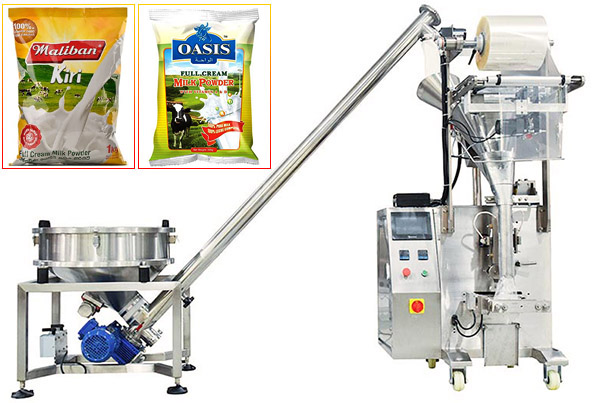

Automatic Milk Powder Can Tin Filling Seaming Production Line

Model : LD-PAF01

Application :

It is perfect for filling various powdered products, including milk powder, protein powder, coffee powder, meal replacement powder, chemical powder, medicine powder, and more. The system ensures precise and efficient packaging for a diverse range of powdered goods.

Application :

This milk powder can filling and seaming line is extensively used in industries such as pharmaceuticals, food, cosmetics, and chemicals.

Examples :

Milk powder, protein powder, coffee powder, meal replacement powder, chemical powder, medicine powder, and more.

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Exambers :

| UV Cleaning Blowing Machine | |

| Item | Specifications |

| Voltage | 220V/50Hz (customized) |

| Power | 2500W |

| Air pressure | 0.3-0.5mpa |

| Speed | 10-50 BPM |

| Bottle diameter | 76-140mm |

| Bottle high | 80-200mm |

| UV light | 7 |

| Outline dimension | 2400*1300*2200MM |

| Net weight | 350KG |

| Spoons vibration feeder | |

| Voltage | 220V/50Hz (customized) |

| Power | 300W |

| Speed | 10-40 BPM |

| Vibration top diameter | 60-80cm |

| Spoon size | customized |

| Outline dimension | 1000*800*1200MM |

| Net weight | 150KG |

| Auger Filler (powder dosing) | |

| Max Weight | 10~1000g/time |

| Container size | Φ 80-210mm H100-330mm(customized) |

| Filling weight | 900g-2500g(customized) |

| Filling accuracy | 500g,≤±1% |

| Filling speed | 10~30bottles/min(depend on the material and weight) |

| Auger Filler hopper | 50L |

| Power supply | Three phase380V or single phase |

| Total power | 3.5 KW |

| Total weight | 420kg |

| Dimension | 2000*900*1850mm |

| Automatic Can Seamer Machine | |

| Bottle type | round, square bottles, etc need to be customized. |

| Can body max diameter | 153mm(can be customized) |

| Bottle height | 50-150mm(can be customized) |

| Speed | 5-8BPM(it depends on product) |

| Seaming Type | Nitrogen consumption and vacuum seaming |

| Caps feeding type | Automatic lids feeding |

| Machine voltage | 220V(can be customized) |

| Machine size | 2000*1000*1700mm |

| Machine weight | 550kg |

| Laser Printer | |

| power | 20~200W (can be option) |

| Laser | 1064mm |

| repeat frequency | 20~200KHZ |

| basement membrane Gaussian beam | <1.2 |

| Printing range | 100*100mm |

| Engraving | <0.4mm |

| Speed | Max 10000mm/s |

| Minimum Line Width | 0.01mm |

| Minimum character | 0.15mm |

| Accuracy | ±0.02 |

| Power supply | 220V/50Hz, 500W |

| Positioning way | Infrared focusing |

| Machine size | 825*545*1425mm |

| Machine Weight | 60kg |

| Operating system | Embedded touch marking system or external 10.1 inch |

| Cooling method | Built-in air cooling |

| Control interface | Standard USB |

| File format | All fonts/glyphs of WINDOWS operating system fonts |

| Laser type | Air-cooled fiber laser; Service life of up to 100,000 hours |

| Automatic Cans cleaning machine | |

| Speed | 20-40bpm |

| Bottle diameter | 80-210mm (or custom-made) |

| Power | 2KW 380V |

| Weight | 350KG |

| Machine size | 1700*800*1800mm |

| Automatic lids pressing machine | |

| Material | 304 stainless steel |

| Cover size | Cover diameter: 40-130mm (can be custom-made) |

| cover height | 5-15mm |

| Bottle diameter | 50-220mm |

| Speed | 10-50 bottles/minute |

| Conveyor belt size | (L)1900mm*(H)900*(W)114mm |

| Machine size | (L)1900mm*(H)1700*(W)800mm |

| Weight | 250KG |

| Power | 220V, 50HZ, 0.68KW |

| Air pressure | 0.5-0.7MPa, require 750W air compressor |

1.Fully Automated Packing System: Reduces labor requirements while boosting operational efficiency.

2.Dual-Head Auger Filler with Precision Weighing: Delivers exceptional accuracy in filling, ensuring consistent product quality.

3.Vacuum Sealing and Nitrogen Flush System: Maintains low oxygen levels, below 3%, to preserve product freshness and extend shelf life.

Workflow:

1. Full Automatic Empty Can Feeding Machine

2. UV Sterilization Machine

3. Automatic Spoon Feeding Vibrator

4. Double Heads Auger Filler with Weighing Sensor

5. Vaccum Seaming and Nitrogen Filling Machine

6. Fiber Laser Printer

7. Filp Device

8. Finish Can Cleaning Machine

9. Full Automatic Lid Pressing Machine

10. Finished Can Collection Machine

We have many different kinds of powder customer packing case videos, please feel free to contact us to obtain your product packing case videos.

Get Price & More Detail