Automatic Milk Powder Bottle Filling Machine Line Protein Powder Filling Production Line

Model : LFPD-50-30

Application :

This machine is commonly used for bottle filling, capping, and labeling across various industries such as pharmaceuticals, food, cosmetics, and chemicals. It is ideal for products like milk powder, protein powder, medicinal powder, spices, talcum powder, coffee powder, meal replacement powder, and chemical powder, ensuring precise and efficient packaging.

Application :

This machine is commonly used for bottle filling, capping, and labeling across various industries such as pharmaceuticals, food, cosmetics, and chemicals.

Examples :

Milk powder, protein powder, medicinal powder, spices, talcum powder, coffee powder, meal replacement powder, and chemical powder, etc.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

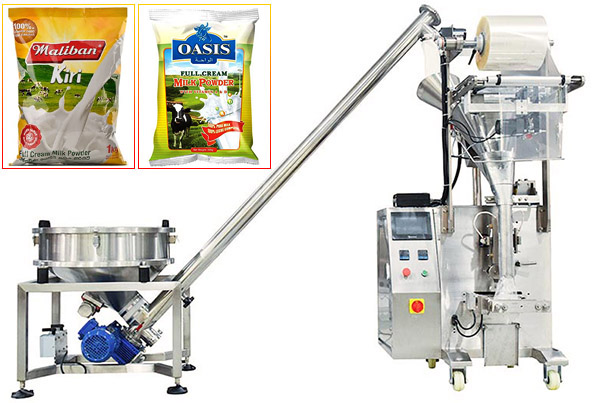

Packaging Samples :

| Bottle Conveyor Feeding Device | |||

| Power Supply | 220V/110V, 50-60Hz, 200W | ||

| Turntable Diameter | 1000mm(Could be customized) | ||

| Suitable Bottle Diameter | 20-450mm | ||

| Suitable Bottle Height | 30-450mm | ||

| Working Speed | 40-60bottles/min (Could be customized) | ||

| Package Size | 1230*1010*1260mm (Could be customized) | ||

| Gross Weight | 256kg | ||

| Automatic powder weighing filling machine | |||

| Mode | LFP-01 (Single Head Powder Filling) | LFP-01 (Single Head Powder Filling) | LFPD-50-30 (Double Head Powder Filling) |

| Filling Weight | 10-5000g (Replace screw specifications) | 10-5000g (Replace screw specifications) | 100-2000g |

| Bottle diameter | Φ30-Φ140mm (Could be customized) | Φ30-Φ140mm (Could be customized) | Φ60-Φ135m |

| Bottle Height | 50mm-200mm (Could be customized) | 50mm-200mm (Could be customized) | 601-260mm |

| Capacity | 10-20 bottles/min | 20-40 bottles/min | 10-25 bottles/min |

| Measure accuracy | ≤500g, ≤±1%; ≥500g, ≤±0.5% | ≤500g, ≤±1%; ≥500g, ≤±0.5% | 100-1000g, ≤±2g; ≥1000g, ≤±5g |

| Power | 2.5KW | 5KW | 4.5KW |

| Capping Machine | |||

| Model | LDBZ-C (Single heads servo capping) | LDBZ-2C (Double head servo capping) | LDBZ-3C (Three heads servo capping) |

