Automatic Milk Powder Tin Can Filling And Sealing Machine

Model: LF-PJ-06

Application:

Automatic milk powder tin can filling and sealing machine (LF-PJ-06), it is Designed for Tin Can metering filling and sealing, suitable for various kinds of powder and granular products into bottles/cans, such as, Milk powder, Chinese / Western medicine powder, food powder and chemical powder etc.

Package weight: 100~5000g. (Easy to change capacity by simply changing the auger).

Application:

Automatic milk powder tin can filling and sealing machine (LF-PJ-06), it is Designed for Tin Can metering filling and sealing, suitable for various kinds of powder and granular products into bottles/cans, such as, Milk powder, Chinese / Western medicine powder, food powder and chemical powder etc.

Package weight:

100~5000g. (Easy to change capacity by simply changing the auger).

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

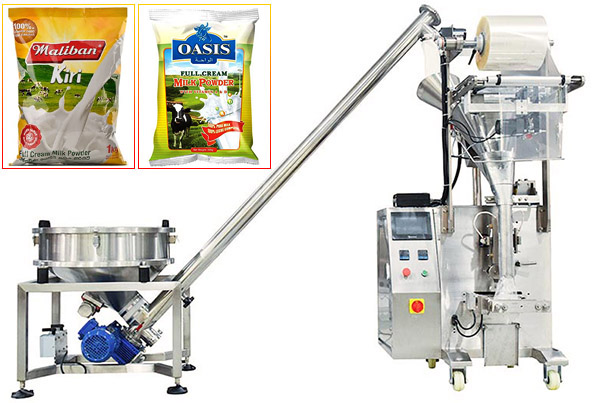

Packaging Samples

| Model | LF-PJ-06 |

Production capacity | 30-60 bottles/min. |

Material | 304 SST |

Package weight | 100~5000g |

Packaging accuracy | 100~5000g<=±1.5g |

Total power | 2.3KW |

Power supply | 380V,50-60Hz |

Weight | 280KG |

Dimension | 850(L)*1200(W)*1800(H)mm |

1. Filling machine →capping machine (or sealing machine) → bottle aluminum foil sealing machine → labeling machine → inkjet machine → Chain conveyor belt → packing platform, according to the requirements of the product selection pipeline configuration;

2. The entire production line of the machine for the appearance of all stainless steel, all the machinery structure are in accordance with the selection of food and drug hygiene standards;

3. The whole line of equipment according to GMP standard design, fully meet the national food and drug health requirements. The real line of the fully automated action to ensure that the entire production process will not contact the product staff, the production process is completely transparent and more reliable;

4. And the material in contact with the inner wall of the container are polished, often wash the structure of the use of easy to split pieces of connection to ensure that shift or change the product when dealing with hygienic convenience;

5. To the factory site survey, field design the best production program; free production line of other aspects of technical support.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail