable, reducing filling time and increasing packaging speed.

2. High Filling Accuracy & Easy Operation – ±1% filling accuracy with user-friendly controls.

3. Applicable Bag Size – Supports 120-260 mm (W) × 110-360 mm (L).

4. Bag Support Device – Prevents bag slippage due to heavy filling weight, ensuring proper sealing position and quality.

5. Siemens PLC & Display Screen – Ensures reliable control and user-friendly operation

6. Horizontal Bag Giving Device – Optimized for spout bags, ensuring successful automatic bag picking.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail