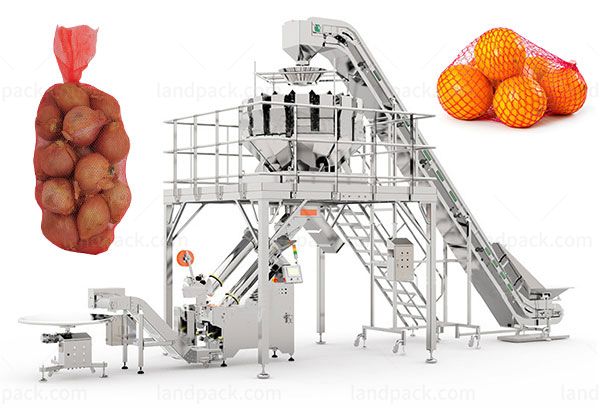

Automatic Orange Fruit Vegetable Net Bag Mesh Bag Weighing Packaging Labeling Machine

Model : LD-MB01

Introduction :

The mesh bag packaging equipment operates at a maximum speed of 40 bags per minute, depending on the packaged product. The actual packaging speed may vary based on the specific characteristics of the product.

Application :

This machine is perfect for sealing continuous mesh bags for a wide range of products, including fruits, vegetables, and other items. It ensures secure and efficient packaging for various applications.

Examples :

Fruits, vegetables, and other items. It works well with oranges, apples, tomatoes, onions, garlic, bell peppers, sweet potatoes, potatoes, shellfish, jelly, and even non-food products like LEGO bricks.

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers :

| Model | LD-MB01 |

| Bag Material | Plastic |

| Bag Type | Mesh bag, net bag |

| Size Range | 80mm≤W≤300mm, 100mm≤L≤400mm |

| Speed | 30-40 bags/min |

| Voltage | 220V, Single-phase, 50/60HZ, 1.2KW |

| Air Pressure | 0.65Mpa |

| Air Consumption | 0.3m³/min (Standard machine, no additional function) |

| Body Dimension | 1950*1010*2010mm |

1. High-Efficiency Inclined Conveyor: Effectively transports fruits and vegetables to the weighing system, saving space and optimizing workflow.

2. Precision Multi-Head Weigher: Delivers fast, accurate weighing to ensure consistency and minimize errors in packaging.

3. Automatic Discharge System: Transfers products seamlessly from the weighing station to the mesh bag packing conveyor for continuous operation.

4. Integrated Labeling and Date Printing: Features a tap labeling system with built-in date printing for clear product identification and traceability.

5. User-Friendly Design: Streamlines the entire packing process, reducing manual effort and increasing overall production efficiency.

6. Flexible Packaging Capabilities: Accommodates various bag sizes and products, offering adaptable solutions for diverse packaging needs.

Working Process:

The workflow is as follows: First, products are manually sorted and placed on the conveyor belt. The conveyor then moves the materials to multi-head weigher and then fills them to the net bag packing machine via a lift conveyor. During the automatic packaging process, the set label is printed automatically. Finally, manual framing is conducted to complete the standardized packaging of the products, ensuring efficiency and precision.

We have many customer packaging & filling case videos, please feel free to contact us to obtain your product packaging & filling case videos.

Get Price & More Detail