| Capacity | 30 bottles/min | 40 bottles/min | 50 bottles/min |

| Bottle diameter | Φ25mm-Φ100mm (Could be customized) | ||

| Bottle sealing height | 40mm-200mm (Could be customized) | ||

| Power | 2KW | 2.5KW | 3KW |

| Voltage | 220V, 50HZ | ||

| Air pressure | 0.4-0.6Mpa | 0.5-0.7Mpa | 0.7-0.9Mpa |

| Weight | 300kg | 350kg | 400kg |

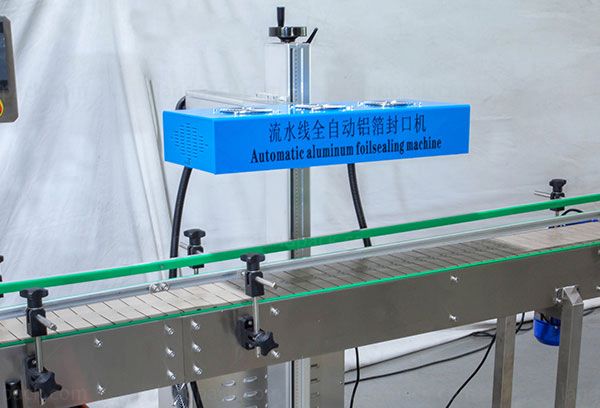

| Automatic Aluminum Foil Sealing Machine | |||

| Model | LD-ZS(Double Heads Aluminum Foil Sealing) | LF-LB-2000(Single Heads Aluminum Foil Sealing) | |

| Applicable bottle diameter | Φ10-200mm (Could be customized) | ||

| Applicable bottle height | H:40-300mm(Could be customized) | ||

| Speed | 0-30bottle/min | 0-10bottle/min | |

| Bottle material | Glass, ceramics, plastics, metals | ||

| Voltage | 220V,50HZ | ||

| Power | 1500W | 1200W | |

| Dimension | 1500*800*1750mm | 1200*600*1550mm | |

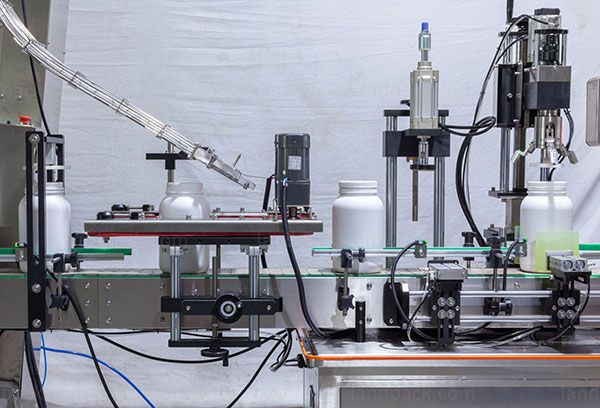

| Automatic Labeling Machine | |||

| Model | LFT-LG-100(Low speed labeling) | LFT-GS-100(High speed labeling) | |

| Label length | 20mm~300mm | ||

| Label width/height | 20mm~200mm(can be customized) | ||

| Bottle width | 30-150mm(can be customized) | ||

| Roll Label outer diameter | 300mm | ||

| Roll Label inner diameter | 76mm | ||

| Accuracy | ±1mm | ||

| Label speed | 40-100pcs/min | 60-120pcs/min | |

| Conveyor speed | 5~25m/min | 15~20m/min | |

| Suitable label type | Adhesive sticker label(transparent label need customized) | ||

| Working air pressure | 0.4-0.6Mpa | ||

| Voltage | 220V can be customized 4KW | ||

| Weight | 350KG | 450KG | |

| Overall dimension | 3000mm×1450mm×1950mm | 3050mm×1550mm×1950mm | |

1. Stainless Steel Construction (SS304): Ensures a hygienic and safe design, perfect for food-grade applications.

2. Fully Automated Filling Process: Reduces labor costs while maintaining high safety and hygiene standards.

3. Dual Auger Screw System: Provides precise weighing and filling with high accuracy through a secondary measurement system.

4. Adjustable Bottle Compatibility: Easily accommodates a range of bottle sizes with stable and reliable performance.

5. Clear Coding and Attractive Labeling: Ensures accurate date printing and professional packaging with a seamless labeling and sealing process.

6. User-Friendly Operation: Simple to operate, minimizing training requirements and ensuring ease of maintenance.

7. High Efficiency and Consistency: Designed for continuous, precise filling, increasing overall production efficiency.

We have many different kinds of powder customer packing case videos, please feel free to contact us to obtain your product packing case videos.

Get Price & More Detail